- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FM450

-

Accuracy:

-

±2%, ±2℃td dew point

-

Temperature range:

-

-100~20

-

Power supply:

-

Rated 24VDC (8 ~ 36V DC)

-

Current loop:

-

4 --- 20MA two-wire system

-

Measuring range:

-

-110 ℃ --- +20 ℃ td

-

Product name:

-

Super quality temperature humidity portable dew point meter

Quick Details

-

Theory:

-

Hygrometer

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

MESSTECHNIK

-

Model Number:

-

FM450

-

Accuracy:

-

±2%, ±2℃td dew point

-

Temperature range:

-

-100~20

-

Power supply:

-

Rated 24VDC (8 ~ 36V DC)

-

Current loop:

-

4 --- 20MA two-wire system

-

Measuring range:

-

-110 ℃ --- +20 ℃ td

-

Product name:

-

Super quality temperature humidity portable dew point meter

4-20 mA Digital psychrometer transmitter humidity and temperature dew point meter

|

Product Name |

Dew point Transmitter |

|

Item NO. |

Fm450 |

|

Product parameters |

|

|

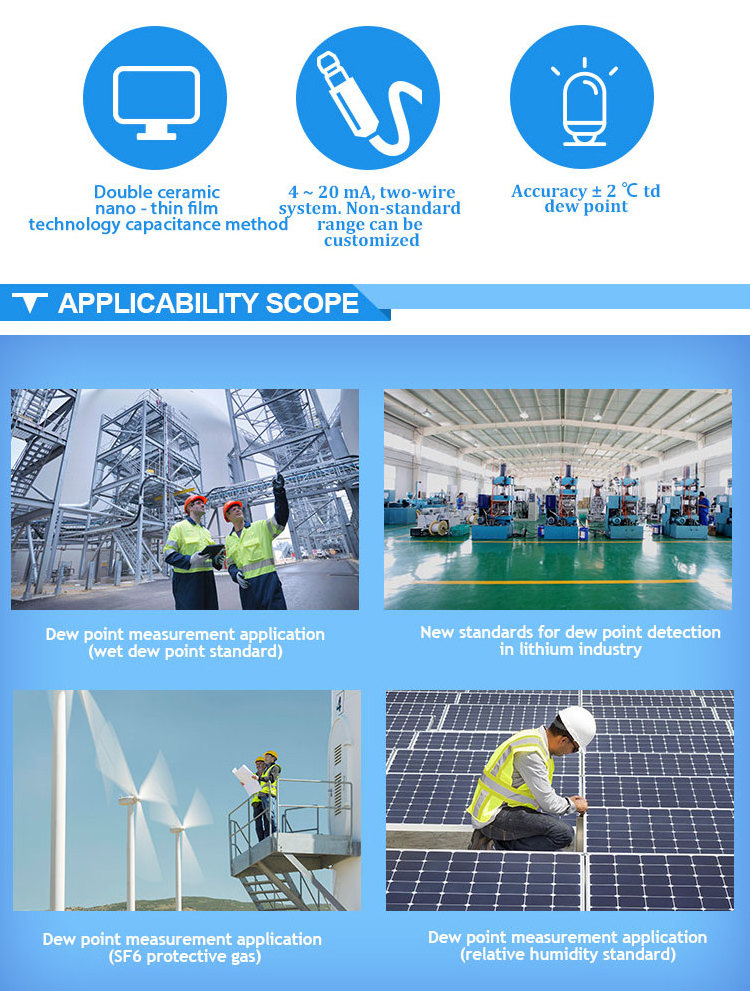

Sensing element |

dual ceramic nanometer thin film technology capacitance method) |

|

Power supply |

Rated 24VDC (8 ~ 36V DC) |

|

Current loop |

4 --- 20MA two-wire system |

|

Measuring range |

-110 ℃ --- +20 ℃ td |

|

Accuracy |

±2℃td dew point |

|

Repetition rate |

±0.5℃td dew point |

|

Resolution |

0.1 ℃ dew point |

|

Response time |

T95 about 1 minute (from dry to wet) |

|

Working pressure |

40MPa |

|

Rated operating temperature |

-40 ℃ ~ +60 ℃ |

|

Operating humidity |

0 ~ 100% RH |

|

Rated protection |

IP65 |

|

Flow range |

0.2 to 5 liters / min 0 to 10 m / s |

|

Filter |

20μ stainless steel sintered |

|

Weight |

170g |

|

Fault condition |

|

|

Fault |

23mA (or 3.5mA, can be set) |

|

Dew point range below the lowest point |

4mA |

|

Dew point range above the maximum |

20mA |

Zunkin Technology is committed to providing full range of automation control products, integrated solutions and technical services, anti-static security control.

