- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/3Ph/50Hz

-

Dimension(L*W*H):

-

2150*780*1740mm

-

Weight:

-

1300 kg

-

Marketing Type:

-

Hot Product 2023

-

Model:

-

SZLH320

-

Product:

-

feed pellet mill machine

-

Main power:

-

37kw

-

ring die diameter:

-

350mm

-

roller quantity:

-

2pcs

-

product capacity:

-

1-3tons/h

-

pellet diameter:

-

1.5mm-12mm

-

packing:

-

one set packing into plywood case

-

Application:

-

Producing Animal Feeds Pellets

-

After-sales Service Provided:

-

Online Support

Quick Details

-

Max. Capacity:

-

1-3 ton/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Double Crane

-

Voltage:

-

380V/3Ph/50Hz

-

Dimension(L*W*H):

-

2150*780*1740mm

-

Weight:

-

1300 kg

-

Marketing Type:

-

Hot Product 2023

-

Model:

-

SZLH320

-

Product:

-

feed pellet mill machine

-

Main power:

-

37kw

-

ring die diameter:

-

350mm

-

roller quantity:

-

2pcs

-

product capacity:

-

1-3tons/h

-

pellet diameter:

-

1.5mm-12mm

-

packing:

-

one set packing into plywood case

-

Application:

-

Producing Animal Feeds Pellets

-

After-sales Service Provided:

-

Online Support

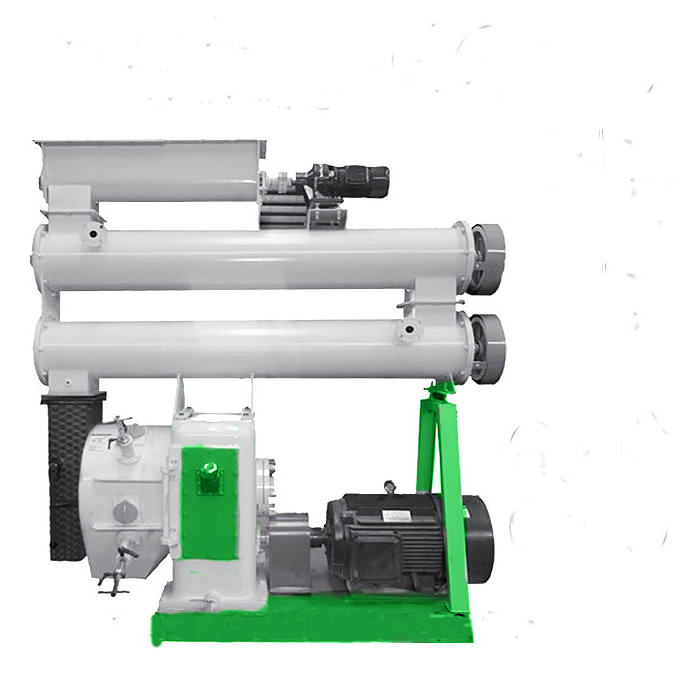

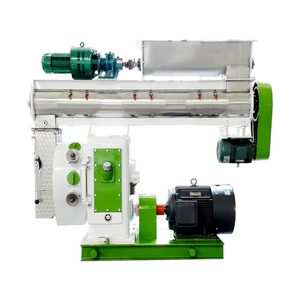

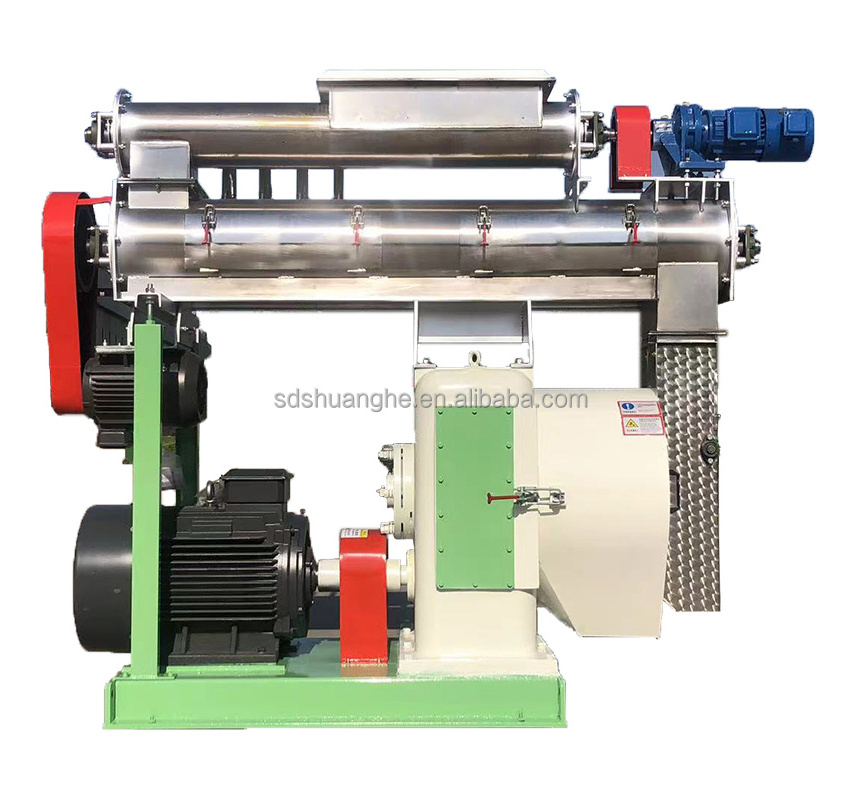

Animal Feed Pellet Making Ring Die Pellet Machine Pellet Mill Feed Pellet Machine for Sale

