- Product Details

- {{item.text}}

Quick Details

-

Weight (T):

-

3 T

-

Power (kW):

-

36

-

Applicable Industries:

-

Die casting

-

Application:

-

Melting Metal

-

Product Name:

-

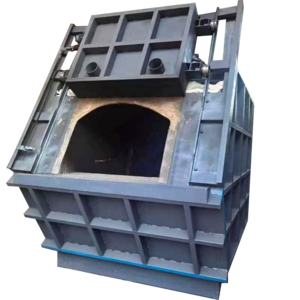

Induction Metal Melting Furnace

-

After-sales Service Provided:

-

Engineers

-

Melting Material:

-

Aluminium Scrap

-

Keyword:

-

Induction Melting Heating

-

Name:

-

Aluminum Induction Melting Furnace

-

Capacity:

-

10kg~50ton

-

Certification:

-

ISO9001

-

Function:

-

Melting Magnetic Metal

-

Furnace type:

-

Induction Melting Electric Furnace

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HYDEB

-

Voltage:

-

380V

-

Weight (T):

-

3 T

-

Power (kW):

-

36

-

Applicable Industries:

-

Die casting

-

Application:

-

Melting Metal

-

Product Name:

-

Induction Metal Melting Furnace

-

After-sales Service Provided:

-

Engineers

-

Melting Material:

-

Aluminium Scrap

-

Keyword:

-

Induction Melting Heating

-

Name:

-

Aluminum Induction Melting Furnace

-

Capacity:

-

10kg~50ton

-

Certification:

-

ISO9001

-

Function:

-

Melting Magnetic Metal

-

Furnace type:

-

Induction Melting Electric Furnace

Foundry Industry 20/410 Aluminium Treatment Pump Aluminum Ash Heat Treatment Furnace

•The vertical aluminum solution-hardening furnace, also known as drop-bottom aluminum solution-hardening furnace, is a heating furnace for periodic heat treatment, used for production of ultrahigh-quality workpieces in the war, aerospace, automobile manufacturing and high-voltage electrical equipment industries.

• Small batch, high quality-the best choice for solution treatment of aluminum!!

• Small batch, high quality-the best choice for solution treatment of aluminum!!

|

1

|

Power Supply

|

380V±10%, 50Hz±5%, 3P

|

|

2

|

Compressed air

|

|

|

3

|

Pressure

|

≥0.6MPa

|

|

4

|

Flow

|

≥20 m3/h ≥20 m3/h (a gas storage tank can be set in case of insufficient flow)

|

|

3

|

Maximum heating temperature

|

600℃

|

|

4

|

Common temperature

|

500-540℃

|

|

5

|

Furnace temperature uniformity (during maintaining temperature)

|

≤±3℃

|

|

6

|

Temperature control precision (during maintaining temperature)

|

≤±1℃

|

|

7

|

Maximum charging capacity (including charging basket weight)

|

6000Kg/furnace

|

|

8

|

Maximum lifting capacity of the lifting gear in charging basket

|

10000kg

|

|

9

|

Temperature rise for the furnace shell surface (main parts)

|

≤35℃

|

|

10

|

Temperature rise time of an empty furnace (maximum heating load to 550°C)

|

≤2h

|

|

11

|

Workpiece quenching and transfer time

|

≤12S

|

|

12

|

Effective working area size (charging basket size) (length × width × height)

|

36m3 at maximum

|

|

13

|

Equipment noise (over 1.5m away from the working face)

|

<80db

|

• There is a flexible sealing connection between the furnace door and the furnace body; the furnace door is pneumatically compacted, ensuring the synchronous sealing performance of the whole sealing surface.

• Each mechanical action is equipped with a perfect self-locking function, ensuring operation reliability and safety. Especially,there is a well-designed logical relation and reliable hardware-software logic interlocking circuit among the heating system, fan operation system, furnace door switch system, charging basket lifting system, water tank movement system and mixing system. They can keep the equipment and thermal treatment device safe in case a sequence error is caused by manual operation or a failure occurs in an action process during automatic operations.

• High furnace temperature uniformity. A large-flow and high-air-pressure heat-resisting fan is adopted, able to generate enough recirculating air quantity and pressure; the super-large furnace consists of multiple temperature control zones including "one main zone", ensuring that temperature rises synchronously in all of the temperature control zones; the all-fiber furnace lining minimizes heat loss, ensuring that the furnace chamber temperature gradient is within a certain range.

• High furnace temperature control accuracy. Multiplex control maximally ensures that the furnace chamber does not overheat, thus protecting workpieces from being "softened" and over-burnt.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hot Searches