2. During installation, adjust the height of the slider of the press according to the closing height of the mold so that the slider is at the bottom dead center at a specified position between the bottom surface and the work surface. , Make the mold handle enter the mold handle hole, and fix the mold handle by the pressing block and screw on the slider. 3.After installation, raise the slide of the press by 3-5㎜, start the press, stop the slide at the bottom dead center 1-2 times, and fix the lower mold base. Perform another test punch and gradually adjust the height required by the slider. Adjust the discharge plate on the press to the required position.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

V635J

-

Name:

-

tooling plastic injection mold manufacturer

-

Feature:

-

OEM/ODM, 10 years experiences on pen mold

-

Delivery Time:

-

15 Days

-

Port:

-

GuangZhou or ShenZhen

-

MOQ:

-

1Set

-

Hardness:

-

HRC42-60

-

Packing:

-

Plastic or bubble bag pack

-

Surface finish:

-

Polish/Mirrow/Matte

-

Usage:

-

Injection machine

-

Shipping way:

-

DHL,UPS,Fedex

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Vertical

-

Model Number:

-

V635J

-

Name:

-

tooling plastic injection mold manufacturer

-

Feature:

-

OEM/ODM, 10 years experiences on pen mold

-

Delivery Time:

-

15 Days

-

Port:

-

GuangZhou or ShenZhen

-

MOQ:

-

1Set

-

Hardness:

-

HRC42-60

-

Packing:

-

Plastic or bubble bag pack

-

Surface finish:

-

Polish/Mirrow/Matte

-

Usage:

-

Injection machine

-

Shipping way:

