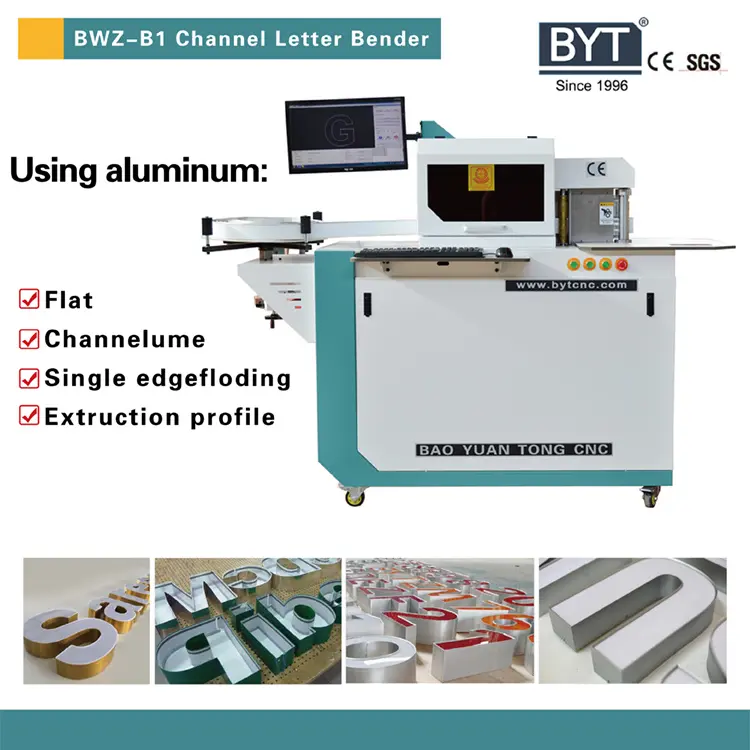

Application:

The application range of the Channel Letter Bending Machine is generally in the advertising industry. When the advertising company needs to do the luminous characters for the shops,it needs to use the channel letter bending machine to make the production. The channel letter bending machine can process many materials aluminum profiles, aluminum strip ) and does not damage the material.The processing precision is high and the speed is fast. The material thickness and tool adjustments are all adjusted by software,more convenient and quickly.

Technical datas:

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

300

-

Products name::

-

Channel letter bending bender machine

-

Model::

-

BWZ-B1

-

Operation principle::

-

High precision automatic feeding,trimming,notching and bendin

-

Available material::

-

Aluminum

-

Material thickness::

-

0.3-1.5mm

-

Material width::

-

10-180mm

-

Precision::

-

0.1mm/100Meter

-

Document format::

-

AI/DXF/PLT

-

Working Voltage::

-

220V 50HZ 1PH or Customized

-

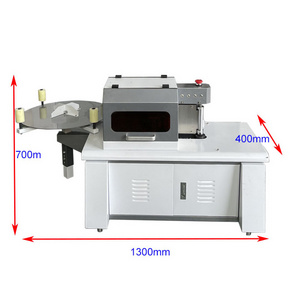

Overall size:

-

2100*800*1530mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BYTCNC

-

Year:

-

2024

-

Weight (KG):

-

300

-

Products name::

-

Channel letter bending bender machine

-

Model::

-

BWZ-B1

-

Operation principle::

-

High precision automatic feeding,trimming,notching and bendin

-

Available material::

-

Aluminum

-

Material thickness::

-

0.3-1.5mm

-

Material width::

-

10-180mm

-

Precision::

-

0.1mm/100Meter

-

Document format::

-

AI/DXF/PLT

-

Working Voltage::

-

220V 50HZ 1PH or Customized

-

Overall size:

-

2100*800*1530mm

Products Description

BWZ-B1 Alminum3D letter bender Channel Letter Bending Machine For acrylic metal signs making

