- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

±0.05

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Ronen

-

Year:

-

2022

-

Power (kW):

-

40

-

Weight (KG):

-

2500

-

Marketing Type:

-

New Product 2022

-

Keywords:

-

CNC Mandrel Tube Bender

-

Delivery Time:

-

Delivery on time, Without delay

-

Price:

-

Factory direct supply price

-

After-Sales Service:

-

Provide solutions within 24 hours

-

Function:

-

Tube bending

-

Installation:

-

Available

-

Power:

-

Hydraulic, CNC

-

Type:

-

CNC,NC,PLC

-

Control:

-

Automatic, Fully automatic

-

Certification:

-

CE

Quick Details

-

Machine Type:

-

CNC Intelligent Equipment

-

Bending Radius (mm):

-

90 - 800

-

Max. Bending Angle (Deg):

-

200

-

Bending Precision (Deg):

-

±0.05

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Ronen

-

Year:

-

2022

-

Power (kW):

-

40

-

Weight (KG):

-

2500

-

Marketing Type:

-

New Product 2022

-

Keywords:

-

CNC Mandrel Tube Bender

-

Delivery Time:

-

Delivery on time, Without delay

-

Price:

-

Factory direct supply price

-

After-Sales Service:

-

Provide solutions within 24 hours

-

Function:

-

Tube bending

-

Installation:

-

Available

-

Power:

-

Hydraulic, CNC

-

Type:

-

CNC,NC,PLC

-

Control:

-

Automatic, Fully automatic

-

Certification:

-

CE

Company Introduction

Ronen Group

is dedicated to

manufacturing series of welded pipe roll forming&welding production lines, pipes bending forming lines and various auxiliary forming equipment and shot blasting machine.

The company is headquartered in Beijing, and its manufacturing workshop is located in Baoding and Cangzhou. It provides high quality equipment for domestic and foreign pipe and auto parts customers, with rich experiences of serving the industrial field for more than 20 years, RGL becomes a reliable professional pipe equipment supplier and life time partner. RGL does not only provide machines, but also the know-how on specific products making thanks to backup by a consultancy team consists of many top professors-being called “Craftsman”, we are confident to guarantee all our customers that our manufacturing level/serving level ranks at the top all over China. We follow up the principle of “ZERO FAULT”on each steps of business with you.

Ronen

will always be here for you!

