- Product Details

- {{item.text}}

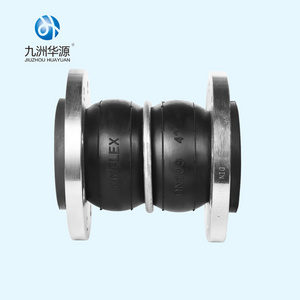

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Liwei

-

Model Number:

-

GJQ(X)-DF

-

Diameter:

-

DN300

-

Length:

-

245mm

-

Working pressure:

-

10 bar

-

Rubber:

-

EPDM or other rubber material

-

Flange:

-

Carbon steel

-

Treatment:

-

Galvanized

-

Application:

-

oil,water,acid,alkali,sea water,coal slurry

-

Flange drilling:

-

BS4504

Quick Details

-

Technics:

-

Forged

-

Shape:

-

Equal

-

Head Code:

-

Hexagon

-

Place of Origin:

-

China

-

Brand Name:

-

Liwei

-

Model Number:

-

GJQ(X)-DF

-

Diameter:

-

DN300

-

Length:

-

245mm

-

Working pressure:

-

10 bar

-

Rubber:

-

EPDM or other rubber material

-

Flange:

-

Carbon steel

-

Treatment:

-

Galvanized

-

Application:

-

oil,water,acid,alkali,sea water,coal slurry

-

Flange drilling:

-

BS4504

Rubber flexible joint is also called: flexible rubber expansion joint, rubber soft connection, and soft rubber joint, rubber compensator, rubber shock hose, rubber shock reducer, is one kind of high elasticity, high air tightness, medium resistance and weather ability pipe fittings.

Rubber flexible joint consists of outer rubber, inner rubber, framework layer, and reinforcing bar and flange. Relying on rubber’s special performances as long range elasticity, air impermeability, medium, climate and radiation resistance, rubber expansion couplings can reduce the vibration and noise of pipeline, and can be caused by the temperature change of heat bilges cold shrink compensation effect.

Characteristic Feature:

(1)Small volume, light in weight, very good flexibility, Convenience installation and maintenance.

(2)Transverse displacement, axial displacement, angular displacement

(3)Reduce noise, shock absorption

Range of application:

Due to favorable integrated performance, they can be widely used in chemical industry, Construction, water supply, drainage, oil industry, light and heavy industry, refrigeration station, water heating system, fire fighting system, electric power system, etc.

Structure:

Rubber flexible joint manufacturing progress

1. Raw material: we never use reclaimed raw rubber, rubber is imported from USA. Before used, raw material should be tested, including physical test and some chemical experiment to test the hardness and so on;

2. Rubber pretreating and ingredients;

3. Milling: first, rubber plastication, second, rubber mixing, we will add rubber compounds, like sulfurzing reagent, surfactant, softener, stabilizer, foaming agent and some special compounds, at the same time, rubber will be extruded into plates, cut, produce 45 degree angle. The plates cannot directly be used, they should be cooled about 24 hours;

4. Molding: it will cost much time;

5. Vulcanizing: the largest vulcanizing tank in Asia ø5000*15000, right time, temperature, pressure is very important;

6.Test and experiment: these tests should be done, hydraulic test, resistance to vacuum, displacement of the performance, rubber physical properties, thickness and the strength and other quality test;

7. Package: out package the free of fumigation wooden case; inside package: plastic film and textile membrane.

Rubber Mixing and cord fabric cloth manufacturing

Cord fabric cloth cutting, the angular must be 45 degree

Rubber bellow early moulding

Rubber vulcanization

Rubber bellow thickness tests

Pressure tests: hydraulic, 1.5 times of working pressure, at least 20 minutes

Flange manufacturing

Rubber flexible joint for PVC pipe package

Outside:usually, the package is outside non fumigation wooden case, if the size is too large, the package will be steel frame.

Inside: wooven cloth, if the diameter is less than 250mm, the inside can be carton box.

Liwei gate

Office Building

Overview

Rubber lining workshop

Rubber flexible joint manufacturing workshop

Cold machining workshop

Metal workshop

Tests Workshop

Warehouse

Liwei family .

Liwei rubber flexible joint advantage

1. We have our factory and about 200 workers.

2. Our company established in 1988, 30 years experience.

3. The largest diameter DN3600.

4. Our rubber flexible joint has been used for 20 years and still under operation in Shanghai.

5. We keep cooperation with 90% of Chinese power plants

6. Hydraulic pressure tests and burst pressure tests can be made.

7. The largest vulcanizing tank in Asia:5000mm*15000mm

8. The member of CNEA(China Nuclear Energy Association)

9. ISO9001:2008 and ISO14001:2004 certificate by CNAS(China National Accreditation Service Conformity Assessment)

10. We can export by us, without trading company.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.