- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

zhitian

-

Voltage:

-

custom

-

Dimension(L*W*H):

-

240x210x170

-

Weight:

-

30 KG

-

Material:

-

Cr26,Nickel based alloy,SAM26

-

Processing Type:

-

Co-extrustion

-

Usage:

-

ABS

-

Application machine:

-

extruder

-

Center Distance:

-

63mm

-

Screw Diameter:

-

52mm

-

Product Type:

-

granulations

-

wear and corossion:

-

high anti-wear and anti-corossion

-

Marketing Type:

-

Other

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

Other

-

Screw Speed (rpm):

-

300 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

zhitian

-

Voltage:

-

custom

-

Dimension(L*W*H):

-

240x210x170

-

Weight:

-

30 KG

-

Material:

-

Cr26,Nickel based alloy,SAM26

-

Processing Type:

-

Co-extrustion

-

Usage:

-

ABS

-

Application machine:

-

extruder

-

Center Distance:

-

63mm

-

Screw Diameter:

-

52mm

-

Product Type:

-

granulations

-

wear and corossion:

-

high anti-wear and anti-corossion

-

Marketing Type:

-

Other

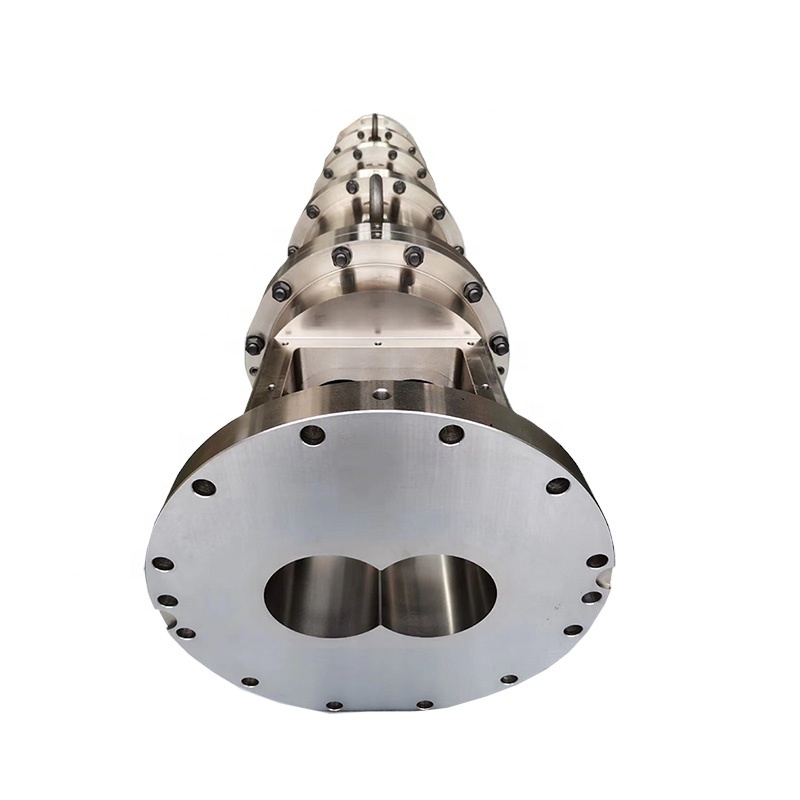

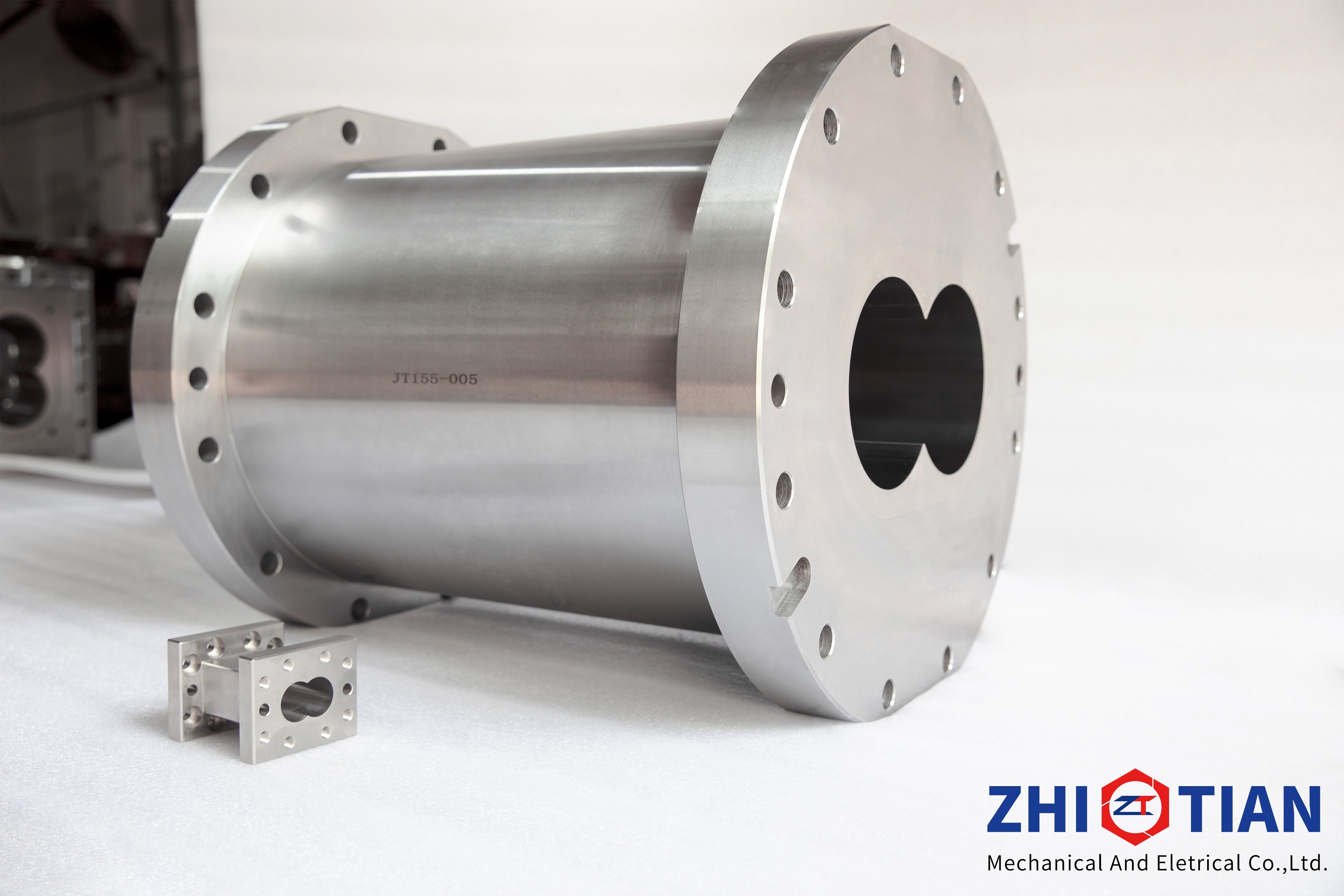

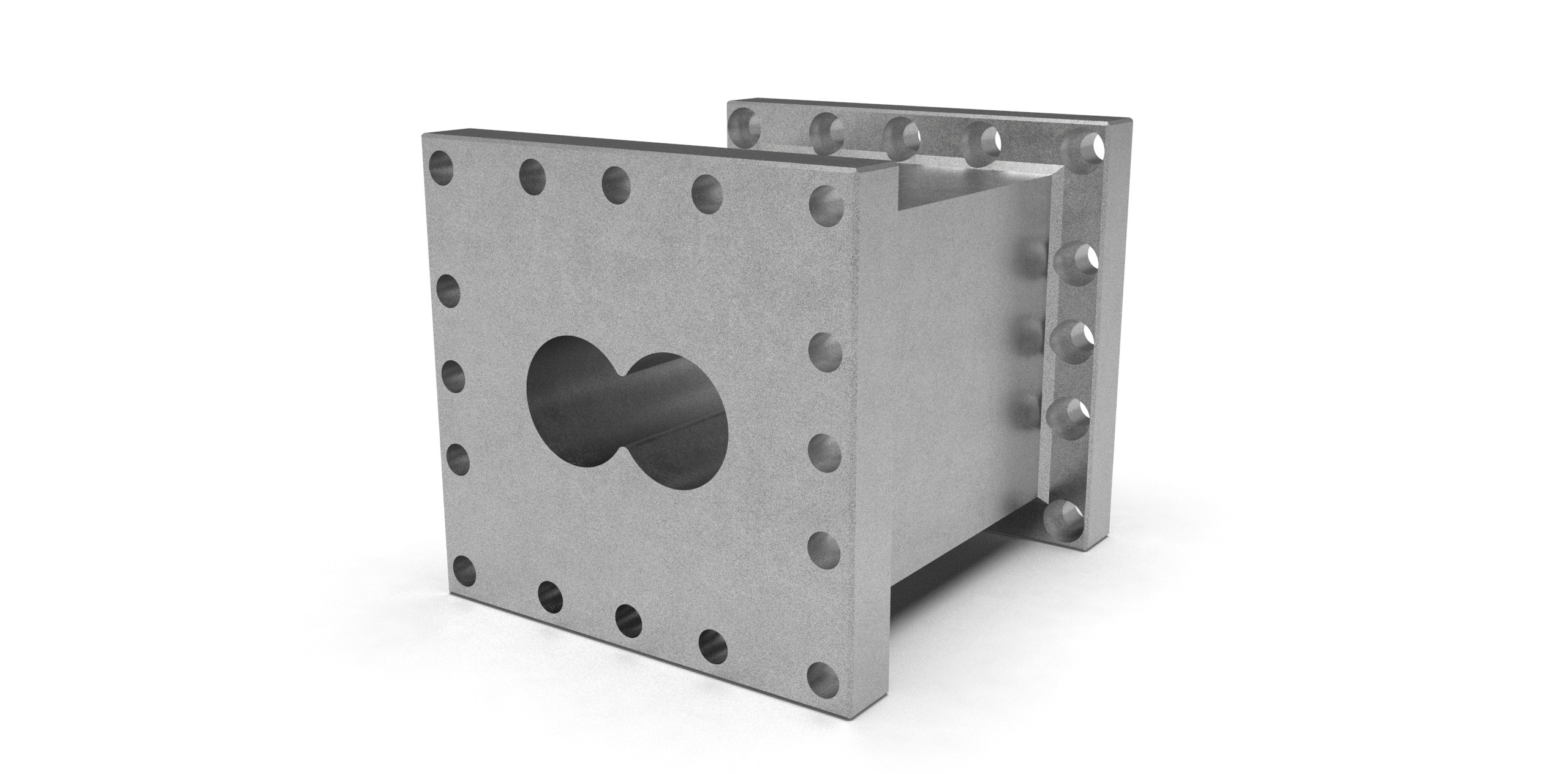

Products Description

|

Color

|

Metal

|

|

Standard

|

GB ISO 9001

|

|

Model

|

Type 20/30/35/36/40/50/52/53/58/60/65/75/85/92/95/110/125/135

|

|

Brand

|

zhitian

|

|

Quality

|

High wear-resistance and corrosion-resistance

|

|

Used

|

For twin screw extruder

|

Efficient and stable, widely used in industries:

The twin-screw extruder barrels produced by zhitian are widely used in plastics, rubber, chemicals, food, new energy and other industries. Countless extruders on the market use our accessories. And efficient and stable operation, these prove our strength.

