- Product Details

- {{item.text}}

Quick Details

-

Power:

-

11KW

-

Dimension(L*W*H):

-

1000*300*1100MM

-

Name:

-

Rovan Shot Blasting Machine

-

Feature:

-

Non-Toxic

-

Working Width:

-

550mm

-

Concrete Surface Cleaning Efficiency:

-

80m/h

-

Steel Shot Diameter:

-

1.5-1.8mm

-

Walking Speed:

-

0.5-33m/Min

-

Diameter of Dust Pipe:

-

150mm

-

Steel Shot Consumption:

-

10G/M

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SanyiBQ

-

Weight (KG):

-

150 KG

-

Power:

-

11KW

-

Dimension(L*W*H):

-

1000*300*1100MM

-

Name:

-

Rovan Shot Blasting Machine

-

Feature:

-

Non-Toxic

-

Working Width:

-

550mm

-

Concrete Surface Cleaning Efficiency:

-

80m/h

-

Steel Shot Diameter:

-

1.5-1.8mm

-

Walking Speed:

-

0.5-33m/Min

-

Diameter of Dust Pipe:

-

150mm

-

Steel Shot Consumption:

-

10G/M

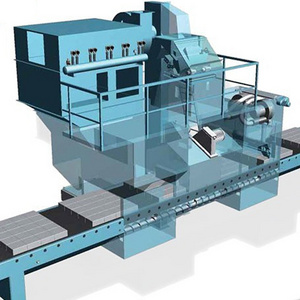

Factory Price Road shot blasting machine Polishing Blasting Floor Concrete Surface Shot

Road Surface shot blasting machine

can successively clear away the concrete surface laitance and impurities, and cando polishing processing to the concrete surface, make its surface achieve uniform roughness. Greatly improve the adhesive strength of the waterproof layer and concrete base, so that better combine the waterproof layer and deck.

Products Description

Products Description

|

Model

|

ID-RA270

|

ID-RA550

|

ID-RA850

|

|

Working width

|

270mm

|

550mm

|

800mm

|

|

Walking speed

|

0.5-20m/min

|

0.5-33m/min

|

0.5-33m/min

|

|

Concrete(steel) surface cleaning efficiency

|

80m³/h

|

80m³/h

|

160m³/h

|

|

Diameter dust pipe

|

120mm

|

150mm

|

150mm

|

|

Steel shot diameter

|

1.2-1.5mm

|

1.5-1.8mm

|

1.5-1.8mm

|

|

Steel shot consumption

|

10g/m²

|

10g/m²

|

10g/m²

|

|

Dimension

|

1000*300*1100mm

|

2050*725*1460mm

|

1950*1020*1550mm

|

|

Shot wheel diameter

|

200mm

|

200mm

|

200mm

|

Blast processing equipment is widely used in improving asphalt pavement roughness and friction coefficient, and improve surface adhesion, ensure traffic safety. At the same time also can remove the asphalt attachments (such as fuel, oil, etc.) is mainly used in the following aspects:

1. It is used to improve the asphalt pavement roughness and friction coefficient, so as to improve the adhesion of the road surface and ensure the safety of driving. At the same time, asphalt fixtures (such as fuel, oil, etc.) also have nowhere to run, thus improving the skid resistance of the pavement

2. Anti-corrosion coating of the steel bridge deck

The application of shot blasting in the anticorrosive coating of steel bridges is undeniable. Most Bridges under construction and completed construction use a shot blasting machine for surface cleaning and roughness treatment prior to antiseptic primers or other sprays

3. Tunnel maintenance

Due to the consideration of waterproof, fire resistance, and oil resistance of materials, cement concrete is generally used for the pavement inside the tunnel. But it also puts forward a higher requirement for the anti-skid performance of the long tunnel road surface. Shot blasting technology is a treatment method with simple construction, small equipment input, remarkable effect, and environmental protection.

4. Preventive maintenance of airport runways

The use of road shot blasting machines makes the removal of tread marks and marking on concrete and asphalt runway easy and simple. The treatment range of the road blasting machine is to remove the tread (rubber), remove the marking, restore and increase the surface roughness of the airport runway and increase the friction coefficient of the runway. Moreover, in the process of treatment, the road blasting is more orderly.

