- Product Details

- {{item.text}}

Quick Details

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BGB

-

Model Number:

-

BGB-835

-

Odor:

-

No pungent odor

-

Leveling:

-

self-leveling

-

Tensile strength:

-

Mpa ≥2.8

-

Tear strength KN/M:

-

≥6

-

Hardness Shore A:

-

30-40

-

Elongation %:

-

≥200

-

Line shrinkage %:

-

≤0.3

-

Color:

-

translucent milky white

Quick Details

-

CAS No.:

-

63394-02-5

-

Purity:

-

100%

-

Other Names:

-

Silicone rubber

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BGB

-

Model Number:

-

BGB-835

-

Odor:

-

No pungent odor

-

Leveling:

-

self-leveling

-

Tensile strength:

-

Mpa ≥2.8

-

Tear strength KN/M:

-

≥6

-

Hardness Shore A:

-

30-40

-

Elongation %:

-

≥200

-

Line shrinkage %:

-

≤0.3

-

Color:

-

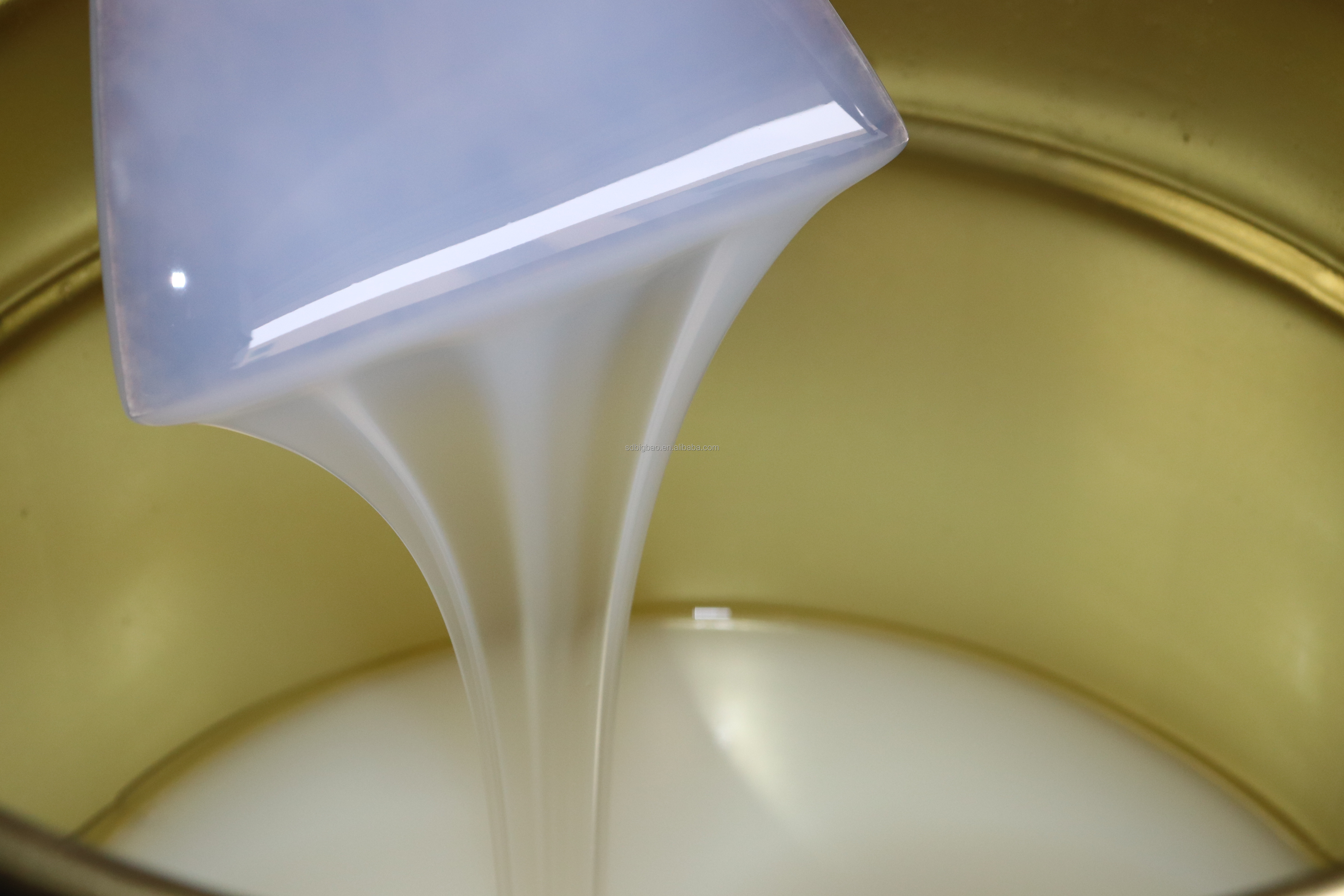

translucent milky white

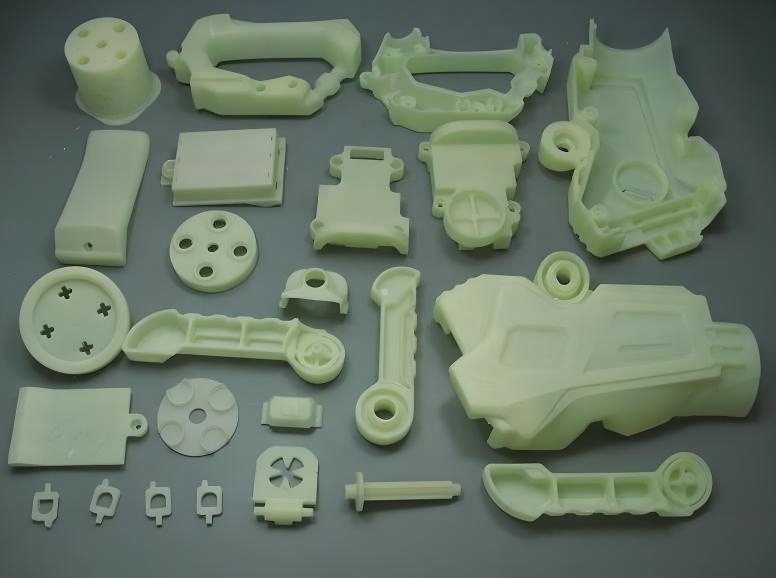

Silicone rubber series

BGB-835 Room temperature mold silicone rubber

Product Introduction

This product is a two-component room temperature vulcanized silicone rubber with excellent comprehensive performance. Easy to use, with high strength, good simulation, demolding ability, and high elasticity.