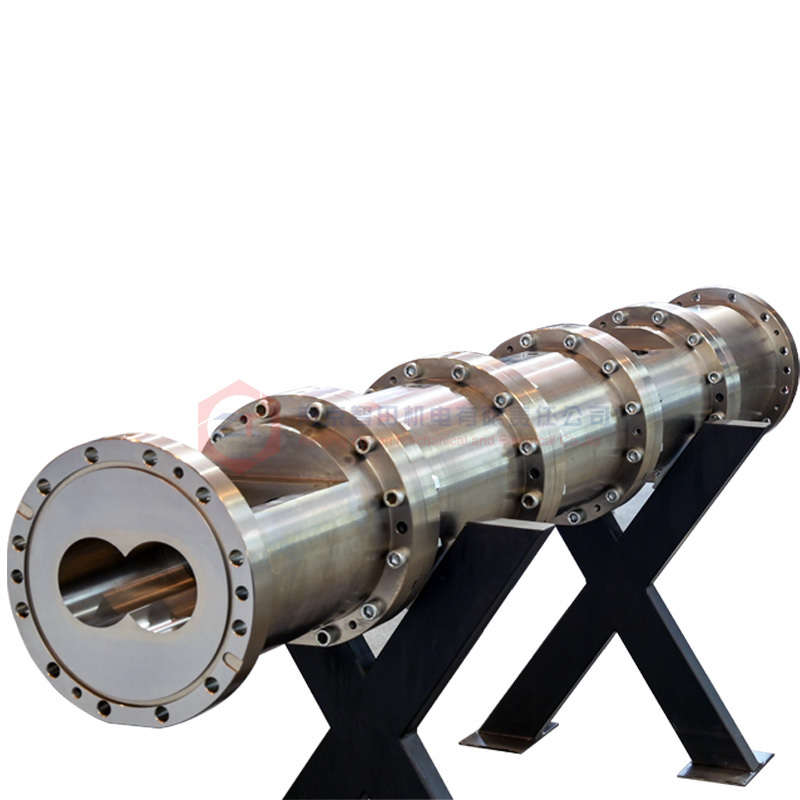

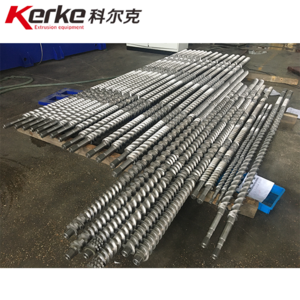

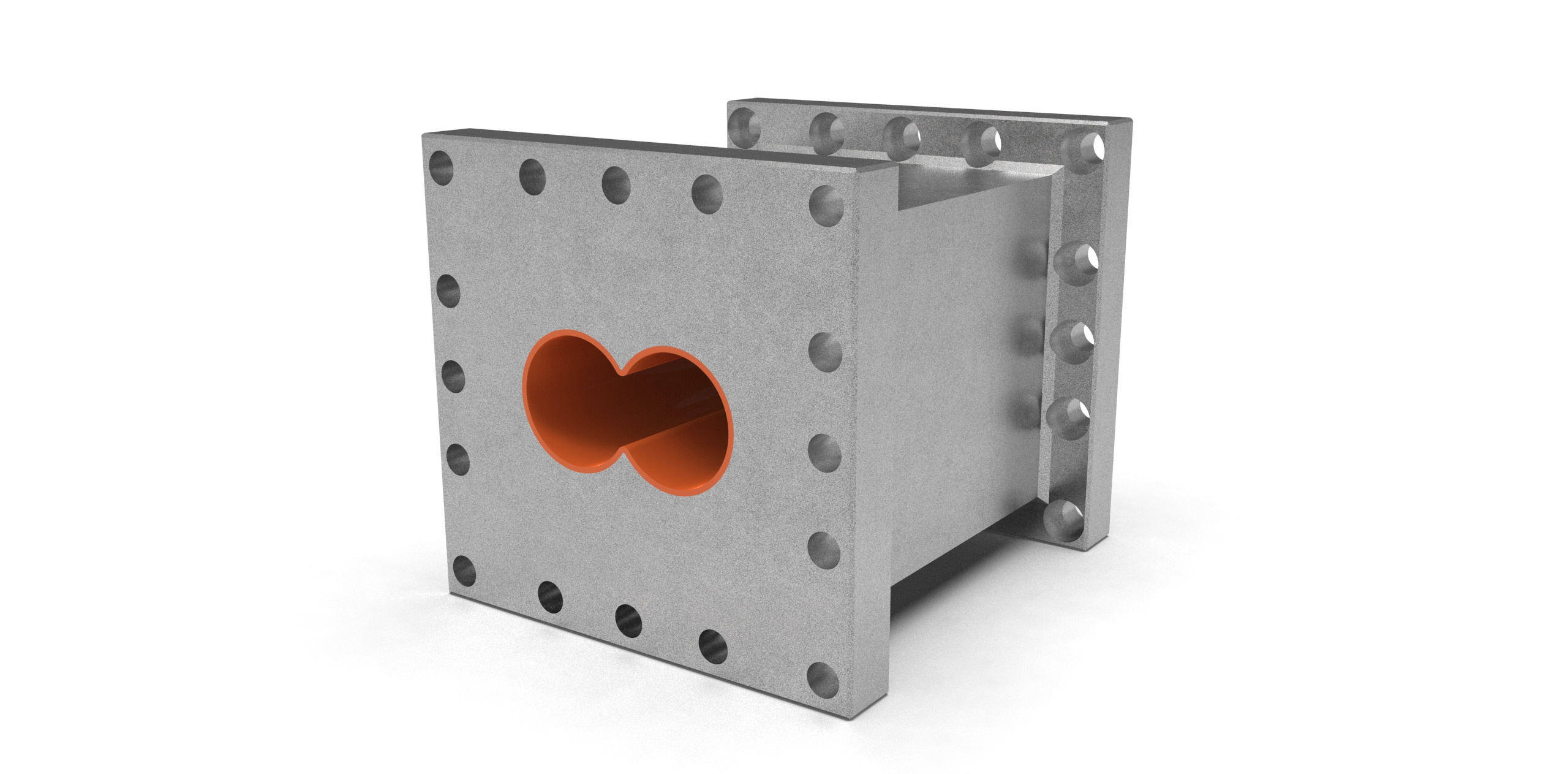

Advanced "building block" design:

The main screw and barrel of the split twin-screw extruder adopt an advanced "building block" design. The screw is composed of various screw blocks installed on the mandrel and barrel lining, forming a sleeve that can be adjusted according to different screw blocks. This design allows the screw component structure to be flexibly combined according to the process requirements of the material variety to achieve material transportation, refinement, shearing, and discharge. This effectively solves the difficult-to-consider contradiction between the versatility and specificity of the screw, achieving the purpose of one machine with multiple uses.

Reduced maintenance costs:

Another advantage of the "building block" design is that worn screw and barrel components can be partially replaced, preventing the entire screw or barrel from being scrapped and greatly reducing maintenance costs. This means you save time and money without having to replace the entire unit or buy an entirely new barrel.

Continuous material research and development:

zhitian has its own powder metallurgy equipment and has developed materials such as

ZT615

nickel-based alloy and

ZT625

nickel-based alloy tungsten carbide, which are widely used in wear-resistant and corrosion-resistant usage scenarios.

|

Type Of Barrels

|

Materials

|

|

Solid Barrel

|

Hastelloy-C Alloy,

38CrMoAla,

30

4/316/316L Stainless Steel

|

|

Direct Compound Barrel

|

ZT610 Ni60 Based+Cu,

ZT615 Ni60 Based,

ZT625 Ni60 Based+Tungsten carbide,