-

DHL,UPS,Fedex

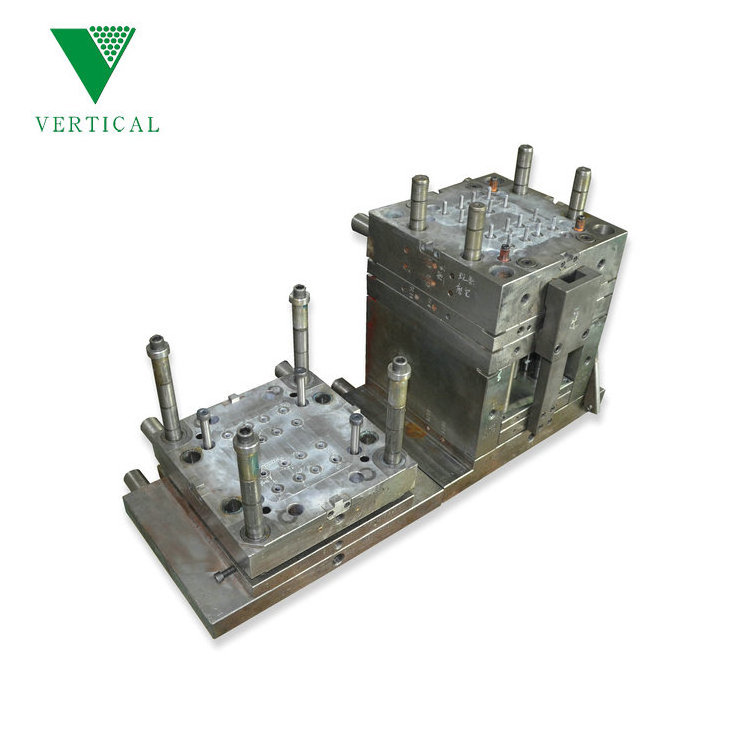

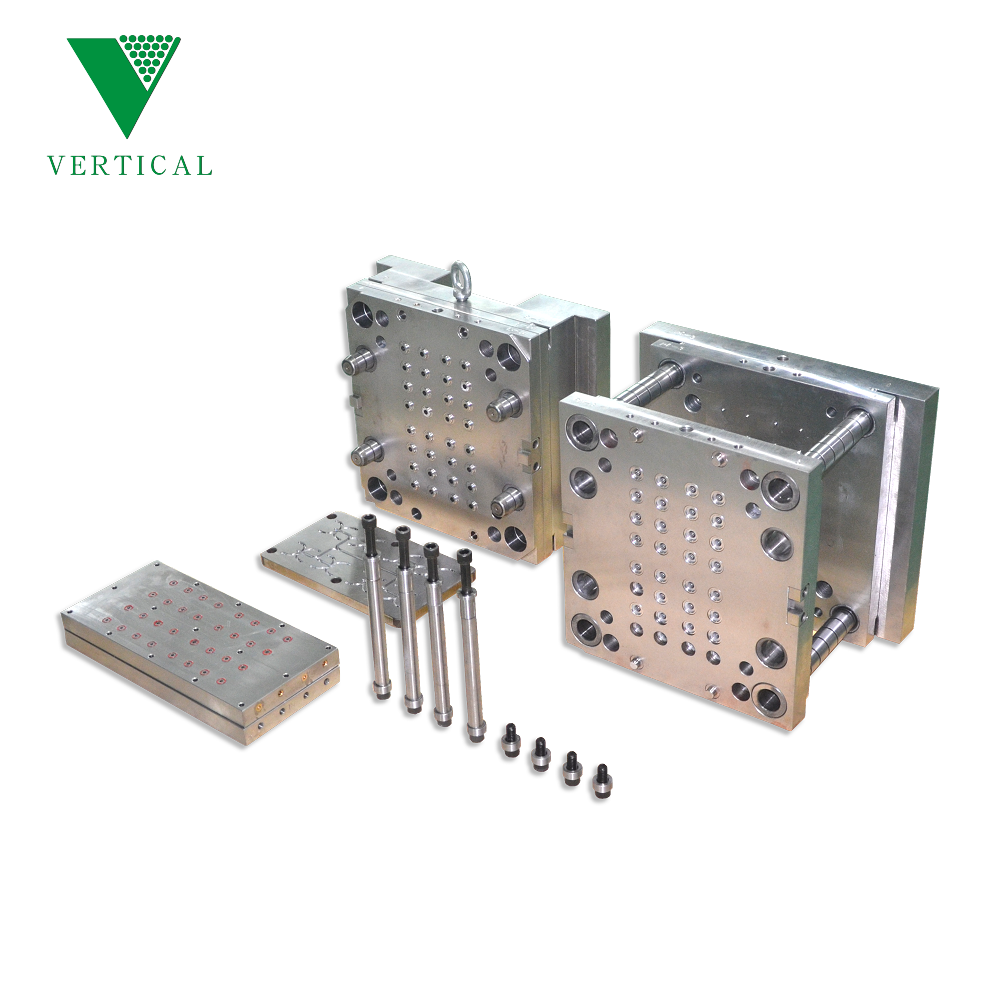

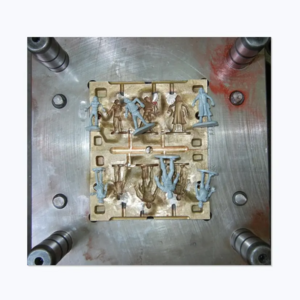

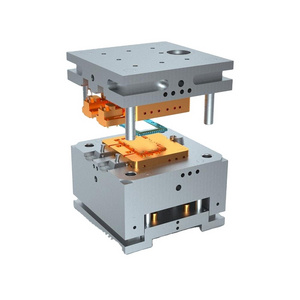

