This equipment is suitable for outer surface extrusion of wires and cables with insulation materials such as PVC/PE.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HH-50/70/80/90

-

Power supply:

-

65kw/h

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Weight:

-

5000KG

-

Warranty:

-

12 Months

-

Material:

-

45 Steel

-

Size:

-

27m(L)*3m(W)*3m(H)

-

Air Pressure:

-

0.5-0.8MPa

-

Wire range:

-

1.5-200 sqmm

-

Certification:

-

CE Certificate

-

Outlet diameter:

-

1-6mm

Quick Details

-

Use:

-

Extruding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HOOHA

-

Model Number:

-

HH-50/70/80/90

-

Power supply:

-

65kw/h

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Weight:

-

5000KG

-

Warranty:

-

12 Months

-

Material:

-

45 Steel

-

Size:

-

27m(L)*3m(W)*3m(H)

-

Air Pressure:

-

0.5-0.8MPa

-

Wire range:

-

1.5-200 sqmm

-

Certification:

-

CE Certificate

-

Outlet diameter:

-

1-6mm

MORE INFORMATION

Youtube: https://www.youtube.com/channel/UCrRUG2MnVoi8rfQ6FK2vYow

https://www.youtube.com/channel/UCKBDFWwJ8fuEs6P6T6CNF6g

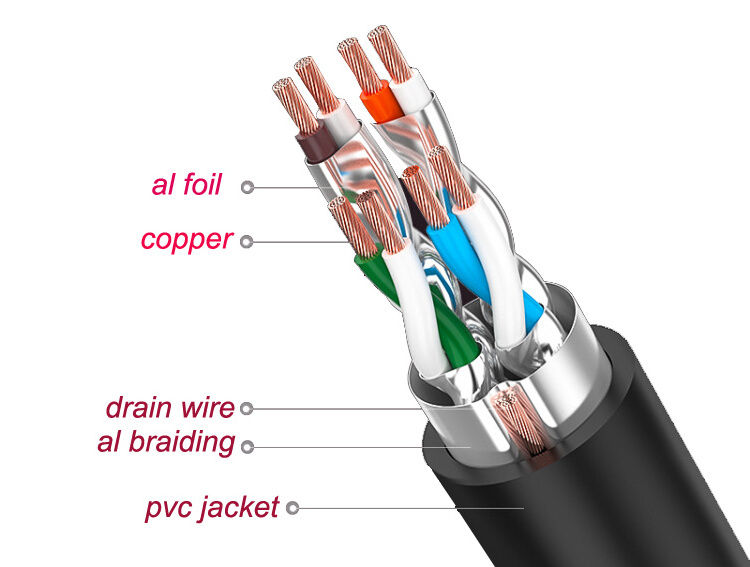

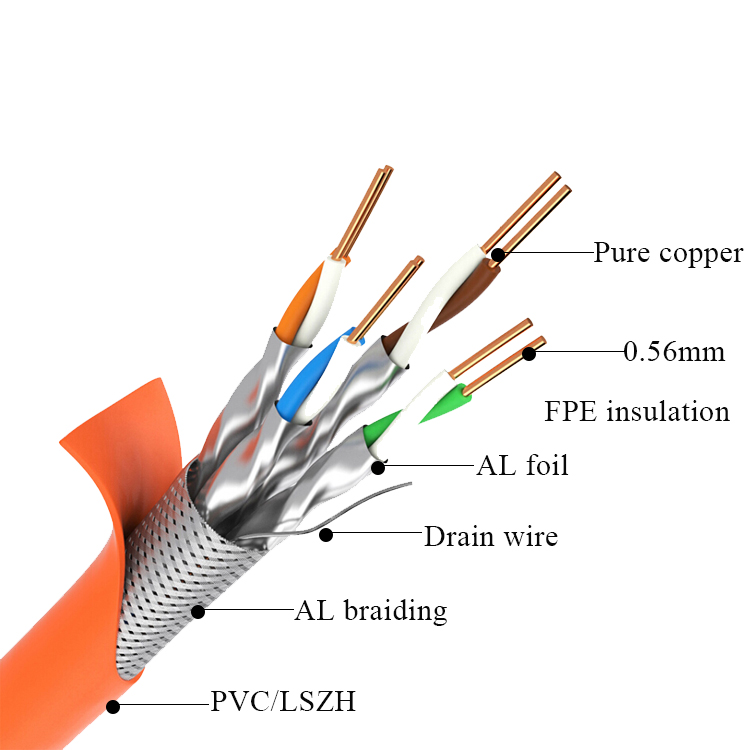

The Wire Samples

Products Description

Φ50+35 cable extrusion machine

|

Composition of extrusion machine

|

|

|

|

|||

|

No.

|

Description

|

Quantity

|

Remark

|

|||

|

1).

|

Shaftless active pay-off

|

1 set

|

|

|||

|

2).

|

Hot-air heating type preheater

|

1 set

|

|

|||

|

3).

|

Wire straightener

|

1 set

|

|

|||

|

4).

