- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

15KW

-

Weight (KG):

-

1200 KG

-

Product Name:

-

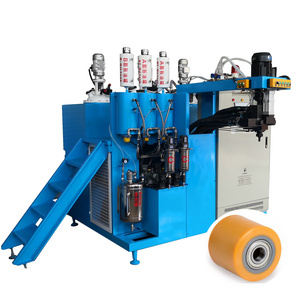

High Quality Polyurethane Foam Fill Tire Equipment for Motorcycle Seat

-

Applicable foam types:

-

MDI, TDI hard bubbles, soft bubbles

-

Injection pressure:

-

0.1 ~ 10kg (adjustable)

-

Injection traffic (mixed ratio 1: 1.1):

-

100~350g/s

-

Mixed ratio:

-

1: 1 ~ 1: 4 (adjustable)

-

Injection:

-

20-800 grams

-

Material temperature control error:

-

±2℃

-

Repeated injection accuracy:

-

1000g≤±1%

-

Tank volume:

-

300L

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huashang

-

Machine Type:

-

Foam injection machine

-

Power (kW):

-

15KW

-

Weight (KG):

-

1200 KG

-

Product Name:

-

High Quality Polyurethane Foam Fill Tire Equipment for Motorcycle Seat

-

Applicable foam types:

-

MDI, TDI hard bubbles, soft bubbles

-

Injection pressure:

-

0.1 ~ 10kg (adjustable)

-

Injection traffic (mixed ratio 1: 1.1):

-

100~350g/s

-

Mixed ratio:

-

1: 1 ~ 1: 4 (adjustable)

-

Injection:

-

20-800 grams

-

Material temperature control error:

-

±2℃

-

Repeated injection accuracy:

-

1000g≤±1%

-

Tank volume:

-

300L

Product Description

Product Feature

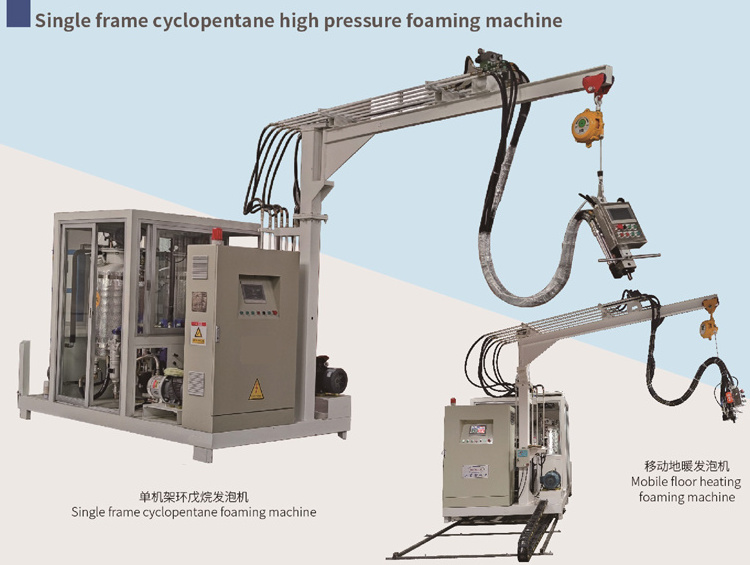

PU Foaming Machine Veneer Stone Production Line

1.Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

2.Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

3.Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

4.Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5.High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

6.Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors.

Specification

|

Product Name

|

PU Foaming Machine

|

|

Applicable foam types

|

MDI, TDI hard bubbles, soft bubbles

|

|

Mixed ratio

|

1: 1 ~ 1: 4 (adjustable)

|

|

Material temperature control error

|

±2℃

|

|

Repeated injection accuracy

|

1000g≤±1%

|

|

Temperature Control System

|

Thermal crew thermal exchange system

|

|

Mixed head

|

Needle or ball valve hybrid head

|

Related Products

Hot Searches