Pipe Bending Machine Description

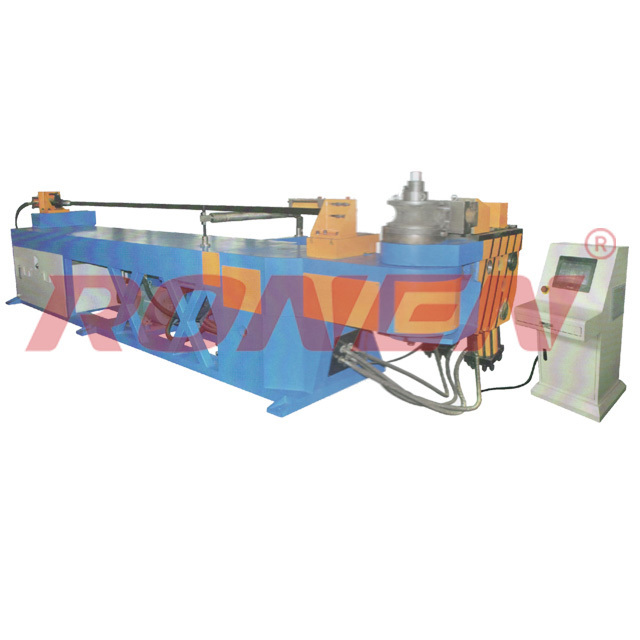

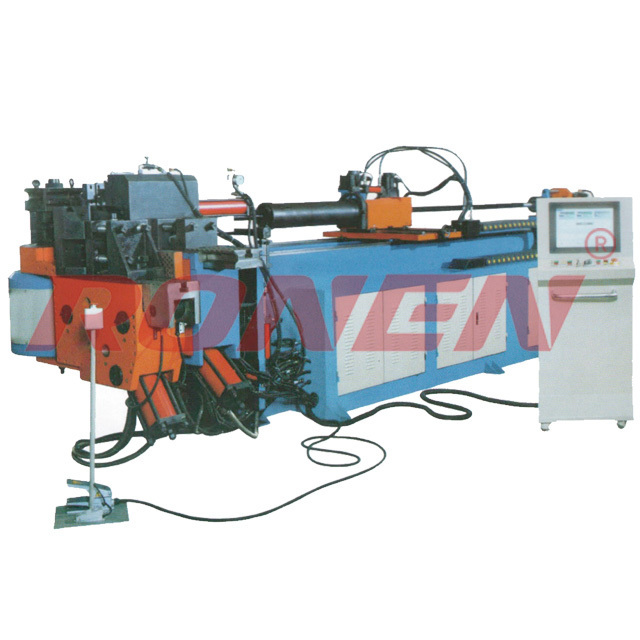

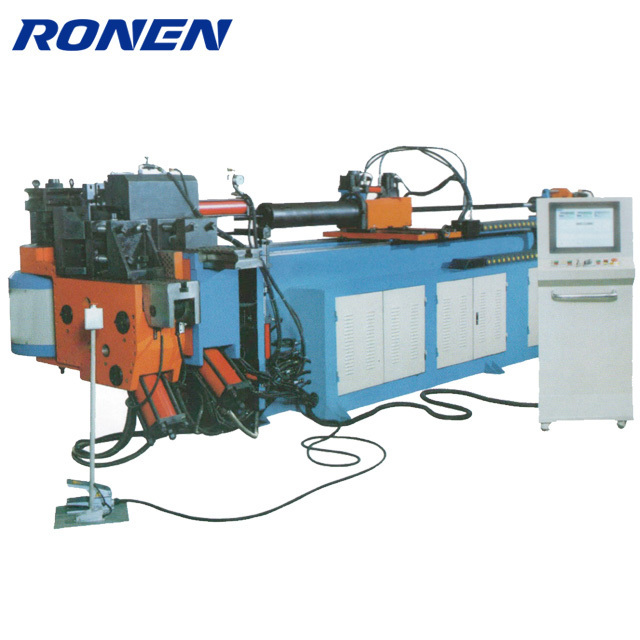

Factory Price 1 2 3 4 5 Inch 3D Automatic Exhaust Round Square Pipe Hydraulic Bending Machine CNC Mandrel Tube Bender

/

Tube Bender

/ Single-Head Hydraulic Bending Machine

CNC Hydraulic Exhaust Pipe Bending Machine

|

Features

|

|

1. PLC controlled, quite stable operation.

|

|

2. Multiple functions of manual operation, automation, semi--circulation, full

circulation. |

|

3. Setting 16 angles (any of 0 to 185 degrees), selecting one angle or continuously selecting two angles.

|

|

4. Mobile type pedal switch having functions of automatic starting, urgent shutdown and instant stop continuing,high safety.

|

|

5 Big volume cooling circulation system. smooth machine operation.

|

|

6. Simple and easy change of die, convenient elastic production.

|

|

7.Machine head, well designed bending tubes maximum space for bending tubes

|

|

Vehicle Fittings (Brake Hoses, Bumpers, Muflers and Seats). Industries: Motorcycle Making, Fitness Apparatus,Air Conditioning Refrigeration, Bicycle Industry, Steel Furniture and bathroom equipment.

|

High Speed Electric CNC Pipe Bending Machine

|

Features

|

|

1. Low cost for operator training, high producticn efficiency and product unitormity.

|

|

2. Drived by electric servo motors. Compared with hydraulic drive, it has higher stability and longer lifetime, It is unnecessary to warry about oil-leak or working temperature.

|

|

3. Gapless tube bending, with long- time high precision and processing efficiency, easy tor operation. It has good

compatibility. |

|

4. Small in size, low noise level.

|

|

5. Low running cost, with best cost perfermance for tube processing.

|

|

6. Widely used in small diameter tube processing, for example tubes of air conditioner and oil tube for autos.

Standard models: 1- 5 stacks,

4-6 servo motors.

Advanced models:11 fully electric servo motors.

|

Standard Machine Model

Pipe Bending Machine Technique Parameter

|

Model

|

|

CNC100

|

CNC130

|

CNC168

|

CNC219

|

|

|

|

Mild Steel

|

101.6x4t

|

φ127x8t

|

168x14t

|

219x16t

|

|

|

|

S.S Tube

|

90x2.0t

|

φ114x3.0t

|

150x10t

|

189x14t

|

|

|

|

Rectangle Tube

|

90x2.0t

|

φ100x3.0t

|

150x10t

|

189x14t

|

|

|

Max. Bending Radius

|

|

400mm

|

450mm

|

550mm

|

800mm

|

|

|

Max. Bending Angle

|

|

190°

|

190°

|

190°

|

190°

|

|

|

Max.Etecive Distance of Mandrel

|

|

4000mm

|

4500mm

|

4500mm

|

6000mm

|

|

|

Bending

|

Precision

|

±0.1

|

±0.1

|

±0.1

|

±0.1

|

|

|

|

Speed (per sec.)