Our main agent of the United States AMCELLS, Germany HBM, Japan YAMATO, Japan NTS, South Korea DACELL, Dr.Storage and other companies, is a Chinese mainland dealers.

Main products as like Load cell, pressure sensor, Pull pressure sensor, Torque Sensor, Dew point meter,displacement transducer, weigher , Dry Cabinet, Ionizers , ESD Magazine Racks, cleanroom so on .

( 1) What is dew point temperature (Td)?

Characterization of the degree of dryness of the humidity unit, refers to the air in the water vapor saturated water began to condense the temperature, that is, when the temperature of condensation. At 100% relative humidity, the ambient temperature is equal to the dew point temperature. The smaller the dew point temperature to the ambient temperature, condensation may mean smaller, which means more dry air.Dew point not affected by temperature, but by the pressure.

(2)Drying method for compressed air?

In order to solve the problems caused by excessive moisture, a variety of principles of drying equipment came into being, and was used for air pressure.

Machine equipment supporting. There are two basic compressed air dryers: a freeze dryer and an adsorption dryer.

Frozen dryers are often used to remove excess moisture from compressed air. It is through the use of refrigeration systems and different.

Of the heat exchanger to reduce the compressed air temperature to +2 ... +5C, (air dew point temperature), then the air too much water is condensed after the exclusion, after the gas is heated back to room temperature. The freeze dryer is controlled by measuring the freezing temperature, but it is usually necessary to measure the dew point to ensure that the dryer is working properly.

The adsorption dryer dries the moisture through the desiccant to dry the gas. The most commonly used desiccant is silica gel, activated alumina, molecular sieves. Adsorption drying method is usually higher than the freeze-drying efficiency, adsorption drying method can be dry to 40 ° C dew point temperature, if the molecular sieve and silica gel or activated alumina can be used in conjunction with -100.C dew point temperature. The adsorption dryer usually consists of two drying towers filled with desiccant and through the valve to control the flow of compressed air in both drying towers. The drying process and the regeneration process are carried out. During the drying process, the compressed air flows from a drying tower under pressure, and when the gas flows through the desiccant, the microvoids on the surface of the desiccant adsorb the moisture in the air. For the regeneration of desiccant, usually a variety of design, usually by heating the desiccant in the absorption of water to remove, to restore water absorption capacity.

(3) Dew point measurement can save energy better.

According to statistics, the factory about 10% of the energy consumption is used to produce compressed air reliable dew point measurement can accurately control whether the dryer is working within the technical indicators. For desiccant desiccators, the regeneration interval can be controlled by measuring the dew point and saving a lot of energy for the user. Unlike conventional timer methods, the system does not start the regeneration function as long as the degree of compressed air is within the range required by the user. Dew point control can be for the user.Saving up to 80% of the energy costs.

(4) How does water in compressed air form?

As the compressor compresses the air, the dew point of the compressed gas rises, and at some point the moisture in the gas reaches saturation and begins to condense. For example, a 30-kilowatt compressor can produce about 20 liters of liquid water at 8 hours of operating time when compressing air at 20.C, 60% RH.

(5) What is the generation of compressed air?

The air compressor to do the mechanical movement to reduce the size of the air after the pressure is called compressed air. Compressed air is an important power source, with: pollution-free, clear and transparent, easy to transport, no harmful performance, no fire risk, etc., therefore, is widely used in all aspects of production enterprises. For example, the operation of the processing machinery, the transmission and control of the pneumatic valve, the cylinder and the controller, the transmission medium or the purge gas. In order to obtain dry, clean, oil-free, meet the requirements of clean compressed air, it must be purified. The filtration system can remove the oil and dust, and the water is dehydrated by the dryer.