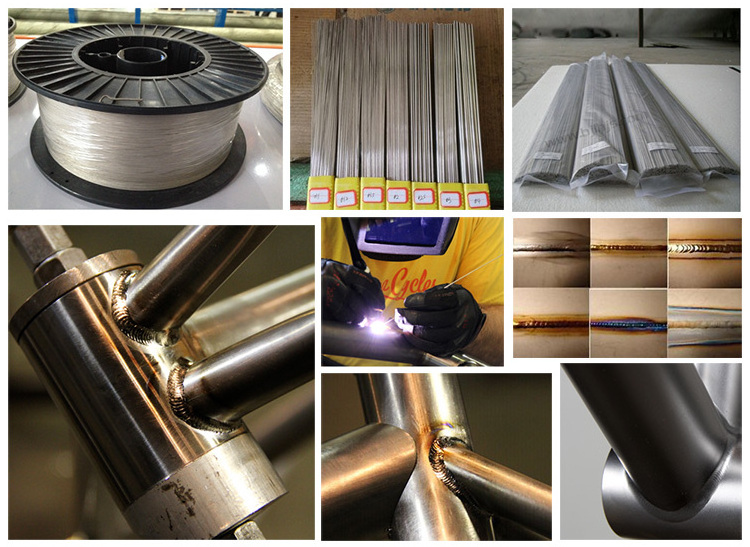

1. Nitinol spring: nitinol push and pull spring is a kind of spring used for orthodontic treatment. It has the characteristics of nitinol super elasticity, and is suitable for orthodontic treatment, opening up the space between teeth and pulling teeth in different directions. A force of about 50 g can be produced by extending the NiTi coil spring by 1 mm. NiTi coil spring has high elastic properties, which can produce soft and stable continuous force under tensile state. The force attenuation is very small,which can produce ideal orthodontic force for clinical tooth movement. Meet the physiological requirements. Compared with the stainless steel wire of the same diameter, the force released by the Ni Ti wire spring is 3.5-4 times lower. Therefore, in the application of orthodontic treatment, patients not only have mild pain, soft and lasting feeling power, but also reduce the return visit time, shorten the course of treatment and improve the curative effect. It is a new excellent mechanical device in orthodontic treatment.

2. Because of the super elasticity, shape memory and low stress-strain curve of nitinol archwire, nitinol archwire is usually used as the initial archwire in orthodontic treatment system. In this way, the discomfort of patients will be greatly reduced. Because there are several kinds of straight wire orthodontic techniques, mbt technique recommends the use of 0.016 inch heat activated nickel titanium alloy arch wire (hant wire), demon self-locking bracket technique recommends the use of copper containing heat activated nickel titanium alloy arch wire (phase transition temperature is about 40 ℃), 0.016 inch super elastic Ni Ti alloy arch wire is recommended for early alignment in o-pak.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Titanium Wire

-

Grade:

-

Nickel Titanium Alloy

-

Ti (Min):

-

90%

-

Strength:

-

high

-

Surface treatment:

-

Pickling Polished

Quick Details

-

Application:

-

INDUSTRY

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

LH

-

Model Number:

-

Titanium Wire

-

Grade:

-

Nickel Titanium Alloy

-

Ti (Min):

-

90%

-

Strength:

-

high

-

Surface treatment:

-

Pickling Polished

Product Description

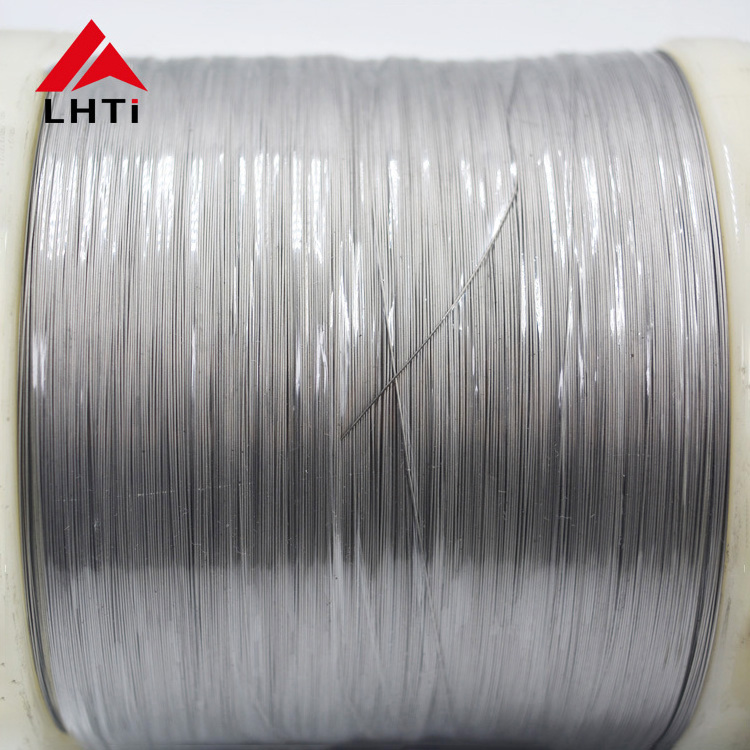

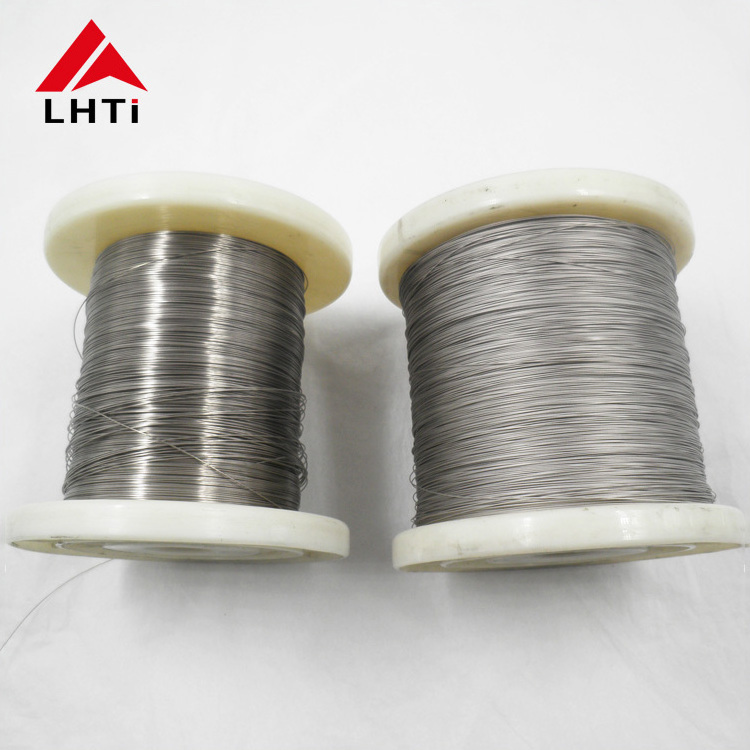

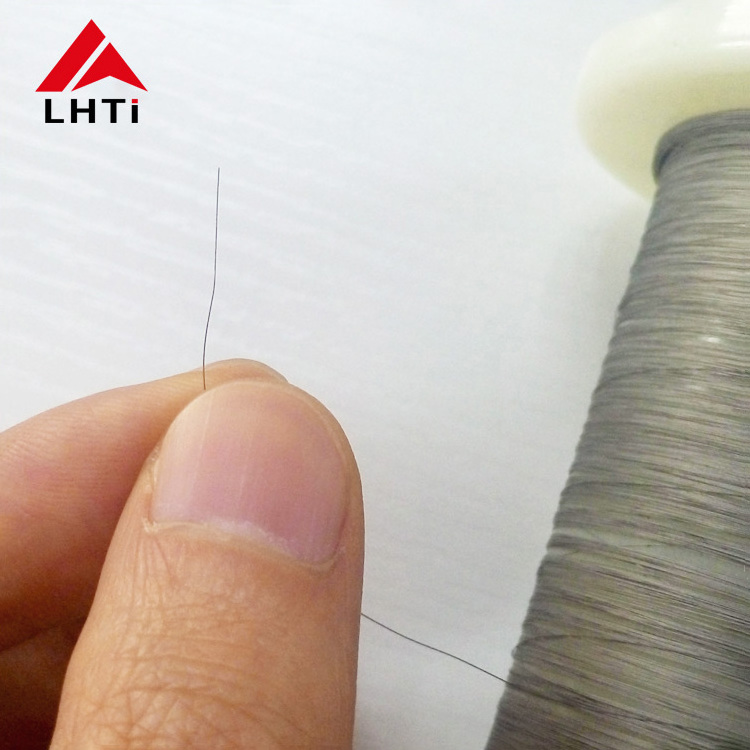

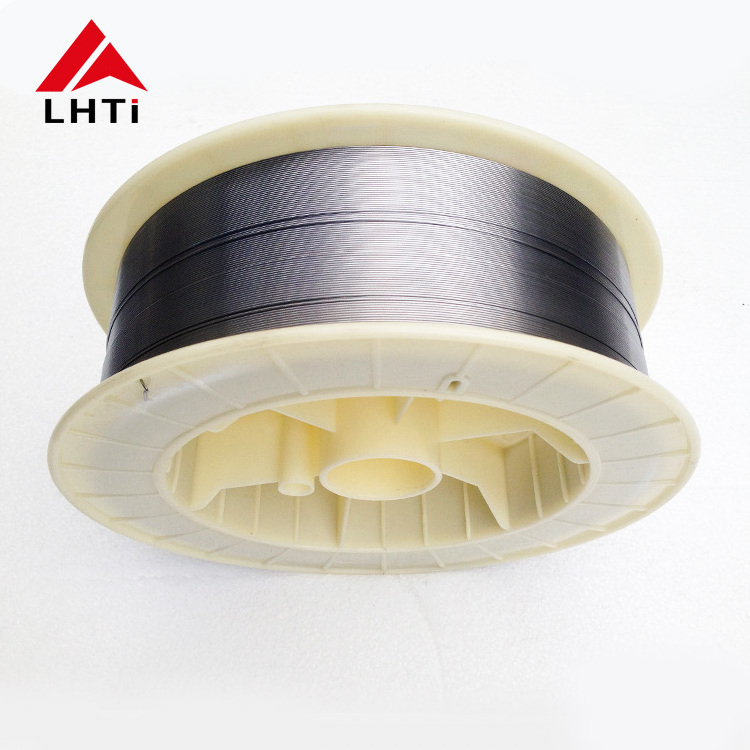

High Quality ASTM F2063 0.5mm 2mm 0.36mm mesh super elastic memory round metal polished nitinol alloy wire

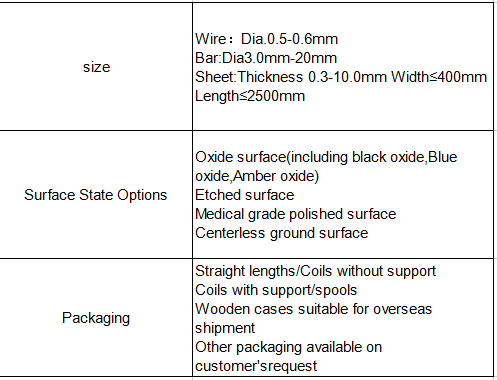

Specification

|

Alloy

|

|

composition |

Af(fully annealed)

|

Min. elongation to failure [%]

|

Max. Residual

elongation after 6% strain [%]

|

Main

Applications

|

|

|

Superelastic

Ni-Ti alloy

|

TiNi-SS

|

Ti-50.8at%

|

-5°C ± 5°C.

|

10

|

0.1

|

Eyeglass

Frames, Cellular Phone Antennae, Bra Underwire |

|

|

|

TN3

TNC |

TiNiVAl

TiNiCr |

-40°C ~50°C

|

10

|

0.1

|

|

|

|

Body temperature

Ni-Ti alloy

|

|

|

Functional(Af=33±3)

|

15

|

|

Implantable

devices, Bone staples Vascular Stents |

|

|

|

|

55.6~55.8 wt%Ni

|

20-40

|

15

|

0.1

|

Guide wires,

Stents Orthodontic Arches |

|

|

High temperature

Ni-Ti alloy

|

|

54.8~55.5wt%Ni

|

45 - 95

|

10

|

0.1

|

Implantable

active devices, Surgical tools, Thermostats Coffeepots |

|

|

|

TiNiCu

|

TiNiCu

|

As-Ms ≤ 5

|

10

|

0.1

|

|

|

Packing & Delivery

Hot Searches