|

50°

|

38°

|

38°

|

38°

|

|

|

Feeding

|

Precision

|

±0.05

|

±0.05

|

±0.05

|

±0.05

|

|

|

|

Speed (per sec.)

|

650mm

|

580mm

|

580mm

|

580mm

|

|

|

Rotation

|

Precision

|

±0.05

|

±0.05

|

±0.05

|

±0.05

|

|

|

|

Speed (per sec.)

|

120°

|

100°

|

100°

|

100°

|

|

|

Max Distance between 2R

|

|

75

|

80

|

80

|

80

|

|

|

Size

|

|

7500x2000x2200mm

|

1000x2200x2750mm

|

9100x1955x1660mm

|

10500x2450x1980mm

|

|

|

Weight

|

|

11000kg

|

13000kg

|

29000kg

|

38000kg

|

|

1. Standard display text: Chinese/English switch. (Other text can be changed as needed)

2. The maximum bending program memory capacity of 400 groups, each group can be programmed up to 16 bends. ( expandable)

3. Directly input the bending pipe processing parameters. The machine can be single-stepped and paused during automatic operation,so that it can be manually intervened when bending special pipe fittings, and can also resume automatic operation. At the same time, it has a pause function, with automatic and manual functions. It is activated by a switch when running the next cycle after one cycle, and an emergency stop button is required when an emergency stop is required.

4. The operating program and the elbow program have unlimited memory storage time, and will not cause program loss due to power outage or long-term non-use.

5. While the machine is performing automatic machining, the controller can still input or edit the program.

6. With XYZ coordinate value to YBC processing value conversion function, convenient for operators to use.

7. The elbow program can set the individual movements of each axis from 0 to 10 speeds in each machining step to flexibly apply to different work items and improve work efficiency. An external speed knob is also available to reduce or increase the machining speed as needed.

8. Automatically has the back pull feeding and reciprocating feeding function for switching to meet the processing requirements of different pipe fittings.

9. Equipped with processing capacity and processing time counting function.

10. Using the absolute origin system, re-boot in the morning or after the break, without the need to find the origin of each axis without complicated procedures, you can immediately enter the work standby state.

11. The screen synchronously displays the position and bending angle of each action axis of the machine.

12. The control program has a text display function for automatically detecting errors and countermeasures. The information of the machine malfunction or illogical operation is directly displayed on the screen, and the repair method is explained to prevent human error and damage the machine and relatively reduce the difficulty of maintenance. The above-mentioned automatic detection of the alarm message records can be automatically stored as a reference for future maintenance.

13. Automatic or manual time mode setting function can be set according to the nature of the work, a variety of different working modes, such as the presence or absence of the heart, auxiliary push and other different states to improve production efficiency.

14. With multiple delay parameter settings, the most appropriate time difference can be set for each action axis to meet a variety of bending changes.

15. With the automatic detection function of each button and circuit output/input board, it is easy to find the location of

possible faults.

16. The machine has an automatic lubrication system to protect the machine transmission parts and improve the service life of the machine.

17. The machine control adopts closed-loop control.

2. The maximum bending program memory capacity of 400 groups, each group can be programmed up to 16 bends. ( expandable)

3. Directly input the bending pipe processing parameters. The machine can be single-stepped and paused during automatic operation,so that it can be manually intervened when bending special pipe fittings, and can also resume automatic operation. At the same time, it has a pause function, with automatic and manual functions. It is activated by a switch when running the next cycle after one cycle, and an emergency stop button is required when an emergency stop is required.

4. The operating program and the elbow program have unlimited memory storage time, and will not cause program loss due to power outage or long-term non-use.

5. While the machine is performing automatic machining, the controller can still input or edit the program.

6. With XYZ coordinate value to YBC processing value conversion function, convenient for operators to use.

7. The elbow program can set the individual movements of each axis from 0 to 10 speeds in each machining step to flexibly apply to different work items and improve work efficiency. An external speed knob is also available to reduce or increase the machining speed as needed.

8. Automatically has the back pull feeding and reciprocating feeding function for switching to meet the processing requirements of different pipe fittings.

9. Equipped with processing capacity and processing time counting function.

10. Using the absolute origin system, re-boot in the morning or after the break, without the need to find the origin of each axis without complicated procedures, you can immediately enter the work standby state.

11. The screen synchronously displays the position and bending angle of each action axis of the machine.

12. The control program has a text display function for automatically detecting errors and countermeasures. The information of the machine malfunction or illogical operation is directly displayed on the screen, and the repair method is explained to prevent human error and damage the machine and relatively reduce the difficulty of maintenance. The above-mentioned automatic detection of the alarm message records can be automatically stored as a reference for future maintenance.