|

Model

|

BWZ-B1

|

|

Function

|

Automatic feeding,slotting and bending

|

|

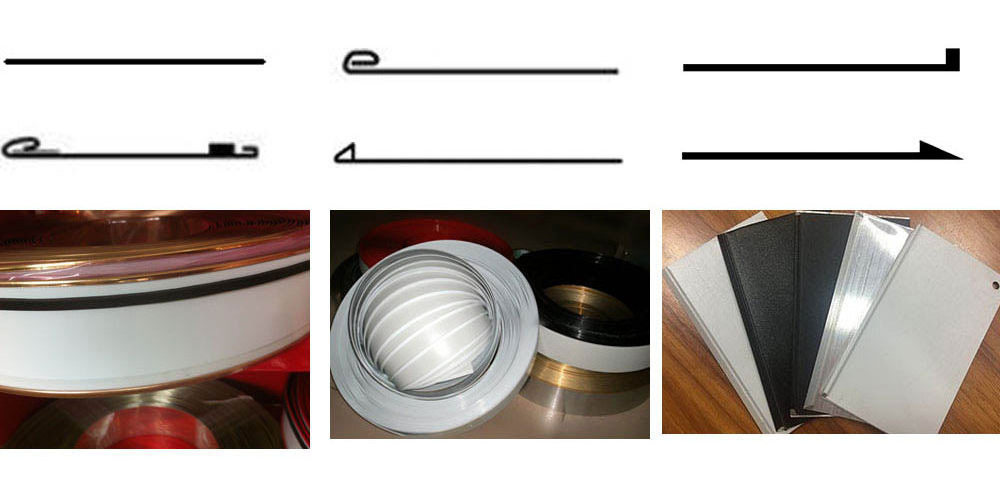

Applicable Material

Alu=Aluminum

|

Flat Alu,Folding Alu,Channelume

|

|

Material Width

|

Flat Alu:≤180mm Folding Alu:≤160mm

Channelume:70,90,110mm

|

|

Material Thickness

|

Aluminum:0.3~1.5mm

|

|

Bending Radius

|

7mm

|

|

Feeding

|

φ36mm feeding wheel+Guide material auxiliary+Encoder

|

|

Slotting System

|

Motor control

|

|

Bending

|

Coupled extrusion-Double copper shaft flat arc bender

|

|

Control System

|

ADT

|

|

Power

|

<1500W

|

|

Air Pressure

|

0.6MPa

|

|

File Format

|

Dxf, Ai,Plt

|

|

Working Voltage

|

220V/ 50-60HZ/1P

|

|

Net Weight(kgs)

|

270

|

|

Overall Size(mm)(L*W*H)

|

2100*800*1530

|

Whole machine advantage:

1.Whole machine

guarantee 2 years

, the motor

guarantee 3 years

2.Processing material

height 10-180mm, Thickness : 0.3-1.5mm.

3.All machining parts be

treated with hard chromium plating

,which is wear-resistant and corrosion-resistant, especially suitable for coastal areas.

4.1Using the most

advanced ADT operating software

, easy to learn, usually only after

1-2 hours

of training by our engineers ,customers can operate and use independently.

4.2.The software have

Length closed-loop control system

,the length precision

≤0.1mm

.

Feeding:

The feeding roller

diameter 36mm and install encoder,

ensure the feeding precision and speed.

Notching:

The stability, practicability and accuracy of cutting are guaranteed by the following structure.

20mm Taiwan guide rail

Motor lifting control cut not cylinder

More stable four-column design

Automatic adjust cutting depth

Bending:

Double cooper shaft flat arc bending device

,small radian beat and large radian extrusion molding ,processing

speed fast and don’t damage the material

,finish

80-100

M2/day.

