- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

60*1.4*4.5m, 50*2*2.3m

-

Weight:

-

3000

-

Power (kW):

-

18kw

-

Product name:

-

condom making machine

-

Color:

-

Customers' Demand

-

Feature:

-

Fully Automatic

-

Output:

-

300000/day

-

Power:

-

50KW/h

-

Lenght:

-

30m

-

Key words:

-

Condom Dipping Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Voltage:

-

380V or customize

-

Dimension(L*W*H):

-

60*1.4*4.5m, 50*2*2.3m

-

Weight:

-

3000

-

Power (kW):

-

18kw

-

Product name:

-

condom making machine

-

Color:

-

Customers' Demand

-

Feature:

-

Fully Automatic

-

Output:

-

300000/day

-

Power:

-

50KW/h

-

Lenght:

-

30m

-

Key words:

-

Condom Dipping Machine

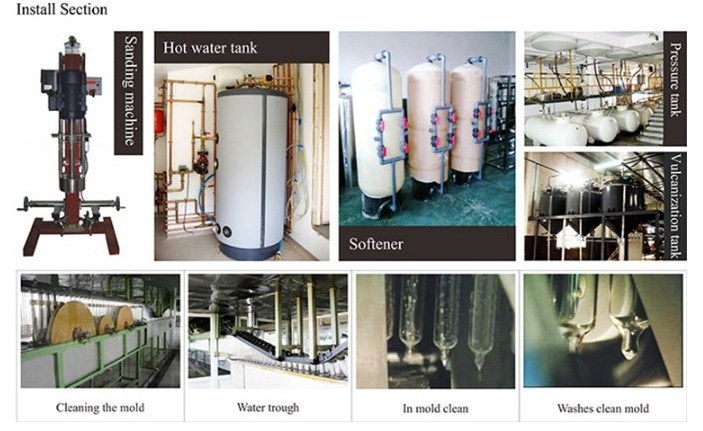

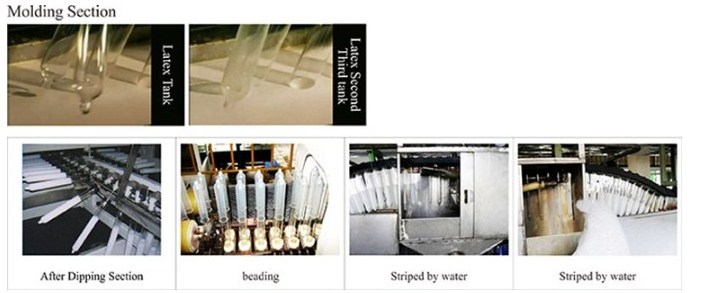

1. Adopting advanced three-step impregnation process technology, advanced process layout and diversified process production adjustment.

2. The ammonia water swelling process is cancelled and the longer alkali water tank design is changed to achieve the effect of swelling and leaching, which is environmentally friendly and saves.

3. The template is made of 304 stainless steel, the whole chain is driven by three hosts, and the frequency conversion speed control is used, and the equipment runs smoothly.

4. The whole machine is suspended from stainless steel plate and sealed by plastic steel.

5. The equipment has been fully, effectively and reliably designed to prevent head bubbles, backflow, crooked necks, curling, pinholes, etc.

6. It can produce all kinds of ordinary and special-shaped condoms such as smooth, granular, threaded, and colorful condoms.

7. All rubber materials used in production are pressure conveyed by fully enclosed stainless steel pipelines.

8. The energy-saving design of the film drying structure, which consumes 19.5kg of standard coal per 10,000 condoms.

9. De-filming with clean water and continuous pickling to fully ensure the cleanliness of molds and equipment.

10. Mix powder on the machine, dehydrate, and directly dry after vulcanization, making the production operation more energy-saving and simpler.

| Production line dimensions | length 65m×width 3m×height 4.5m |

| Main engine drive | 2.2KW×3 sets |

| Heat energy consumption | 1T/h |

| Power consumption | 70KW |

| Water consumption | 6T/h |

| Chain length of production line | 215 meters |

| Mold spacing | 80mm |