- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

customization

-

Weight:

-

1000 KG

-

Place of Origin:

-

China

-

Voltage:

-

customization

-

Key Machines:

-

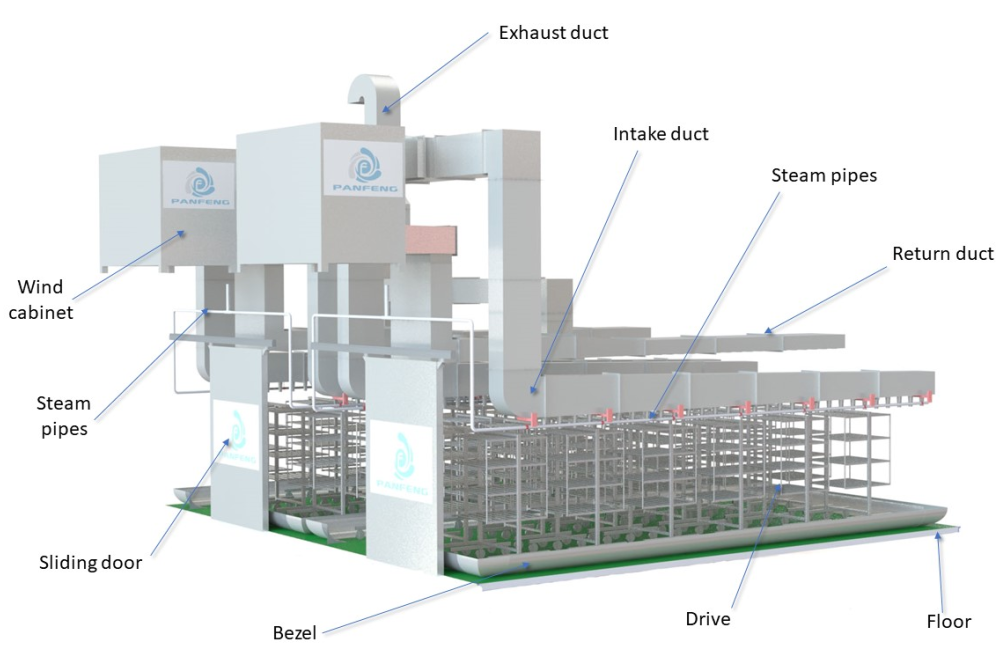

Fan Filter Unit, HEPA filter, Meat processing plant

-

Product Type:

-

meat, fermented meat, sausage

-

Application:

-

Meat Processing

-

Applicable Industries:

-

Fermented meat

-

Product name:

-

Sausage

-

Function:

-

Make the plant cleaner

-

Temperature:

-

2-40 ℃

-

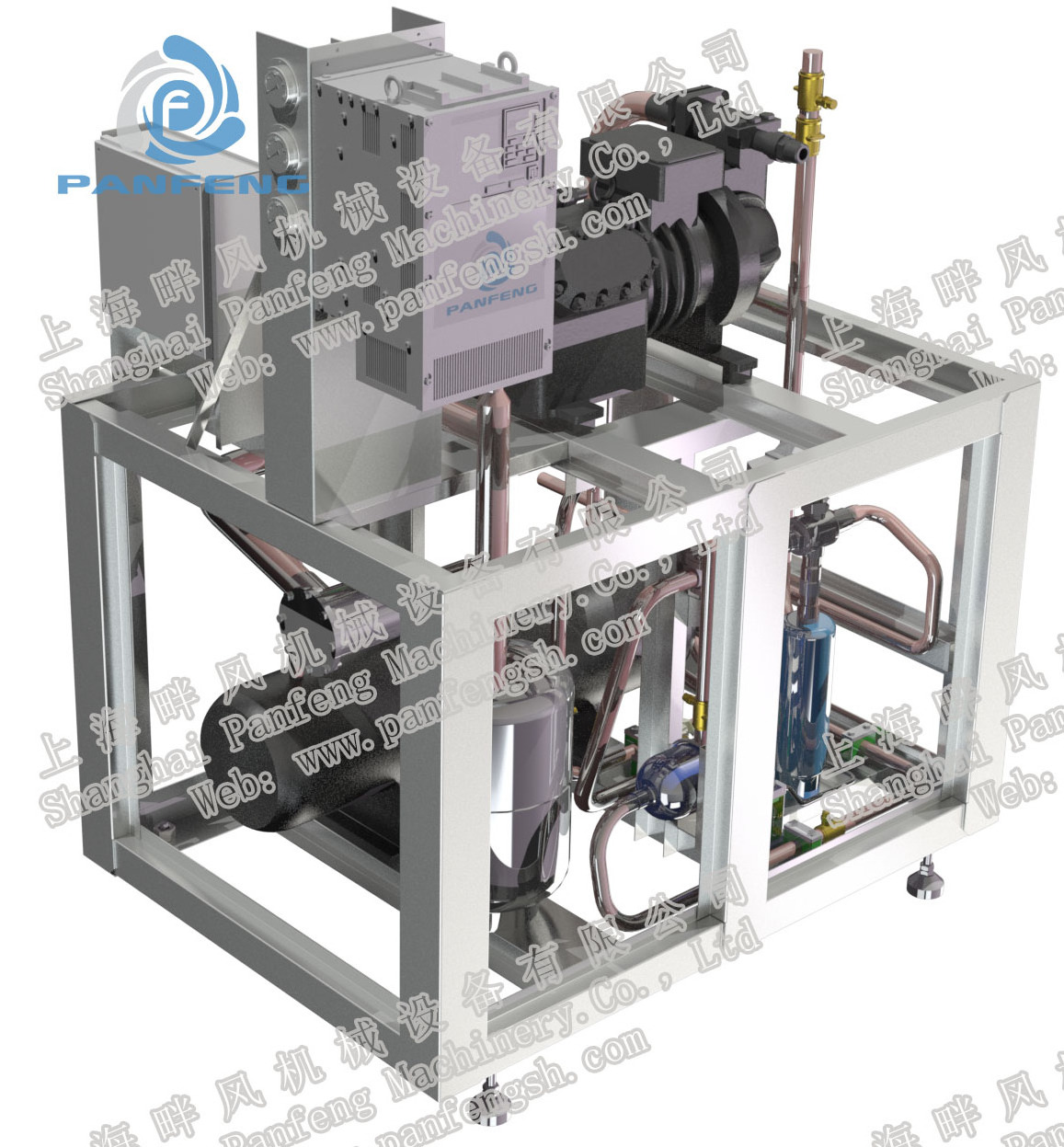

Blast system:

-

low-noise fan

-

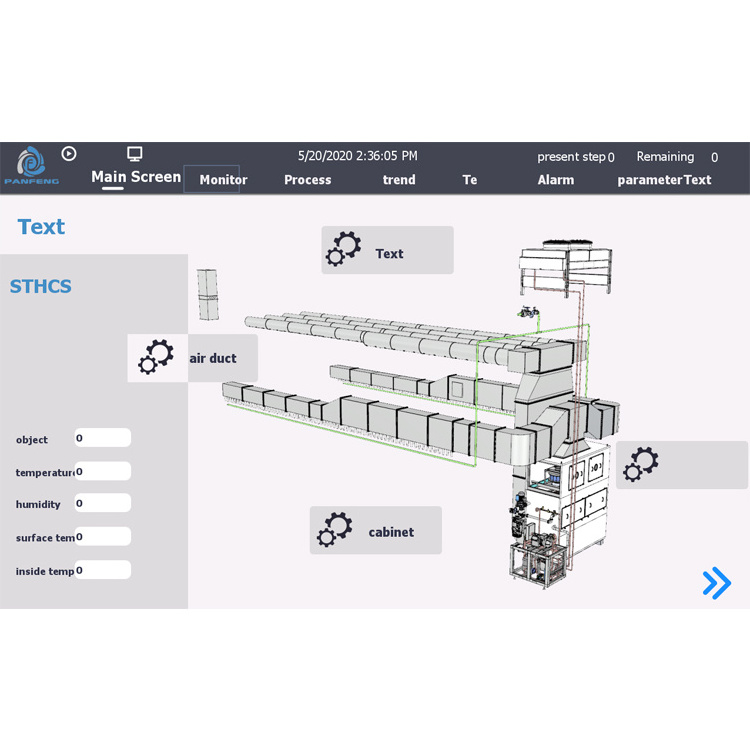

Control system:

-

PID temperature control system

-

Principle:

-

Cooling

-

After Warranty Service:

-

Video Technical Support Online Support

-

After-sales Service Provided:

-

field maintenance and repair service

Quick Details

-

Machinery Capacity:

-

customization

-

Brand Name:

-

Panfeng

-

Year:

-

customization

-

Dimension(L*W*H):

-

customization

-

Weight:

-

1000 KG

-

Place of Origin:

-

China

-

Voltage:

-

customization

-

Key Machines:

-

Fan Filter Unit, HEPA filter, Meat processing plant

-

Product Type:

-

meat, fermented meat, sausage

-

Application:

-

Meat Processing

-

Applicable Industries:

-

Fermented meat

-

Product name:

-

Sausage

-

Function:

-

Make the plant cleaner

-

Temperature:

-

2-40 ℃

-

Blast system:

-

low-noise fan

-

Control system:

-

PID temperature control system

-

Principle:

-

Cooling

-

After Warranty Service:

-

Video Technical Support Online Support

-

After-sales Service Provided:

-

field maintenance and repair service

Definition

Clean Room

room within which the number concentration of airborne particles is controlled and classified, and which is designed constructed and operated in a manner to control the introduction, generation and retention of particles inside the room.

Note 1 to entry: The class of airborne particle concentration is specified.

Note 2 to entry: Levels of other cleanliness attributes such as chemical, viable or nanoscale concentrations in the air, and also surface cleanliness in terms of particle, nanoscale, chemical and viable concentrations might also be specified and controlled.