Product Description

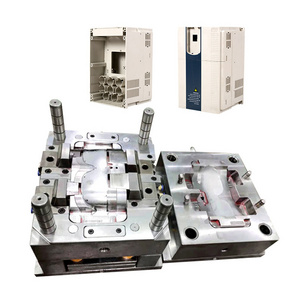

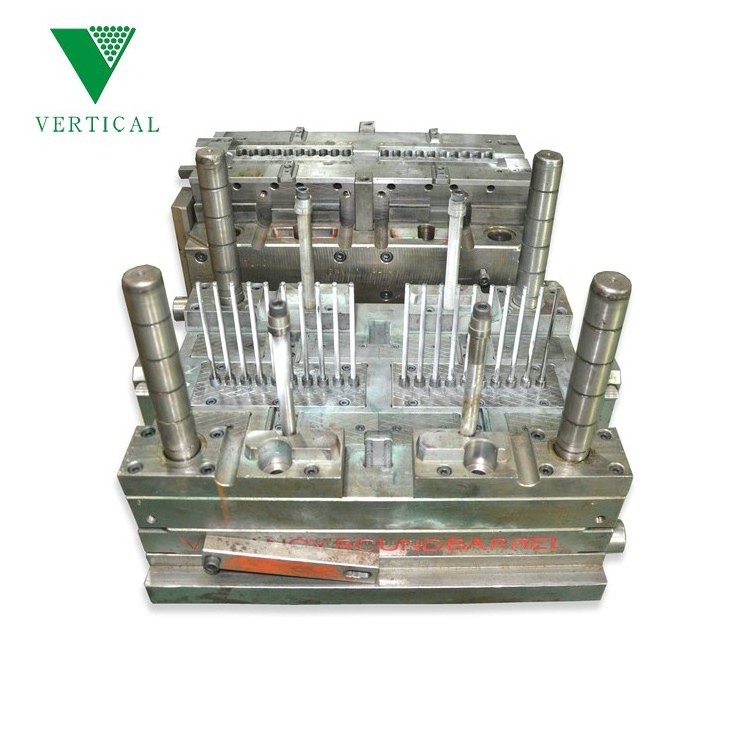

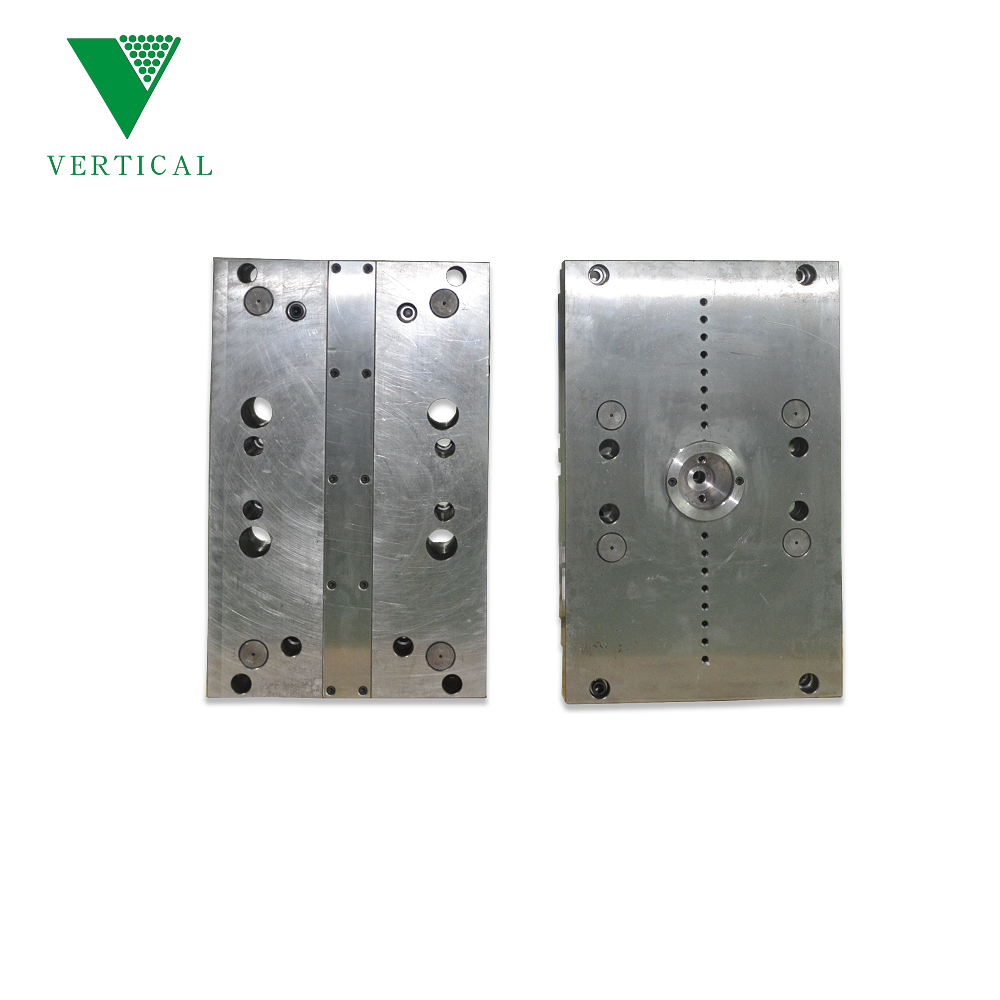

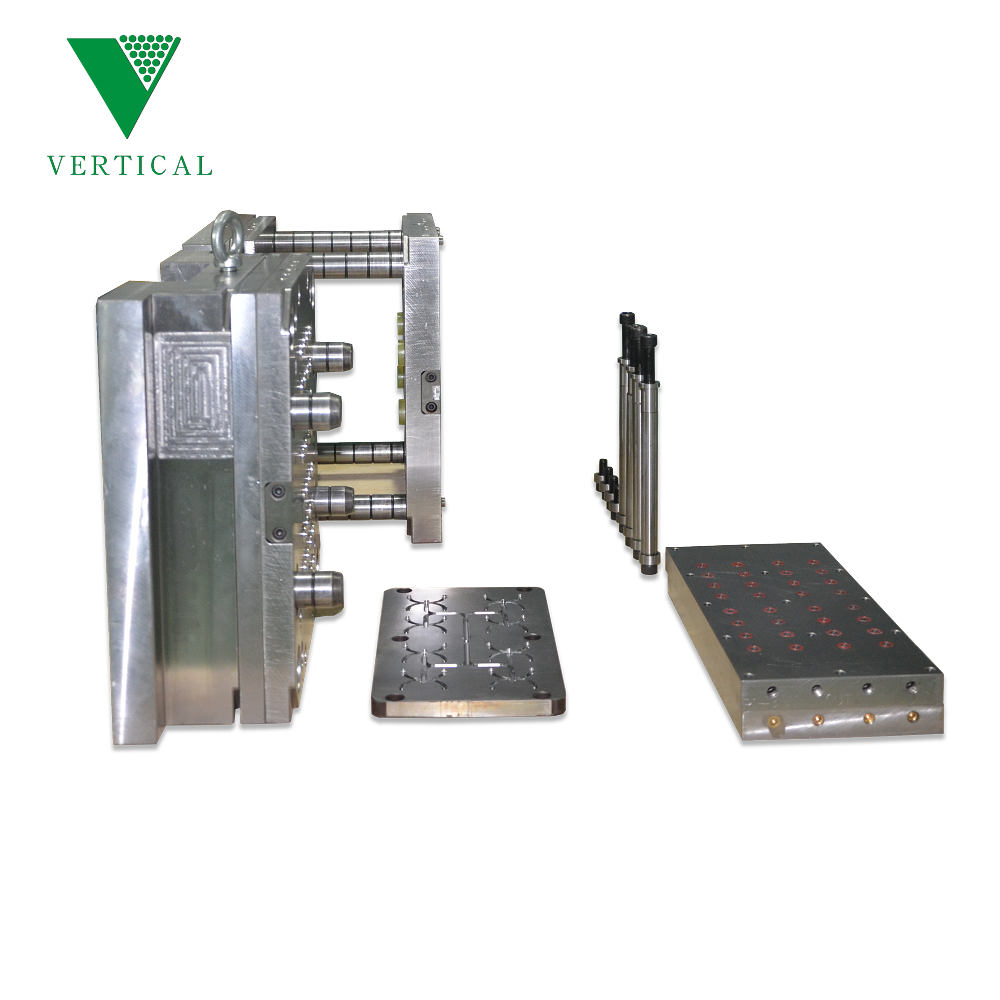

Injection mold plastic mold plastic products

Injection molds are suitable for producing various shapes of plastic products, such as bottle caps, sockets, pens, fan blades

