- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v (it can be customized)

-

Power:

-

380

-

Dimension(L*W*H):

-

50m*40m*16m

-

Weight:

-

80000 kg

-

Capacity:

-

120T/h

-

Dust collector:

-

bag house

-

fuel:

-

light oil/heavy oil/gas/coal

-

Control system:

-

Computer or touch screen

-

Control system language:

-

English/French/Russian/Spanish

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shengmao

-

Voltage:

-

380v (it can be customized)

-

Power:

-

380

-

Dimension(L*W*H):

-

50m*40m*16m

-

Weight:

-

80000 kg

-

Capacity:

-

120T/h

-

Dust collector:

-

bag house

-

fuel:

-

light oil/heavy oil/gas/coal

-

Control system:

-

Computer or touch screen

-

Control system language:

-

English/French/Russian/Spanish

Product Description

Stationary asphalt mixing plant can be divided into two types. One is drum type and the other is compulsory type.

Drum type of asphalt mixing plant has no mixer. It uses drying drum to dry aggregates and mix them with bitumen. Usually, no ore powder is used. It is usually used to build small, low-level countryside road.

Compulsory type of asphalt mixing plant has mixer. There are scales for all materials to ensure accuracy of the asphalt formula. Ore powder will be added to the mixture and all materials will be mixed in mixer. Usually, bag house filter is used to protect theenvironment. It is widely used for high-standard road like expressway, national highway etc.

Currently, we have stationary asphalt mixing plant with the capacity from 40tph to 320tph. Welcome to contact us for details and quotations.

Drum type of asphalt mixing plant has no mixer. It uses drying drum to dry aggregates and mix them with bitumen. Usually, no ore powder is used. It is usually used to build small, low-level countryside road.

Compulsory type of asphalt mixing plant has mixer. There are scales for all materials to ensure accuracy of the asphalt formula. Ore powder will be added to the mixture and all materials will be mixed in mixer. Usually, bag house filter is used to protect theenvironment. It is widely used for high-standard road like expressway, national highway etc.

Currently, we have stationary asphalt mixing plant with the capacity from 40tph to 320tph. Welcome to contact us for details and quotations.

Detailed picture and specification

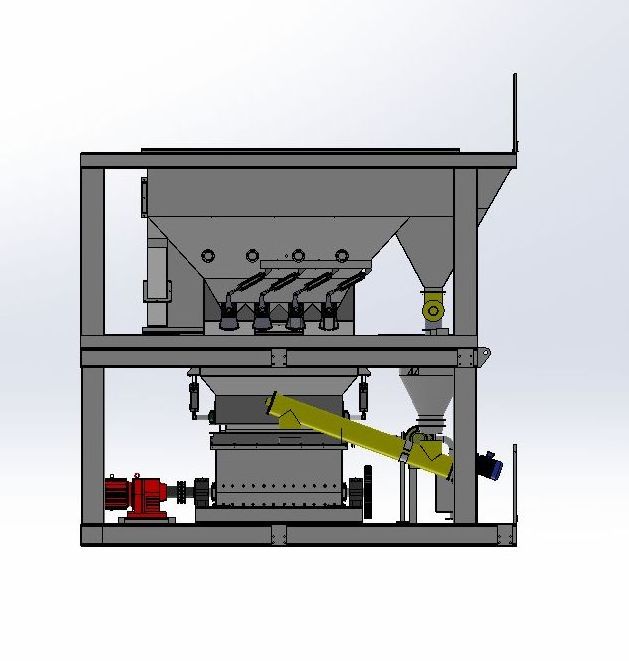

cold aggregate batcher

Cold aggregate batcher can has 4, 5 or 6 bins; it denpends on how many different types of stone used for asphalt.

Bitumen tank

Bitumen tank is used to store bitumen that are used to produce asphalt;

For LB1500 asphalt mixing plant, we use heat conduction oil to heat bitumen.

scales

For LB1500 asphalt mixing plant, all materials like stones, bitumen and ore powder are all weighed by weighing sensors. In this way, we can make sure the quality of the finished product.

bag type filter

Bag type filter is usually used for medium and big asphalt mixing plant.

