Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

367

-

Brand Name:

-

RMGR

-

Product name:

-

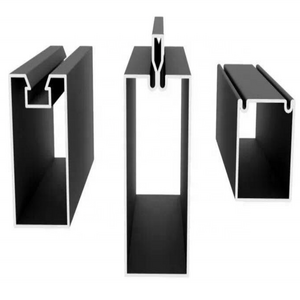

6063 t5 extruded aluminum profile for window and door

-

Material:

-

Aluminum alloy 6063/6061/6005/6060/6463/6082 T5/T6

-

Surface treatment:

-

Anodized Finish

-

Length:

-

Custom Size

-

Technology:

-

Extruded +CNC Precision Machining + Surface Treatment

-

Keyword:

-

aluminum profile for window and door

-

Skype:

-

rosa_ding2010

-

Whatsapp/wechat:

-

+86 15850169295

Quick Details

-

Grade:

-

6000 Series

-

Tolerance:

-

±1%

-

Place of Origin:

-

Jiangsu, China

-

Model Number:

-

367

-

Brand Name:

-

RMGR

-

Product name:

-

6063 t5 extruded aluminum profile for window and door

-

Material:

-

Aluminum alloy 6063/6061/6005/6060/6463/6082 T5/T6

-

Surface treatment:

-

Anodized Finish

-

Length:

-

Custom Size

-

Technology:

-

Extruded +CNC Precision Machining + Surface Treatment

-

Keyword:

-

aluminum profile for window and door

-

Skype:

-

rosa_ding2010

-

Whatsapp/wechat:

-

+86 15850169295

Product Description

|

Product Name

|

lowest factory price 6063 t5 extruded window door architecture building extrusion aluminum profile

|

|

Material

|

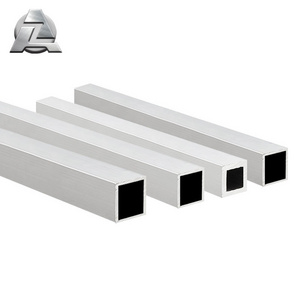

extrusion aluminum 6063-T5,6061-T6.(al,mg,si0.5,f22)

|

|

Detailed Size

|

As the below drawing,or as per custom design

|

|

Max Aspect Ratio( Fin Height / Fin Gap)

|

More than 20 times aspect ratio heatsink can be extruded by 800 Tons--6000 Tons extruding machine by most advanced technology

|

|

Max Width

|

500mm+/Ultra wide extruded heatsink can be made by our unique friction welding technology

|

|

Standard Mold Qty

|

30,000+ sets standard molds in stock for your option,saving your R&D cost

|

|

Sample Service

|

Samples with different sizes are availabe for prototypes test within 1 week

|

|

Production Process

|

H13 Mould-Profiles Extruding---Cutting---CNC Machining(Milling, Turning,Drilling,Tapping)---Deburring--- Cleaning--- Inspecting--Packing

|

|

Surface Treatment

|

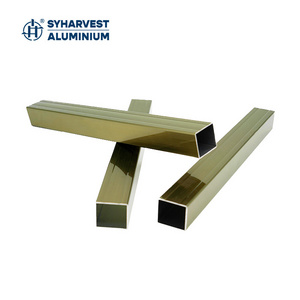

Degreasing,(Black) Anodizing,Sand Blasting,Painting,Chromating and Laser marking,powder coating.

|

|

Reference Standard

|

GB/T 3190-2008,GB/T 14846-2008,ISO 2768

|

|

Experience

|

More than 20 years professional manufacturing experience

|

|

Application

|

LED Lighting,Inverter,Welding Machine,Communication Device,Power Supply Equipment,Electronic Industry,Thermoelectric Coolers/Generator,IGBT/UPS Cooling Systems,etc.

|

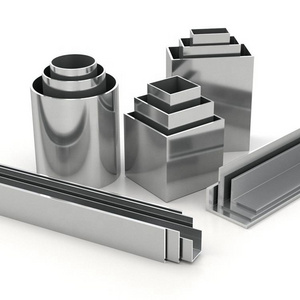

Related Products

100% Factory One-stop Production Process

H13 Extrusion aluminum mold-----Aluminium extrusion------ Fine cutting------Friction Stir Welding

------

CNC machining---- Deburring-----Surface Treatment (Anodized /Spray paint/ Dusting /Laser /Silk screen printing/ rendition etc) ------ Package ------ Shipment.

Inquiry

CAD/3D Drawings or samples.

Drawing Confirmation

CAD/3D drawing get approval from customer.