|

Name

|

Tooling plastic injection mold manufacturer

|

|

Feature

|

OEM/ODM, 10 years experiences on pen mold

|

|

Packing

|

Plastic or bubble bag pack

|

|

Hardness

|

HRC42-60

|

|

Surface finish

|

Polish/Mirrow/Matte

|

|

Usage

|

Injection machine

|

|

Delivery Time

|

15 Days

|

|

MOQ

|

1PCS

|

Plastic mould

Direction for use

1.Before installation, check that the mounting surfaces of the upper and lower molds on the press are clean, and check whether there are remnants after the molds are ground to prevent the correct installation and accidents.

1. Install the mold on the work surface according to the press selected in the design manual, and install the mold correctly to ensure that the center of the mold coincides with the center of the press.

2. Open the mold to confirm that there is no foreign matter on the mold surface and make sure that the positioning pin is in the correct position.

Make sure there are no foreign objects on the mold guide surface.

3. When the mold makes an abnormal sound during use, it should immediately stop working. The mold repairer on site will check and eliminate the fault. The mold should be loaded and unloaded in the storage state.

Detailed Images

Related Products

Packing&Shipping

Port

:

GuangZhou or ShenZhen

Packing

:

Plastic or bubble bag pack

Shipping

:

DHL,UPS,Fedex

After Sales Service

The company regards quality as life

1. The company will deliver the goods on time and in strict accordance with the contract.

2. Provide complete product design drawings (2D / 3D)

3. If there is a non-human problem within one year, we will replace or repair it for free and actively solve the problem.

4. Non-quality problems of our products will be assisted, and the problem will be solved before the next batch.

Company Introduction

As a result, Mr. Fandra registered his company in Vertical China. Why choose a vertical name?

This is because the business is sourcing and trading between China and Indonesia (if we see the world map from north to south, it is called vertical). *

Vertical name dedicated to Mr. David Acor *

The next year, August 2011, Green Century was established in Medan. The company is responsible for exporting agricultural products from Indonesia to China, of which-

It is palm kernel shell.

Closely related to Indonesia's industrial development, in January 2012, Mr. Fandra established a cooperative relationship with a plastic injection mold factory in Dongguan, which will mold the business

Promote to the Indonesian market and focus on this business. In the next three years (2015), the business expanded into the field of stamping and die casting dies.

Our Services & Strength

our client

Product production process

FAQ

Q1.Are you a trading company or factory?

A1:We are the plastic injection mold company which is the joint of trade and industry.

Q2:Where can I get product & price information?

A2:Send us inquiry e-mail(DRAWING,STEP or IGS), we will contact you as soon as possible.

Q3:What’s kinds of the information you need for quotation?

A3:Kindly please provide the product drawing in PDF/CAD,picture or sample,and will be better you can provide in STEP or IGS.

Q4:How can I get the sample quickly?

A4:We can produce the sample by using 3D prototype for you reference,it will take 3-5 days.

Q5: How long is your delivery time?

A5: Generally within 30 days.

Q6:How can you confirm the plastic injection mold you production is the one we need?

A1:We are the plastic injection mold company which is the joint of trade and industry.

Q2:Where can I get product & price information?

A2:Send us inquiry e-mail(DRAWING,STEP or IGS), we will contact you as soon as possible.

Q3:What’s kinds of the information you need for quotation?

A3:Kindly please provide the product drawing in PDF/CAD,picture or sample,and will be better you can provide in STEP or IGS.

Q4:How can I get the sample quickly?

A4:We can produce the sample by using 3D prototype for you reference,it will take 3-5 days.

Q5: How long is your delivery time?

A5: Generally within 30 days.

Q6:How can you confirm the plastic injection mold you production is the one we need?

A6:

We will provide samples and design drawings for customer confirmation

.

Hot Searches