|

Serial Number |

Item |

Unit |

index |

|

1 |

appearance |

|

It should be a smooth and delicate viscous fluid, without coarse particles, lumps, or precipitates that are difficult to quickly and evenly disperse |

|

2 |

Colour |

|

milky white |

|

3 |

smell |

|

No irritating odor |

|

4 |

Density: Component A and Component B |

g/ cm³ g/ cm³ |

1. 20+0.05 1. 00+0. 05 |

|

5 |

Leveling property |

|

Self-leveling |

|

6 |

tensile strength |

Mpa |

≥ 3.2 |

|

7 |

tearing strength |

|

≥ 26 |

|

8 |

hardness |

shore A |

20 - 2 6 |

|

9 |

elongation |

% |

≥ 48 0 |

|

10 |

linear shrinkage |

% |

≤ 0.3 |

Usage

The weight ratio of component A to ethyl orthosilicate and catalyst can be selected in the range of 100:1.8-1.4. Increasing the ratio will shorten the operation time and accelerate the vulcanization rate.When in use, mix components A and B in proportion, and after the bubbles in the mixed rubber material are discharged, it can be cast or coated to make a film. Vacuum blasting technology can be used.

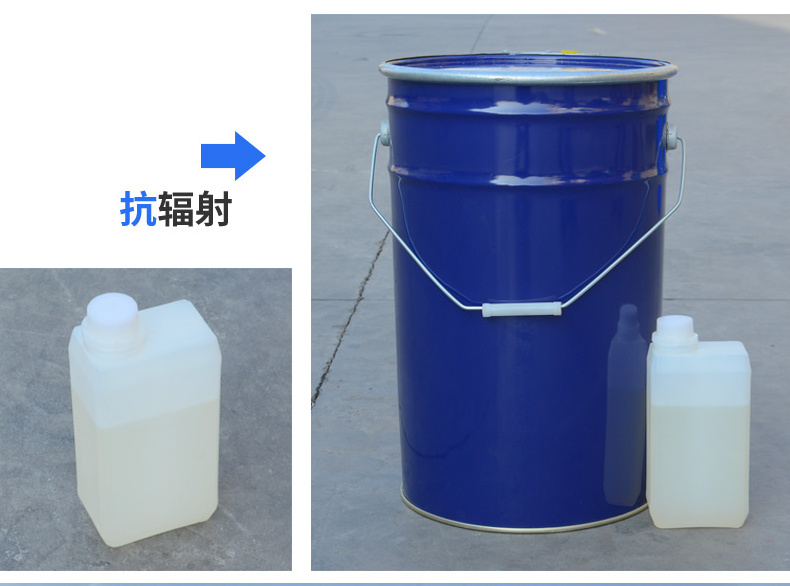

packaging and storage

Barrel packaging, net weight of component A 25kg, net weight of component B 0.8kg