- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Mingxin

-

Voltage:

-

380V/220V/415V

-

Dimension(L*W*H):

-

2300*1250*2650mm

-

Motor Power (Kw):

-

55

-

Power (kW):

-

90

-

Weight (KG):

-

1400 KG

-

Marketing Type:

-

New Product

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

stalk, rice husk, agri waste, wood sawdust

-

capacity:

-

1500kg/h

-

rotation speed:

-

1450r/min

-

Moisture of raw material:

-

15-20%

-

pellet temperature:

-

80-100℃

-

mould material:

-

special alloy

-

Final product:

-

4-12mm

-

Name:

-

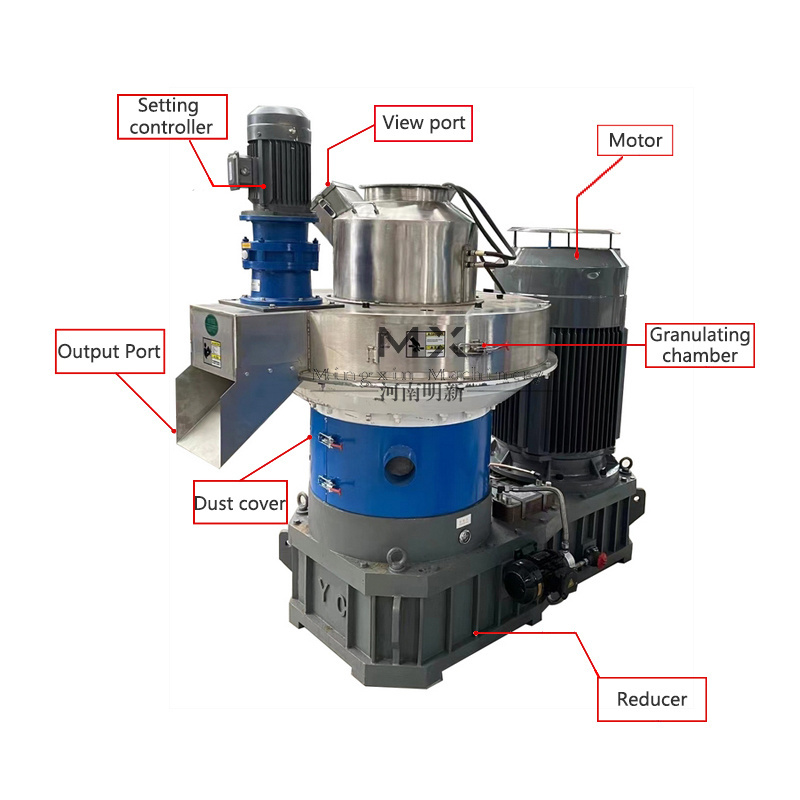

Ring Die Alfalfa Sawdust Biomass Pelletizer Wood Pellet Machine

-

Color:

-

Customer's Request

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

550 - 4200 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingxin

-

Voltage:

-

380V/220V/415V

-

Dimension(L*W*H):

-

2300*1250*2650mm

-

Motor Power (Kw):

-

55

-

Power (kW):

-

90

-

Weight (KG):

-

1400 KG

-

Marketing Type:

-

New Product

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

stalk, rice husk, agri waste, wood sawdust

-

capacity:

-

1500kg/h

-

rotation speed:

-

1450r/min

-

Moisture of raw material:

-

15-20%

-

pellet temperature:

-

80-100℃

-

mould material:

-

special alloy

-

Final product:

-

4-12mm

-

Name:

-

Ring Die Alfalfa Sawdust Biomass Pelletizer Wood Pellet Machine

-

Color:

-

Customer's Request

1-15 Tons/H biomass wood pellet mill biomass pellets making machine

Biomass pellet function will be agricultural and forestry processing waste such as wood chips, straw, rice husks, bark and other biomass as raw materials, through pretreatment and processing, solidified into high-density pellet fuel, is the ideal fuel to replace kerosene, can save energy and reduce emissions, with good economic and social benefits. It is a kind of efficient and clean renewable energy.

