- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0.1%~0.3%

-

SiC Content (%):

-

1.2%~1.4%

-

Place of Origin:

-

Shandong, China

-

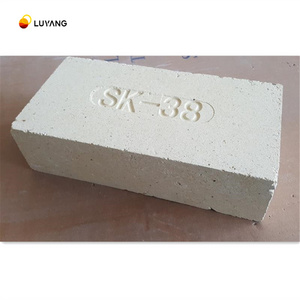

Model Number:

-

SK35,SK36,SK37,SK38,SK40

-

Brand Name:

-

JUCOS

-

Product name:

-

Hot sale wholesale firebrick price including high alumina firebrick

-

Color:

-

Yellow

-

Size:

-

Customizable

-

Bulk Density:

-

2.25~2.65g/cm3

-

Apparent porosity:

-

22%

-

Certifiacte:

-

ISO9001, CE, etc

-

Fe2O3:

-

2.0%

-

Cold crushing strength:

-

50MPa

-

Thermal linear expansion:

-

0.6

-

Applications:

-

Nonferrous Metal Furnace

Quick Details

-

SiO2 Content (%):

-

15%~45%

-

Al2O3 Content (%):

-

48%~85%

-

MgO Content (%):

-

0.8~1.2

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0.1%~0.3%

-

SiC Content (%):

-

1.2%~1.4%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK35,SK36,SK37,SK38,SK40

-

Brand Name:

-

JUCOS

-

Product name:

-

Hot sale wholesale firebrick price including high alumina firebrick

-

Color:

-

Yellow

-

Size:

-

Customizable

-

Bulk Density:

-

2.25~2.65g/cm3

-

Apparent porosity:

-

22%

-

Certifiacte:

-

ISO9001, CE, etc

-

Fe2O3:

-

2.0%

-

Cold crushing strength:

-

50MPa

-

Thermal linear expansion:

-

0.6

-

Applications:

-

Nonferrous Metal Furnace

Description Of High Alumina Brick

High alumina brick of over SK35 contain 46% to 80% Alumina content are made from raw materials of high degree of purity of Bauxite and fireclay. For serve under severe conditions, High alumina bricks have excellent mechanical strength, good resistance to thermal spalling, and are highly resistant to chemical attack by vilatile alkaies and some slag. Jucos manufacture and design high alumina bricks to meet the requirements of a great variety of service conditions through quality control.

Specifications Of Product

Alumina contents range from 46% to 80%

Widely used throughout metallurgical industry

Physical And Chemical Indicators Of Product

|

Brand

Properties

|

|

SK-40

|

SK-38

|

SK-37

|

SK-36

|

SK-35

|

|||||

|

Refractoriness (SK)

|

|

40

|

38

|

37

|

36

|

35

|

|||||

|

Apparent Porosity (%)

|

|

22

|

23

|

23

|

23

|

23

|

|||||

|

Bulk Density (g/cm3)

|

|

2.65

|

2.40

|

2.35

|

2.30

|

2.25

|

|||||

|

Cold Crushing Strength(MPa)

|

|

70

|

52

|

50

|

45

|

40

|

|||||

|

Thermal Linear Expansion(%) @1000deg

|

|

0.6

|

0.6

|

0.6

|

0.6

|

0.6

|

|||||

|

Permanent Linear Change(%) @1400degx2hrs

|

|

±0.2

|

±0.3

|

±0.3

|

±0.3

|

±0.3

|

|||||

|

Refractoriness under Load (℃) @0.2MPa

|

|

1,530

|

1,500

|

1,450

|

1,420

|

1,380

|

|||||

|

Chemical Composition(%)

|

Al2O3

|

80

|

72

|

60

|

50

|

46

|

|||||

|

|

Fe2O3

|

1.8

|

2.0

|

2.0

|

2.0

|

2.0

|

|||||

|

Main Applications

|

|

- Nonferrous Metal Furnace

- Rotary & Shaft Kiln - Various Incinerator - Reheating Furnace - Permanent Lining For EAF Ladle - General Industrial Furnace etc. |

|

|

|

|

|||||

Industry Application

Packing &Shipping

Hot Searches