13. Automatic or manual time mode setting function can be set according to the nature of the work, a variety of different working modes, such as the presence or absence of the heart, auxiliary push and other different states to improve production efficiency.

14. With multiple delay parameter settings, the most appropriate time difference can be set for each action axis to meet a variety of bending changes.

15. With the automatic detection function of each button and circuit output/input board, it is easy to find the location of

possible faults.

16. The machine has an automatic lubrication system to protect the machine transmission parts and improve the service life of the machine.

17. The machine control adopts closed-loop control.

Finished Products Display

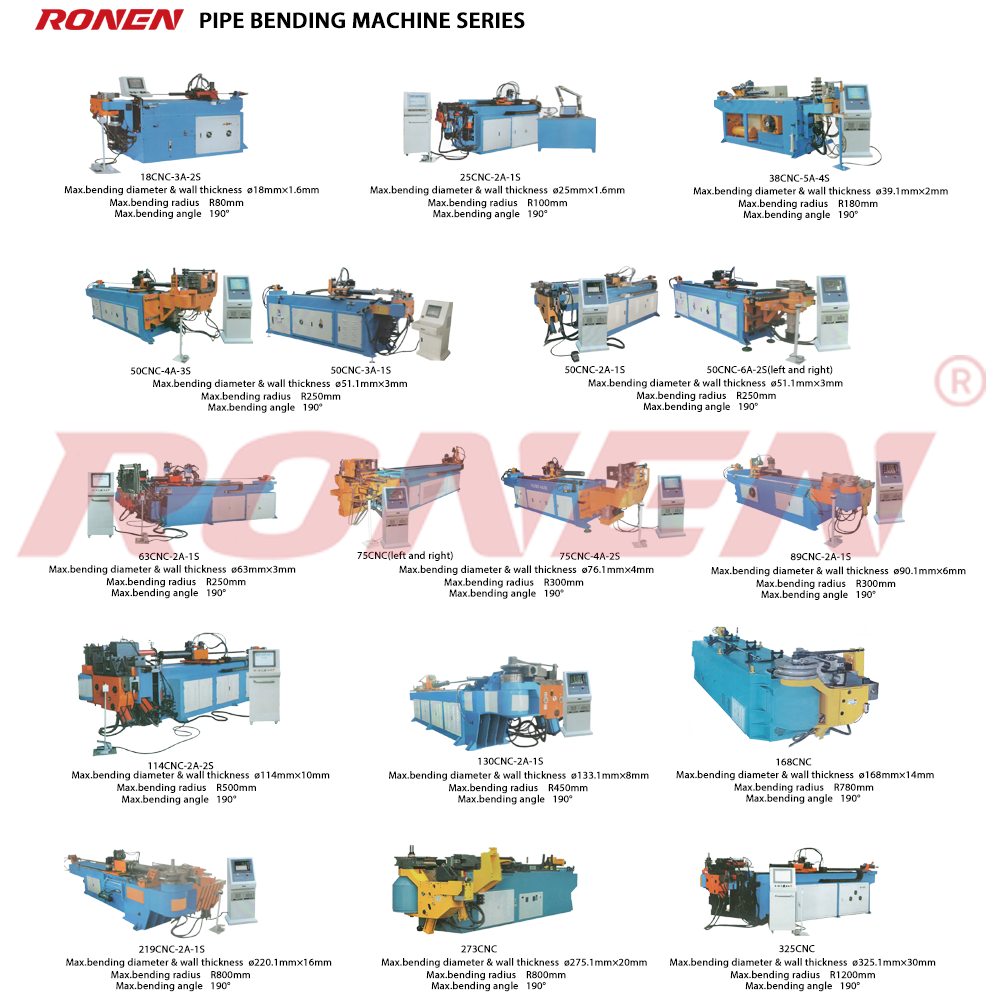

Recommend Products

Ronen Workshop

Certifications

FAQ:

Q: Are you manufacturer?

A:Yes, We are

manufacturer

.

Q: What is our factory product range?

A:

Manufacturing series of welded pipe roll forming&welding production lines, pipes bending forming lines and various auxiliary forming equipment and shot blasting machine

Q: How to order?

A:Please send us your inquiry by email, send message through

Alibaba , Wechat, Whatsapp

or others as you want.

Q: What are the payment terms?

A: Pattern :we can accept

T/T,Western Union ,Money Gram

.

Q: What is the whole business flow cooperation with us?

A: 1.Firstly,

send your inquiry

to us, make us have learned your requirement

2.We will be drawing a

proforma invoice

according to your requirement ,and start production after you finished to pay 30% deposit.

3.All of the goods, packing details will be send to buyer after finished production. We will

arrange shipment and the buyer finished to pay the balance

.

Hot Searches