|

Model

|

Power

|

Capacity

|

Supporting facilities

|

|

450

|

55kw

|

0.8T/h

|

Butter pump, dust removal paper, soft cabinet

|

|

560

|

90kw

|

1-1.2T/h

|

|

|

580

|

110kw

|

1.5-1.8T/h

|

|

|

650

|

132kw

|

1.8-2.2T/h

|

|

|

700

|

160kw

|

2.5-3T/h

|

|

|

760

|

185kw

|

2.8-3.2T/h

|

|

|

850

|

220kw

|

3.5-4T/h

|

|

|

880

|

250kw

|

4.5-5T/h

|

|

Advantages of 1-15 Tons/H biomass wood pellet mill biomass pellets making machine

1.High automation, No need to take care.

In the process of operation, the control panel, tablet computer and mobile APP can be used to monitor the temperature of critical parts and the electric current of the equipment.

2.Casting material of gearbox with high stability.

Gearbox shell of wood pellet machine adopts casting. Weight of shell is 2.5t. Castings have advantages of good rigidity, good heat dissipation, Low heat distortion and high stability.

3.Parallel vertical installation reduce energy consumption loss.

The motor and main shaft of wood pellet machine supplier are parallel vertical installed , which can reduce energy consumption

loss in the process of transmission, more output power, higher transformation of energy efficiency.

Therefore, the wood pellet production line is a promising and lucrative project.

Before order:

Answering Customers' Questions:

According to our customer's question by email or telephone, we will provide a patient customer' service.

For example: In the beginning of communication, customers will consulting some details about our pellet machine or our company, and we will provide a professional answers for customers understand us better.

Technology Guidance:

Our pellet machine are all customized products, our sales manager will work together with our engineer provide a reasonable solution just for our customers condition.

Product Recommend:

Pellet machine have totally over 100 products to fit our customers' various requirement. So we will help our customers choose several products according our customer's detial working condition, suce as application, environment, working frequency and so on.

Design Drawings:

We will design drawings for customers' reference.

Making offer: According to customers purchase quantity, making a good offer with detial solutions.

After order:

Delivery Time:

After signing the contract and recieving the deposit, the production will take 15~20 working days.

Order Tracking:

After the deposit recieved, there will be a professional team tracking the order from production to package and shipment.

Pellet machine Testing:

All the materials are purchased from high quality supplier in China or the world, beyond this, we also make commissioning and test before packaging to avoid the trouble back.

After-sale Service:

Warranty Period:

We provide 12 month warranty for main body. Within 12 month, there is any quality problem with the main body(not including the wearing parts), we will arrange our professional engineers to provide requirement service.

Installation Service:

If customers don't need our engineers for installation, we will provide Remote Advisory Services. Also we could arrange engineers to provide installation service if customer need.

Periodic follow up:

For pellet machine serving situation. Collecting customers comment, develop better products and service.

1. Q: General questions to design the production line for you?

A:

1. What is your raw materials? (to confirm mould pressure ratio of machines )

2. What is the moisture content of your raw material?

3. How many output capacity do you want per hour / month/ year?

Note:

If the moisture is high, you need a dryer, becuase the suitable moisture content to enter pellet machine is 13-15%. And please provide us above detailed information, then we would design the most suitable production line with reasonble offers.

2. Q: How long is your guarantee?

A:

12 months warranty but except quick waering parts.

3. Q: Will you send engineers to install the machines?

A:

Of course. Our company has professional installation engineers team and specialized after-sale service team. When the machines arrive your factory, we will send our installation engineers to your factory at once. Our engineers will help you to install the machines and training your workers how to operate the machines and mentain the machine,

4. Q: Voltage requirement ?

A:

Our machines can use 380V, 3phase or customized.