|

Φ50 Foaming extruder

|

1 set

|

|

|||

|

5).

|

Φ35mm stripping extruder +30 Stripping extruder

|

1 set

|

|

|||

|

6).

|

Auto-feedback thermostatic telescopic movable flume

|

1 set

|

|

|||

|

7).

|

Laser diameter gauge

|

1 set

|

|

|||

|

8).

|

Cooling flume

|

1 set

|

|

|||

|

9).

|

Accumulator

|

1 set

|

|

|||

|

10).

|

Capstan

|

1 set

|

|

|||

|

11).

|

Meter counter

|

1 set

|

|

|||

|

12).

|

Capacitance under water tester (BETA)British brand

|

1 set

|

|

|||

|

13).

|

High-frequency sparking tester

|

1 set

|

|

|||

|

14).

|

Dual-axises take-up

|

1 set

|

|

|||

|

15).

|

Electrical control system

|

1 set

|

|

|||

|

16).

|

Spare parts

|

1 set

|

|

|||

|

Optional parts

|

|

|

|

|||

Details Images

400-630 motorized pay-off stand

1 Bobbin size 400-630 mm

2 Loading 500 kg

3 Pay-off speed 500 m/min

4 Tension 5kg magnetic powder clutch

5 Main motor+Lift motor 3.7 kw + 0.75 kw

6 Material Q-235-A/Q-245-A/#45

50mm Mainframe

1 Insulation material PVC, PE 100% plasticization

2 Extrusion capacity Max 60 kg/h

3 Rotation speed Max 110 rpm

4 Motor 7.5 kw

5 Heating section 6

6 Cooling section 3

7 Temperature control PID automatic control, 0-399 ℃

8 Screw diameter 50 mm

9 Length/Diameter ratio 25/1

10 Center height 1000 mm

12 Material and process 38CrMoA1A alloy steel with nitriding treatment, chromed and polished

Φ318mm single pulley type belt drawer parameters

The pay off

1.The size can be 500/630/800/1250/1600mm

2.The head can be single and dual, or Tripe and more

4.The manual, motor,

magnetic powder control the pay off

The feeding and heating part

1.The speed can follow the machine working speed

2.The Famous brands we use

3.10 years no need repair

The Siemens system PLC control box

1.The Omron/

Schneider/RKC/YANGMING can be chose for control table

2.The system SIEMENS

3.The touch screen Siemens

Single screw extrusion process

Single-screw extruders are used extensively in the plastics industry for melting polymers, incorporating additives (for example

fillers, colouring pigments, stabilizers) and delivering a homogenized melt at high pressure to a die prior to shaping processes.

The granular or powdered feed from a hopper is fed onto the screw and there is an initial region, the ‘solids conveying zone’,

before any melting commences. This is followed by a ‘melting zone’ where the melting of the polymer occurs gradually. After this

melting region the helical channel between the screw and the barrel is filled completely with melt and in the final ‘metering

zone’ the melt is pumped to the die. Here the pressure increases as the die is approached. Thus in the metering section the

relative motion between the screw and the barrel creates a ‘drag flow’ towards the die. This is opposed by the ‘pressure flow’

from the die towards the hopper11,12,17,18. The net output of the extruder is the difference between the drag flow and the

pressure flow.

fillers, colouring pigments, stabilizers) and delivering a homogenized melt at high pressure to a die prior to shaping processes.

The granular or powdered feed from a hopper is fed onto the screw and there is an initial region, the ‘solids conveying zone’,

before any melting commences. This is followed by a ‘melting zone’ where the melting of the polymer occurs gradually. After this

melting region the helical channel between the screw and the barrel is filled completely with melt and in the final ‘metering

zone’ the melt is pumped to the die. Here the pressure increases as the die is approached. Thus in the metering section the

relative motion between the screw and the barrel creates a ‘drag flow’ towards the die. This is opposed by the ‘pressure flow’

from the die towards the hopper11,12,17,18. The net output of the extruder is the difference between the drag flow and the

pressure flow.

Detecting Unit

Online outside concave-convex detector

Accurate eccentric instrument

Water electrostatic capacity tester

The best device to detect the surface defects of wire and cable so far . Provided by Japan TAKANO , it adopts high-precision laser projection technology , able to detecting possible flaw like fracture , projecting wire or fiber , speckle , convex , concave , splice , etc .

It's for detecting and monitoring the distance between the center of the cable and wire to the outer surface , controlling the specs influenced by it .

It's developed a new online digital water electrostatic capacity measuring instrument based on the existing on-line water electrostatic capacity measuring instrument by integrating the new technology and new process in the field of current measurement and digital signal processing . Provided by Beta LaserMike .

Installation Instructions

The after service

1.Engineer guide installation video

2.The machine will doing the test before delivery and will send online test video

3.The drawing for install, electrical,die,screw will send to client

The technical support

1.The machine arrangement in the factory

2.The cable making production technical card

3.The engineer guide the cable making solution

4.The power, air,water arrangement guide

Hot Searches