5. Municipal roads and paved roads

All kinds of road paving in the city can use the shot blasting machine for cleaning treatment, and remove the road signs and markers, for busy intersections, the road surface can be brushed, improving the pavement roughness and friction coefficient. Reduce problems in pavement construction. Therefore, the auxiliary role of road blasting machines in urban.

1. It is used to improve the asphalt pavement roughness and friction coefficient, so as to improve the adhesion of the road surface and ensure the safety of driving. At the same time, asphalt fixtures (such as fuel, oil, etc.) also have nowhere to run, thus improving the skid resistance of the pavement

2. Anti-corrosion coating of the steel bridge deck

The application of shot blasting in the anticorrosive coating of steel bridges is undeniable. Most Bridges under construction and completed construction use a shot blasting machine for surface cleaning and roughness treatment prior to antiseptic primers or other sprays

3. Tunnel maintenance

Due to the consideration of waterproof, fire resistance, and oil resistance of materials, cement concrete is generally used for the pavement inside the tunnel. But it also puts forward a higher requirement for the anti-skid performance of the long tunnel road surface. Shot blasting technology is a treatment method with simple construction, small equipment input, remarkable effect, and environmental protection.

4. Preventive maintenance of airport runways

The use of road shot blasting machines makes the removal of tread marks and marking on concrete and asphalt runway easy and simple. The treatment range of the road blasting machine is to remove the tread (rubber), remove the marking, restore and increase the surface roughness of the airport runway and increase the friction coefficient of the runway. Moreover, in the process of treatment, the road blasting is more orderly.

5. Municipal roads and paved roads

All kinds of road paving in the city can use the shot blasting machine for cleaning treatment, and remove the road signs and markers, for busy intersections, the road surface can be brushed, improving the pavement roughness and friction coefficient. Reduce problems in pavement construction. Therefore, the auxiliary role of road blasting machines in urban.

Product Overview

Product Overview

The pill material is stored in the lower part of the separation tank by the feed tube into the shot blasting parts shot blast

wheel at high-speed relation by blasting machine motor, the pill is accelerated to 80m/s clean the surface, high-speed energy pills material impact work surface. Under negative pressure pills, materials and dust were back to the dust separation box, where they completed the separation of pill material and dust and impurities, good pill material into the shot blasting parts continue to use, and dust and impurities are filtered and slipped into closed set dust box waiting to be processed.

wheel at high-speed relation by blasting machine motor, the pill is accelerated to 80m/s clean the surface, high-speed energy pills material impact work surface. Under negative pressure pills, materials and dust were back to the dust separation box, where they completed the separation of pill material and dust and impurities, good pill material into the shot blasting parts continue to use, and dust and impurities are filtered and slipped into closed set dust box waiting to be processed.

Dust Removal System

With a better understanding of environmental awareness, protection, and management, improving the environment has been the consensus of the whole society. With our long-term research, analysis, and practice to get shot blast machine industry experience, our factory makes a new design with every shot blasting machine, we aim to improve our working conditions for employees and improve the comprehensive economic benefits. Dust removal system including dust collector, fan, fan piping, the connection pipeline between the filter and the main machine, etc.

The shot blasting machine is equipped with OMRON international brand Power protection device imported from Japan.

Notice: it keeps the Simpler operation, our concrete shot blaster with OMRON full protection power system in Japan. It can cut off the control system in 0.3 seconds and give a machine fault indication, thus avoiding the loss of the user, If a power failure occurs.

With a better understanding of environmental awareness, protection, and management, improving the environment has been the consensus of the whole society. With our long-term research, analysis, and practice to get shot blast machine industry experience, our factory makes a new design with every shot blasting machine, we aim to improve our working conditions for employees and improve the comprehensive economic benefits. Dust removal system including dust collector, fan, fan piping, the connection pipeline between the filter and the main machine, etc.

The shot blasting machine is equipped with OMRON international brand Power protection device imported from Japan.

Notice: it keeps the Simpler operation, our concrete shot blaster with OMRON full protection power system in Japan. It can cut off the control system in 0.3 seconds and give a machine fault indication, thus avoiding the loss of the user, If a power failure occurs.

Product packaging

Product packaging

1 unit was packed into an iron frame and then packed with 5 layers of corrugated carton. 4 strips reinforced the carton. the fix package guaranteed the machines were not damaged during transportation

Hot Searches