Mould Design And Making

20+years professional experience

Specialize in making high fin heatsink

Specialize in making high fin heatsink

Samples confirmation

Samples sent after factory's inspection -And get approval from customers.

Mass Production-E xtruded profile

Start mass production according to confirmed samples.

10+sets devices,range from 800 Tons to 10000 Tons extruding machines(express).

Quality Inspection

Check size for first finished batch aluminum profile.

Inspect all the material sizes before cutting and acnc machining.

Fine Cutting

Fine cutting according to customer's requests.

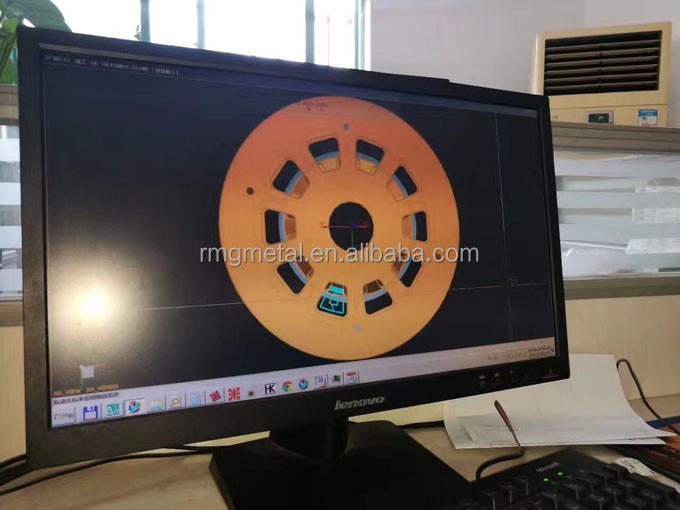

Precision CNC machining

Cutting,Drilling,Tapping,Chamfering,Milling and other CNC Machining requested.

Second Time Quality Inspection

Inspect all the machining sizes,holes at first time.

Surface treatment

Degrease,Black or Natural anodizing,Sandblasting,Painting,Chromating and Laser marking,powder coating.

Third time Quality Inspection

Inspect all the sizes,holes and appearance before shipment

Good Package and delivery

EPE+cartons+pallet protection

Suitable for sea or air shipment.

Suitable for sea or air shipment.

Delivery on time according to customer's requests.

Factory

ONE-STOP Customized

Service

1.Supply One-stop service from mold design and manufacturing to aluminium profile production.A lot of exist molds in stock, if there is no suitable one, we can extruded according to drawings or samples.

2.Products widely cover LED lights, solar lights,New energy,Inverter,Welding machine,Communication Device,Power Supply Equipment,Electronic Industry,Generator,IGBT/UPS Cooling systems,Electronic ,Automotive,Machinery, military, medical machinery, refrigeration ect.

CUSTOM

ALUMINUM EXTRUSION

1.More than 20 times aspect ratio heatsink can be extruded by 800 Tons--6000 Tons extruding machines by most advanced technology.

2.Large size hat sink extrusion expert

Cross section capabilities max to 550mm.

CNC MACHINING

ALUMINUM

1.Many CNC machining centers in our factory,products with

highly accurate and quality parts to meet even your most stringent requirements.

2.Quotes in seconds , custom parts delivered in days.

Main Categories

Packing&Shipping

FAQ

Q: What characteristics make a heatsink a good one?

A: High heatsink surface;Good aerodynamics;Good thermal transfer within the heatsink;Perfect flatness of the contact area;Good mounting method.

A: High heatsink surface;Good aerodynamics;Good thermal transfer within the heatsink;Perfect flatness of the contact area;Good mounting method.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the heatsinks are in stock. or it is 20-30 days for mass production

Q: What's your advantages compare with other suppliers?

A: Factory one-stop customized processing from extrusion mould to finished products with 20yesrs experiece! (extrusion mould, extrusion profile, cutting, CNC, anodize).

Q: What is your terms of payment ?

A: Usually 100% payment before shipment.For regular customers,the terms can be nogotiated.

If you have any other questions,please feel free to contact us.

A: Generally it is 5-10 days if the heatsinks are in stock. or it is 20-30 days for mass production

Q: What's your advantages compare with other suppliers?

A: Factory one-stop customized processing from extrusion mould to finished products with 20yesrs experiece! (extrusion mould, extrusion profile, cutting, CNC, anodize).

Q: What is your terms of payment ?

A: Usually 100% payment before shipment.For regular customers,the terms can be nogotiated.

If you have any other questions,please feel free to contact us.

Hot Searches