- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

bosun

-

Model Number:

-

24,30,45,60,80mesh

-

Use:

-

abrasives

-

Product name:

-

95%-97% garnet abrasive powder 80# 120 mesh

-

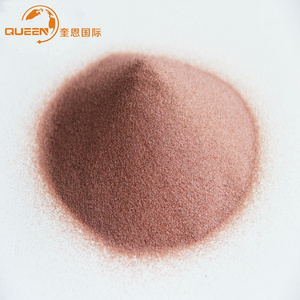

Color:

-

Dark Red

-

Certificate:

-

ISO9001

-

Sample:

-

200g

-

Brand:

-

Bosun garnet abrasive powder

-

Silica:

-

<0.2%

-

Bulk Density:

-

1.96-2.15g/cm3

-

Specific Density:

-

3.98-4.2g/cm3

-

Payment:

-

T/T, 100% L/C at sight

-

MOQ:

-

10 tons

Quick Details

-

Type:

-

blasting media, abrasive

-

Abrasive Grain Sizes:

-

24,30,45,60,80mesh

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

bosun

-

Model Number:

-

24,30,45,60,80mesh

-

Use:

-

abrasives

-

Product name:

-

95%-97% garnet abrasive powder 80# 120 mesh

-

Color:

-

Dark Red

-

Certificate:

-

ISO9001

-

Sample:

-

200g

-

Brand:

-

Bosun garnet abrasive powder

-

Silica:

-

<0.2%

-

Bulk Density:

-

1.96-2.15g/cm3

-

Specific Density:

-

3.98-4.2g/cm3

-

Payment:

-

T/T, 100% L/C at sight

-

MOQ:

-

10 tons

95%-97% garnet abrasive powder 80# 120 mesh

95%-97% garnet abrasive powder 80# 120 mesh

Bosun garnet stones for sandblasting media is a naturally

Bosun garnet stones for sandblasting media is a naturally

inert mineral which have characteristics sharp,angular,and the

hardness 7.5 - 8.0 Mohs scale. The crystal physical properties

make it a superior abrasive, suit for sandblasting machine.

Bosun garnet sand was come from high quality almandine rock

mining.

In order to provide "efficient, economic and environmental"

garnet abrasive,we have 6 steps washing, so it is cleaner for

sandblasting.

Our garnet abrasive media can meet SA2.5 or SA3.0 for the

Description of garnet 80#

|

Colour |

Dark red |

Hardness |

8.0 Mohs |

|

Fracture |

sharp |

Specific Weight |

3.9 g/cm3 |

|

SiO2 |

34-40% |

Melting point |

1300°C |

|

Fe2O3 |

25-31% |

Al2O3 |

17-21% |

|

Ca O |

5.0-10.0% |

Mn O |

0-1.0% |

|

Mg O |

5-6% |

Chloride |

10-15ppm(25ppm max) |

Application/Usage of

abrasive garnet 80#

1)Sand Blasting grade:

20/40,20/60 and 30/60 Fine grains of Abrasive garnet is recommended for blast cleaning application.

Industrial Mineral is a natural Almandine known for its natural hardness, resilience and lends itself to high performance during blasting. Its intrinsic physical and chemical uniformity ensures superior performance.

Garnet is steadily superseding other blasting media because it is environment friendly and reusable

2)Water Filtration:

12/40 Coarser grains are used in a variety of filtration applications which include Industrial Waste Water treatment and commercial water filtration. Garnet is possibly the most cost effective alternativefor water filtration beds as it resets the filter bed more rapidly after the bed is backflushed.Moreover, itis also effective for the elimination of heavy minerals. Furthermore it has the benefit of being chemically inert, recycle in resulting in longer production to Water treatment medium.

3)Water Jet Cutting:

(Coarse 60#, Medium 80# and fine 120# & above 150#, 180#, 200#, 220#)

Micro grains of garnet like Grade #80 / # 120 are perfectly suitable for the Water jet cutting Media

in the Industrial purpose. Uniformity in grain size, hardness, and sturdiness result in cutting-edge

quality, optimum efficiency and low economics. It is perfectly suitable for the applications given below.