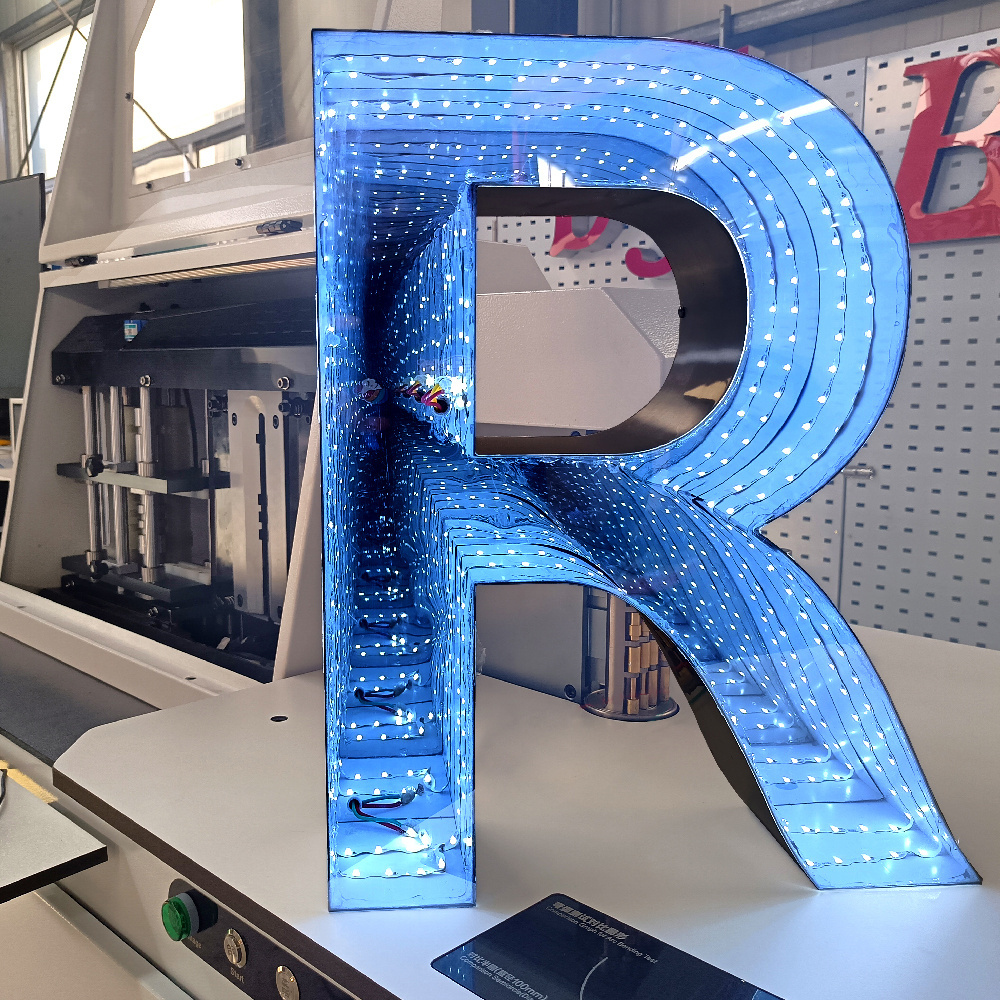

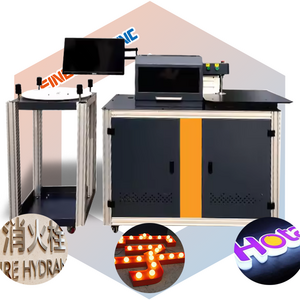

Customer Finish Samples

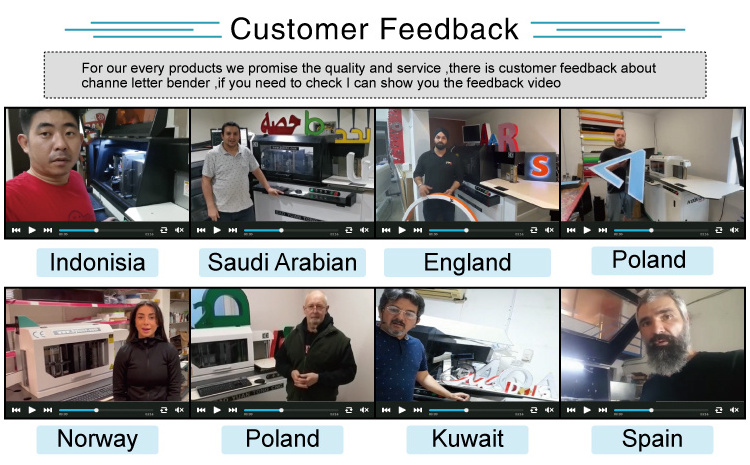

Customer feedback

Click below picture you will find

letter bender detail video

,it is our customer recently feedback our

CNC letter bending machine and laser welding machine

. it is our duty to provide good service to our every customer .

Related products

Our Service

Keep Quality and Service Be Our First Responsibility

Sales Service

1.Technical people have professional english ability and directly with customer communication.

2.24H/7D on line service , when you need we all will be here .

3.Before delivery , accept the international third party finish inspection .

4.Regular return visits to customers for technical guidance, and get high praise from customers.

5.For the products making , have professional technical engineer provide process guide .

Various Training Service

1.Provide U disk with detailed operation manual and video.

2.Via on line chat way service(QQ,whatsapp,wechat) for customer in any time.

3.Via teamviewer remote control software to provide on line guidance.

4. Customer come to our factory for learning how to operate the machines.

5.Engineer can go aboard for training if customer needed.

Hot Searches