HIP Cobalt Based+Tungsten carbide.

|

|

Complete Liner Barrel

|

38CrMoAla Liner,

440C Stainless Steel Liner,

Cr12MoV Liner,

SKD11/SKD61 Liner,

DC53 Liner,

W6Mo5Cr4V2 Liner,

ZTCr26 Liner,

SAM26/WR13 Liner,

CPM10V/WR5 Liner,

ZT610 Ni60 Based Liner+Cu,

ZT615 Ni60 Based Liner,

ZT625 Ni60 Based Liner+Tungsten carbide,

HIP Cobalt Based Liner+Tungsten carbide.

|

|

Compound Alloy Liner Barrel

|

S45C+ZT610 Ni60 Based Liner+Cu

S45C+ZT615 Ni60 Based Liner,

S45C+ZT625 Ni60 Based Liner+Tungsten carbide,

S45C+HIP Cobalt Based Liner+Tungsten carbide.

|

Products Show

Why choose Zhitian’s extruder barrel?

The screw barrel of a twin-screw extruder. We have extensive experience in twin-screw extruder screw barrels. Through continuous practice, we have developed a variety of new screw barrels, which, with different screw designs, greatly increase output and enhance service life. We also provide OEM services for well-known extruder complete machine manufacturers in the world. Zhitian is one of the best extruder barrel manufacturers in China.

Our Advantages

1. Long service life

2. Material: Choose materials with high wear resistance, corrosion resistance or both according to customer needs.

3. The professional technical team can not only provide timely and accurate sample measurement and design, but also provide technical services for component combinations.

4. A complete modern management system ensures that customers receive 100% qualified products. At the same time, the quality of each product is traceable.

5. Wide range of applications: The range of use is universal and can be applied to the processing of a variety of materials.

Hot Searches