Carbon Steel, Stainless Steel, Marble, Ceramics and Road Painting

4)Abrasive Papers:

Abrasive grains are highly useful for coating abrasives, which in turn are used for coating of metal, wood & other coating purposes. Abrasive Paper made out of abrasive grains are mainly used for the surface preparation application for painting and removing of the corrosion particles, which gives new life to surface preparation.

P95%-97% garnet abrasive powder 80# 120 mesh

Packaging details of abrasive garnet

25kg /bag package

40 bags/ Ton bags

18-27 metric tons/ container

We can also pack the garnet abrasive powder according to customer's requirement.

Delivery details of abrasive garnet

7 days after receiving the advance payment

Media Selection Guide

| Glass Beads | Ceramic Beads | Cut Wire | Steel Shot | Steel Grit | Aluminum Oxide | Silicon Carbide | Garnet | Crushed Glass | Plastic | Sand | |

| Finishing | yes | yes | yes | yes | yes | yes | yes | yes | yes | yes | yes |

| Cleaning/Removal | yes | yes | yes | yes | yes | yes | yes | yes | yes | yes | yes |

| Peening | yes | yes | yes | yes | no | no | no | no | no | no | no |

| Surface Profiling | no | no | yes | no | yes | yes | yes | yes | yes | yes | yes |

| Work Speed | med | med | med | med | med-high | high | very high | high | high | med-high | low |

| Recyclability | med | high | high | very high | very high | med-high | med-low | med | med-low | med | low |

| Probability of metal removal | very low | very low | very low | very low | med | med-high | med-high | med | low-med | very low | med-high |

| Hardness MOH Scale | 5.5 | 7 | 6-7.5 | 6-7.5 | 8-9 | 8-9 | 9 | 8 | 5.5 | 3-4 | 5-6 |

| Bulk Density (lb/cu. Ft) | 100 | 150 | 280 | 280 | 230 | 125 | 95 | 130 | 100 | 45-60 | 100 |

| Mesh Size | 30-440 | 8-46 | 20-62 | 8-200 | 10-325 | 12-325 | 36-220 | 16-325 | 30-400 | 12-80 | |

| Typical Blast Pressure | 20-55 | 20-90 | 20-90 | 20-90 | 20-90 | 20-90 | 20-90 | 30-80 | 20-50 | 20-60 | 80-100 |

Quality standard

Our products meet national standards and Industry standards, the company production, testing the light of international and national standards include the following standards.

1. Preparation of steel substrates befor application of paints and related products-Specifications for metallic blast-cleaning abrasives-?

Part 3: High-carbon cast-steel shot and grit (GB/T 18838.3-2008)

2. Preparation of steel substrates befor application of paints and related products-Specifications for metallic blast-cleaning abrasives-?

Part 4:Low-carbon cast-steel shot (GB/T 18838.4-2008)

3. Preparation of steel substrates befor application of paints and related products-Specifications for non-metallic blast-cleaning abrasives- ( GB/T 17850—2002)

4. Metal-Inspection method of mircostructure (GB/T 13298-91)

5. Metallic materials-Vickers hardness test (GB 4340-1999)

6. Preparation of steel substrates befor application of paints and related products-Test methods for metallic blast-cleaning abrasives- (GB/T 19816-2005)

7. Preparation of steel substrates befor application of paints and related products-Test methods for non-metallic blast-cleaning abrasives- (GB/T 17849-1999)

Quality control

The test center of the company has perfect quality testing methods, has carbon-sulfur analyzer, arc burning furnace, elemental analyzer, metallographic micro-hardness tester and other quality control equipment at present, can check composition, hardness and service life and the like of the products, and ensures that products meet the national standards or the requirements of purchasers.

Inspection equipment