Note 3 to entry: Other relevant physical parameters might also be controlled as required, e.g. temperature, humidity, pressure, vibration and electrostatic.

Four technical elements of clean room

First, the air supply is filtered at least three times (coarse, medium and high efficiency), and the high efficiency filter should be set at the end of the system.

Second, the clean room should have sufficient purification and air supply volume of air conditioning.

Third, the clean room should maintain the necessary pressure gradient (positive pressure gradient or negative pressure gradient).

Fourth, the clean room should have reasonable air flow organization.

About ISO 14644

ISO-14644 is an international standard and is now used in the United States, Europe, Japan, Russia and China. The original 100, 1000, 10000 and 100000 levels we are familiar with are derived from the US federal standard FS209B, and now they are replaced by the international standard ISO-14644 standard level 5, 6, 7 and 8.

This part of ISO 14644 specifies the classification of air cleanliness in terms of concentration of airborne particles in cleanrooms and clean zones; and separative devices as defined in ISO 14644-7.

Only particle populations having cumulative distributions based on threshold (lower limit) particle sizes ranging from 0.1 μm to 5 μm are considered for classification purposes.

The use of light scattering (discrete) airborne particle counters (LSAPC) is the basis for determination of the concentration of airborne particles, equal to and greater than the specified sizes, at designated

This part of ISO 14644 does not provide for classification of particle populations that are outside the specified lower threshold particle-size range, 0,1 um to 5 um. Concentrations of ultrafine particles (particles smaller than 0.1 μm ) will be addressed in a separate standard to specify air cleanliness by nano-scale particles. An M descriptor may be used to quantify populations of macroparticles (particles larger than 5 μm ).

This part of ISO 14644 cannot be used to characterize the physical, chemical, radiological, viable or other nature of airborne particles.

Classification

Occupancy state(s)

The air cleanliness class by particle concentration of air in a cleanroom or clean zone shall bedefined in one or more of three occupancy states, viz. “as-built," “at-rest" or “operational".

Particle size(s)

One, or more than one, threshold (lower limit) particle sizes situated within the range from20.1um to 25 um are to be used to determine air cleanliness particle concentration forclassification.

ISO Class number/ISO

Air cleanliness class by particle concentration shall be designated by an lSO Class number, N.The maximum permitted concentration of particles for each considered particle size isdetermined from Table 1.

Particle number concentrations for different threshold sizes in Table 1 do not reflect actualoarticle size and number distribution in the air and serve as criteria for classification only.

Table 1 — ISO Classes of air cleanliness by particle concentration

|

ISO Class number (N)

|

Maximum allowable concentrations (particles/m 3 ) for particles equal to and greater than the considered sizes, shown below a |

|

||||||

|

0.1 μm |

0.2 μm |

0.3 μm |

0.5 μm |

1 μm |

5 μm |

|

||

|

ISO Class1 |

10 b |

d |

d |

d |

d |

e |

|

|

|

ISO Class2 |

100 |

24b |

10 b |

4 |

d |

e |

|

|

|

ISO Class3 |

1000 |

237 |

102 |

35 b |

8 |

e |

|

|

|

ISO Class4 |

10000 |

2370 |

1020 |

352 |

83 b |

e |

|

|

|

ISO Class5 |

100000 |

23700 |

10200 |

3520 |

832 |

d,e,f |

|

|

|

ISO Class6 |

1000000 |

237000 |

102000 |

35200 |

8320 |

293 |

|

|

|

ISO Class7 |

c |

c |

c |

352000 |

83200 |

2930 |

|

|

|

ISO Class8 |

c |

c |

c |

3520000 |

832000 |

29300 |

|

|

|

ISO Class9 g |

c |

c |

c |

35200000 |

8320000 |

293000 |

|

|

|

a. All concentrations in the table are cumulative, e.g. for ISO Class 5, the 10 200 particles shown at 0.3μm include all particles equal to and greater than this size. b. These concentrations will lead to large air sample volumes for classification. Sequential sampling procedure may be applied. c. Concentration limits are not applicable in this region of the table due to very high particle concentration. d. Sampling and statistical limitations for particles in low concentrations make classification inappropriate. e. Sample collection limitations for both particles in low concentrations and sizes greater than 1μm make classification at this particle size inappropriate, due to potential particle losses in the sampling system. f. In order to specify this particle size in association with ISO Class 5, the macroparticle descriptor M may be adapted and used in conjunction with at least one other particle size. g. This class is only applicable for the in-operation state. |

|

|||||||

Demonstration of compliance

Principle

Compliance with air cleanliness (ISO Class) requirements specified by the customer is verified by performing specified testing procedures and by providing documentation of the results and conditions of testing.

At-rest or operational classification may be performed periodically based upon risk assessment ofthe application, typically on an annual basis.

For monitoring cleanrooms, clean zones and separative devices, ISO 14644-2:2015 shall be used.

NOTE: Where the installation is equipped with instrumentation for continuous or frequent monitoring of air cleanliness by particle concentration and other parameters of performance as applicable, the time intervals between classification may be extended provided that the results of the monitoring remain within the specified limits.