The final particle size is determined by temperature and time.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2000*1300*1800

-

Product name:

-

Plastic Recycling Granulator Machine

-

Application:

-

Waste Plastic Recycling

-

Process Type:

-

Agglomerate

-

Motor:

-

SIEMENS Brand

-

Temperature controller:

-

Omron

-

Max. Capacity::

-

100-800kg/h

-

After-sales Service Provided::

-

Overseas service center available

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

VINA

-

Weight (KG):

-

2300

-

Dimension(L*W*H):

-

2000*1300*1800

-

Product name:

-

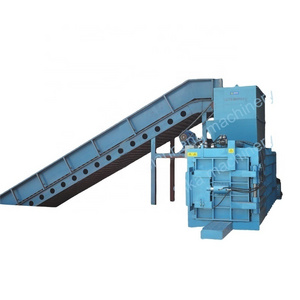

Plastic Recycling Granulator Machine

-

Application:

-

Waste Plastic Recycling

-

Process Type:

-

Agglomerate

-

Motor:

-

SIEMENS Brand

-

Temperature controller:

-

Omron

-

Max. Capacity::

-

100-800kg/h

-

After-sales Service Provided::

-

Overseas service center available

Product Description

Features

Agglomerator, can be also called Granule Making Machine, is mainly applicable for film or fiber recycling.blade can be disassembly.

The particles can be used for extrusion or injection mould machine directly. Also it can be further pelletized for some advanced requirements.

GHX agglomerator can directly make waste plastic films and PET chips and PET/PP fiber and some other textile products into granules. It is suitable to agglomerate the waste products or films made of soft PVC, PET, HDPE, LDPE, PP and other thermo plastics. When the waste plastic is supplied into the chamber of such machine, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife. During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the material will be going to become semi-plasticizing state. The

particles will stick with each other due to the function of plasticization. Before it sticks each other completely, the cold water pre-prepared is sprayed into the crushed material. The water will be evaporated off quickly and the surface temperature of crushed material drops down quickly. So the crushed material will become small particles or granules. It is easy to recognize the particles by different size and can

be colored by using of color agent being putted into the container during the crushing processing.

particles will stick with each other due to the function of plasticization. Before it sticks each other completely, the cold water pre-prepared is sprayed into the crushed material. The water will be evaporated off quickly and the surface temperature of crushed material drops down quickly. So the crushed material will become small particles or granules. It is easy to recognize the particles by different size and can

be colored by using of color agent being putted into the container during the crushing processing.

|

MODEL

|

GSL-100

|

GSL-200

|

GSL-300

|

GSL-500

|

GSL-600

|

GSL-800

|

|||||

|

Vloumn (L)

|

100

|

200

|

300

|

500

|

600

|

800

|

|||||

|

Effective Volumn (L)

|

75

|

150

|

225

|

375

|

450

|

620

|

|||||

|

Power (kw)

|

37or45

|

45

|

75

|

90 or 110

|

110 or 132

|

110 or 160

|

|||||

|

Capacity (kg/h)

|

80-120

|

100-180

|

180-240

|

250-320

|

350-400

|

450-600

|

|||||

|

Moving blade(pcs)

|

2

|

2

|

2

|

4

|

4

|

4

|

|||||

|

Fixed blade(pcs)

|

6

|

6

|

8

|

8

|

8

|

8

|

|||||

|

Blade Material

|

SKD-11 or 9CrSi or T-10(Has toughness and is not prone to fracture)

|

|

|

|

|

|

|||||

|

Material of barrel

|

Stainless steel

|

|

|

|

|

|

|||||

Detailed Images

Barrel bottom :

Precision processing, 304 stainless .steel material, 8mm thickness.

Blade fixing base :

The blade and base are both Dynamic equilibrium to extend the service life of the bearing.

Electrical equipment :

.

Independent electrical cabinet.

Siemens or Schneider contact.

Blade :

Rotating and fixed blades,

SKD-11 or

other

material, wear-resistant.

The number of blades varies depending on the device model.

Application

Application Material

.

It is suitable to agglomerate the waste products or films made of soft PVC, PET, HDPE, LDPE, PP and other thermo plastics.

Finish product

Hot Searches