The efficiency of smoke dedust is very good. The dust content of the exhaust gas is less than

50mg/Nm³

Control system

Control system is very important for an asphalt mixing plant. And it is usually very diffcult for customer to deal with it if there is a problem;

We use word famous brand for control system, like Siemens PLC, Schneider electrical parts. In this way, we can minimize the problems of the control system.

After Sales Service

Our service

Pre-sale Service

1 Answering customers' questions, helping customers choose the most suitable machines;

2.Making design drawings as per customers' requirements;

3. Providing quotations.

In-sale Service

1. Strictly control all prodedures from raw materials sourcing to pre-assembly to ensure product quality;

2. Regularly updating production production progress to clients;

3. After the production is completed, pre-assembly and test running will be carried out to make sure our machine works well;

4. Proper packing to minimize the risk that the machines are damaged during transportation;

5. Foundation drawing will be provided for clients to make foundation in advance.

After-sale Service

1. Providing 7 * 24 hours online after-sales service every week

2. Providing related certificates, customs clearance documents, operation and maintenance instructions, installation videos, etc.

3. Arranging engineers to go to client's job site. The engineers will help clients with the machine installation, machine

test-running and operators training etc.

4. Spare parts supply;

5. Job site visiting every year.

Pre-sale Service

1 Answering customers' questions, helping customers choose the most suitable machines;

2.Making design drawings as per customers' requirements;

3. Providing quotations.

In-sale Service

1. Strictly control all prodedures from raw materials sourcing to pre-assembly to ensure product quality;

2. Regularly updating production production progress to clients;

3. After the production is completed, pre-assembly and test running will be carried out to make sure our machine works well;

4. Proper packing to minimize the risk that the machines are damaged during transportation;

5. Foundation drawing will be provided for clients to make foundation in advance.

After-sale Service

1. Providing 7 * 24 hours online after-sales service every week

2. Providing related certificates, customs clearance documents, operation and maintenance instructions, installation videos, etc.

3. Arranging engineers to go to client's job site. The engineers will help clients with the machine installation, machine

test-running and operators training etc.

4. Spare parts supply;

5. Job site visiting every year.

FAQ

What's normal working condition?

1. Environmental temperature is 20 ℃ with standard atmospheric pressure; altitude ≤2000m;

2. Average moisture content of cold aggregate <5%;

3. Hot aggregate temperature <160 ℃;

4. Finished materials is medium-grained, the stone volume-weight ≥1600kg/m3;

5. Sand content <35%;

6. The ratio of aggregate shall meet the national standard. Dust content of cold aggregate ≤3%;

7. Cold aggregate should be clean enough without too much dirt or other material. Cold aggregate gradation should be continuous;

8. Cold aggregate shall not contain large amounts of oversized material, otherwise it will cause blocking, resulting in reduced

ability to supply aggregate;

9. Moisture content of powder must be less than 0.5%, and there should be no lumping or arching, otherwise it will cause

supplying interruption or lag, which can affect the productivity;

2. Average moisture content of cold aggregate <5%;

3. Hot aggregate temperature <160 ℃;

4. Finished materials is medium-grained, the stone volume-weight ≥1600kg/m3;

5. Sand content <35%;

6. The ratio of aggregate shall meet the national standard. Dust content of cold aggregate ≤3%;

7. Cold aggregate should be clean enough without too much dirt or other material. Cold aggregate gradation should be continuous;

8. Cold aggregate shall not contain large amounts of oversized material, otherwise it will cause blocking, resulting in reduced

ability to supply aggregate;

9. Moisture content of powder must be less than 0.5%, and there should be no lumping or arching, otherwise it will cause

supplying interruption or lag, which can affect the productivity;

Recommend Products

Hot Searches