1. Ring Die Poultry Feed Pellet Making Machine Brief Specification:

1.1 The ring die feed pellet machine is widely used in large, medium and small-scale feed pellet plant.

2.1 Powder feed meal without or little water can be granulated, so the feed pellet is easier to store.

2.3 The ring die feed pellet machine simple structure, wide adaptability, small footprint, low noise.

2.4 The ring die feed pellet machine can very good to keep all kinds of trace elements in raw materials, good palatability, animal feed intake, conducive to digestion and absorption.

2.5 The ring die feed pellet machine processing of the material and the appearance is neat, smooth surface, density is big, easy to store and transport.

2. Ring Die Poultry Feed Pellet Making Machine Advantege:

2.1 Steam conditioner make aging treatment on powder feed material.The ability of most animal digestion of starch is very low, but easy digestion of cooked starch, conditioning device to make the feed material under the action of heat and hot water, starch gelatinization degree increased significantly, but also promote the material thermal denaturation of protein, denaturation of protein by enzymatic hydrolysis easily, thus improves the digestion of pellet feed utilization rate.

2.2 Steam conditioner for sterilization processing powder material.Most harmful pathogenic bacteria such as e. coli and salmonella bacteria, not heat-resisting, the conditioning device for material under a certain temperature conditioning can kill the bacteria, guaranteed to feed hygiene standards, through the conditioning device for material sterilization method compared with drug prevention, has the advantage of low cost, no pollution, no drug residues and side effects, etc.

2.3 Steam conditioning equipment can significantly improve the pellet feed water resistance, in the process of quenched and tempered by through the role of the heat and water vapor, viscosity of the material components manufacture gelatinized starch, modified protein can give full play to the adhesive for bonding around other components effectively, in pressure die roll extrusion With the particles and particle together more closely, to make it more dense granule feedstuff, appearance is bright and clean, not in the process of breeding Vulnerable to water erosion and increase the stability of the water.

2.4 Steam conditioning equipment can improve the material granulating, increase production capacity, save the energy consumption of the granulating, improve the use life time of pelletizer ring die and roller.

By steam conditioning, feed material softening, more flexible, on the inner wall of the ring die, die and roller appearance of extrusion process, the friction force is reduced,Avoided in the granulating process a large amount of mechanical energy into heat energy, and slows down the ring die and roller wear and tear.

3. Data Sheet for Poultry Feed Pellet Making Machine :

|

Items |

HKJ250 |

SZLH300 |

SZLH320 |

SZLH350 |

SZLH420 |

SZLH508 |

|

Product capacity(t/h) |

0.8-1.5 |

1.5-2.5 |

2.0-4.0 |

3.0-6.0 |

3.0-12.0 |

4.0-15.0 |

|

Main power(kW) |

22 |

30 |

37 |

55 |

110 |

132 |

|

Feeder power(kW) |

0.75 |

0.75 |

0.75 |

0.75 |

1.5 |

1.5 |

|

Conditioner power(kW) |

2.2 |

2.2 |

2.2 |

2.2 |

5.5 |

7.5 |

|

Inside diameter(mm) |

250 |

300 |

320 |

350 |

420 |

508 |

|

Roller quantity(pcs) |

2 |

2 |

2 |

2 |

2 |

2 |

|

Feeder speed(rpm) |

20-120rpm |

|||||

|

Conditioner Speed (rpm) |

360 rpm |

|||||

|

Feed pellet diameter(mm) |

φ 1.5, φ 2, φ 2.5, φ 3, φ 3.5, φ 4, φ 4.5, φ 5, φ 6, φ 8, φ 10, φ 1 2 |

|||||

|

Pellet shaping rate |

≥ 95% |

|||||

|

Steam Pressure |

0.1-0.4Mpa |

|||||

|

Steam Consumption |

≥0.1-0.3 |

|||||

|

Steam Temperature (℃) |

130-150°C |

|||||

|

Pellet mill noise (dB) |

≤86dB(A) |

|||||

|

Application |

Use to produce feed pellet for fish/poultry/chicken/rabbit/sheep/cattle |

|||||

The Photos of Ring die Poultry Feed Pellet Making Machine :

Feed Pellet Raw Material Can Be Grain Or Straw:

Finished pellet:

Pellet Application:

1. For single machine, it will cover plastic film and then packing into a plywood case.

2. If by Container, the machine with plastic film will loading into container and then fixed. If you have special request,we will also pack machine as your request.