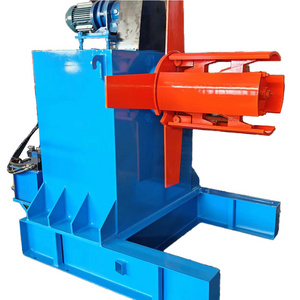

The automatic hydraulic expanding and shrinking uncoiler can support 5T steel coils, expand and shrink, and drive the steel coils to rotate at the same time.

Three arms expanding device with sliding block can provide more powerful force to fixing the coil, The synchronous action can avoid the deformation of the coil.The block installed on the the arms can suit the coils with bigger inner diameter.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ three phase,customized

-

Power:

-

5KW

-

Dimension(L*W*H):

-

4200*1200*1500mm

-

Weight (KG):

-

3000

-

Product name:

-

Decoiler Straightener Feeder Machine

-

Application:

-

Steel Coil Decoiler

-

material:

-

Metal Steel Sheet

-

Max coil width:

-

1200mm

-

Steel coil inner:

-

470-550mm

-

Straightening:

-

30-40m/min

-

Feeder:

-

Automatic Feeding System

-

Thickness of material:

-

0-2mm

-

Machine Type:

-

CNC Automatic

-

Keyword:

-

Uncoiling Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

New Product

-

Brand Name:

-

Hokang

-

Voltage:

-

380V 50HZ three phase,customized

-

Power:

-

5KW

-

Dimension(L*W*H):

-

4200*1200*1500mm

-

Weight (KG):

-

3000

-

Product name:

-

Decoiler Straightener Feeder Machine

-

Application:

-

Steel Coil Decoiler

-

material:

-

Metal Steel Sheet

-

Max coil width:

-

1200mm

-

Steel coil inner:

-

470-550mm

-

Straightening:

-

30-40m/min

-

Feeder:

-

Automatic Feeding System

-

Thickness of material:

-

0-2mm

-

Machine Type:

-

CNC Automatic

-

Keyword:

-

Uncoiling Machine

Products Overview

3 Tons 5t 10 Ton Hydraulic Decoiler with Coil Car Full-Automatic Metal Sheets Decoiler

We are involved in manufacturing and export a comprehensive range of decoilers and uncoilers. Fabricated as per set industrial standards, our range of available in both motorized and non-motorized form. Stringently checked on quality parameters, these are available in various capacities and specifications to meet variegated demands of clients.

Hydraulic decoiler for the metal slitting line is designed to match lots of heavy duty metal processing tools. For the hydraulic decoiler we design with 5 ton, 7 ton, 8 ton, 10 ton, 25 ton and even to 30 ton double head decoiler. We can design hydraulic decoiler according to your requirements.

Hydraulic decoiler for the metal slitting line is designed to match lots of heavy duty metal processing tools. For the hydraulic decoiler we design with 5 ton, 7 ton, 8 ton, 10 ton, 25 ton and even to 30 ton double head decoiler. We can design hydraulic decoiler according to your requirements.

Specification

|

item

|

value

|

|

Product name

|

Hydraulic uncoiler

|

|

Brand Name

|

HOKANG

|

|

Voltage

|

380V 50HZ three phase,customized

|

|

Power

|

5KW

|

|

Dimension(L*W*H)

|

4200*1200*1500mm

|

|

Weight (KG)

|

3000

|

|

Application

|

Steel Coil Decoiler

|

|

Max.coil width

|

1200mm

|

|

Steel coil inner

|

470-550mm

|

|

Straightening

|

30-40m/min

|

|

Feeder

|

Automatic Feeding System

|

|

Thickness of material

|

0-2mm

|

|

Machine Type

|

CNC Automatic

|

Details Images

Support Arm Of Hydraulic Decoiler

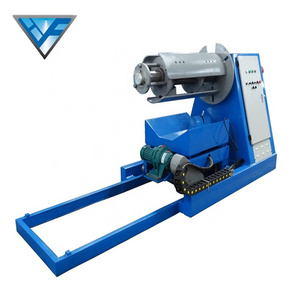

Feed Car Of Hydraulic Decoiler

The feeding trolley can move forward and backward, and lift up and down. The steel coil is placed on the support arm through the feeding trolley, thus realizing automation, simple operation and labor saving.

Full automatic hydraulic uncoiler supports customization of various widths and weights. For more information, please contact us.

Full automatic hydraulic uncoiler supports customization of various widths and weights. For more information, please contact us.

Control System Of Hydraulic Decoiler

The hydraulic uncoiler is in both Chinese and English, with multiple color buttons, which is easy to identify and identify products, simple to operate, and low technical requirements.

The company has a variety of types of uncoilers, manual, electric, hydraulic, support color and logo customization.

The company has a variety of types of uncoilers, manual, electric, hydraulic, support color and logo customization.

This auto uncoiler is used to support the coil for roll forming machine

1. Automatic uncoiler is an auxiliary equipment for roll forming machine.it is composed of feed main machine, hydraulic station and control system.

When it works together with roll forming machine and auto stacker, they make up a completely steel panel production line.

2. The working process is loading coil→expanding to fix the coil→uncoiling→feeding the sheet into roll forming machine.

3.The advantage for automatic uncoiler is, highly automatic, high producing efficiency, and low labor cost.

There is a sensor, to keep uncoiler goes at the same speed as roll forming machine.

When it works together with roll forming machine and auto stacker, they make up a completely steel panel production line.

2. The working process is loading coil→expanding to fix the coil→uncoiling→feeding the sheet into roll forming machine.

3.The advantage for automatic uncoiler is, highly automatic, high producing efficiency, and low labor cost.

There is a sensor, to keep uncoiler goes at the same speed as roll forming machine.

Our Service:

Terms of Payment:

30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid.by T/T after inspection by buyer in seller's factory while before delivery.

Delivery: 30 days after receipt of advance payment.

Service: we send technician to your country to fix the machine.The buyer should bear all the cost including: visa, Round trip tickets and suitable accommodation, also buyer should pay salary 80USD/day.

Warranty: 12 months limited warranty.

During warranty: parts are free but buyer pay for the shipping fee.

Delivery: 30 days after receipt of advance payment.

Service: we send technician to your country to fix the machine.The buyer should bear all the cost including: visa, Round trip tickets and suitable accommodation, also buyer should pay salary 80USD/day.

Warranty: 12 months limited warranty.

During warranty: parts are free but buyer pay for the shipping fee.

Hot Searches