- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jishengya

-

Model Number:

-

MY004

-

Import or not:

-

No

-

Item No.:

-

MY004

-

Implementation standard:

-

Fineness of 325 mesh powder

-

CAS:

-

International color card

-

Scope of use:

-

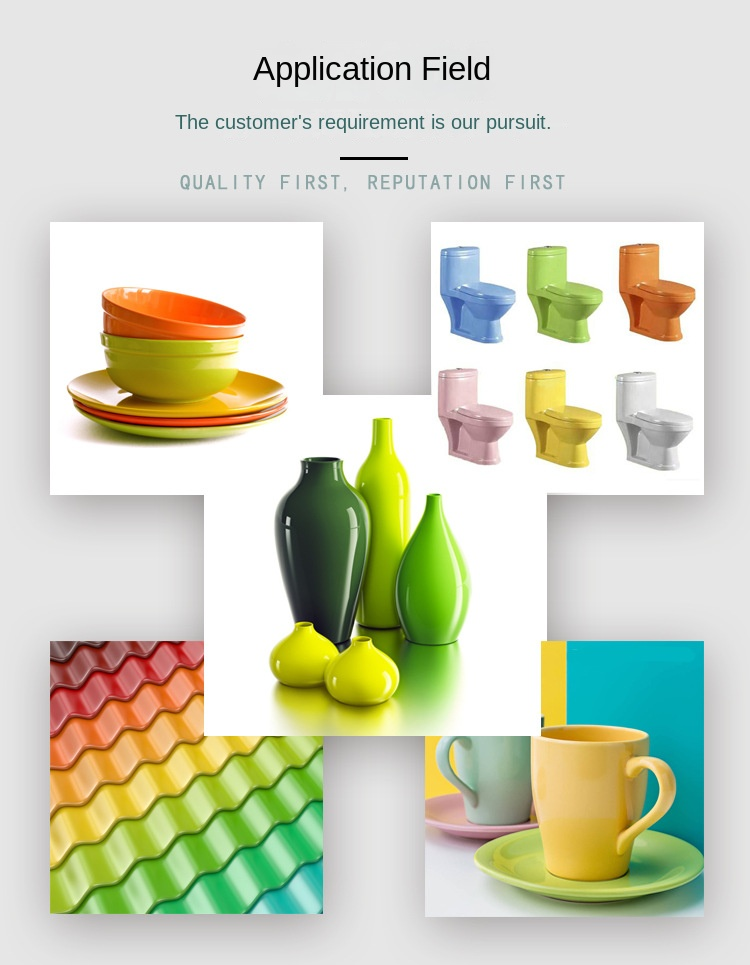

Daily use porcelain, ceramic tile, craft porcelain, bathroom, etc.

-

Special service:

-

Waterproof packaging sample customization

-

Are hazardous chemicals:

-

No

-

Applicable firing atmosphere:

-

Oxidation and reduction

Quick Details

-

CAS No.:

-

N/A

-

Other Names:

-

cobalt-chromium black

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jishengya

-

Model Number:

-

MY004

-

Import or not:

-

No

-

Item No.:

-

MY004

-

Implementation standard:

-

Fineness of 325 mesh powder

-

CAS:

-

International color card

-

Scope of use:

-

Daily use porcelain, ceramic tile, craft porcelain, bathroom, etc.

-

Special service:

-

Waterproof packaging sample customization

-

Are hazardous chemicals:

-

No

-

Applicable firing atmosphere:

-

Oxidation and reduction

Product Description

Specification

1.The color materials are all powdered and need to be prepared by themselves.

2.The pigment will precipitate and separate for along timeand due to the different proportion of each pigment, the proportion ot Glaze Water

Different, it is normal to deposit or agglomerate for a long time, stirring evenly and sieving

Just use it.

3The pictureshows fiaure photo ofthe dry piament and the firina effect of alaze on white porcelain clav.

Asaresult, the color will be diflerent from that of Glaze Water

4.The firing effect ofqlaze is related to the temperature, heating curve, work shape, placement position and

glazingthickness of kiln firingThecolor materials fired in different batches will also have slight differences.

There is no quarantee that the same effect can be burnt out in the details of this store. Please also conduc

samples before mass production for batch replacement. We hope to know it.

5.The glaze formula will be updated occasionally. Please confirm with the customer service before purchasing. The de

ailed pictures in the store will be updated in time. Please refer to the effect of the color plate on the picture

Packing & Delivery

Hot Searches