- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ainuok

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2600*1300*2300mm

-

Weight (KG):

-

3000 KG

-

Product name:

-

Ring die wood granulator

-

Raw material:

-

Biomass material, sawdust, rice husk , wood shaving etc

-

Application:

-

Wood Processing Plant, Feed Mill Plant, Fuel factory

-

Final size:

-

4mm, 6mm, 8mm,12mm etc

-

Machine type:

-

Ring Die Pellet Machine

-

Delivery time:

-

Within 10-15 days

-

Website:

-

www.ainuok.com

-

Power:

-

Electric motor

-

Color:

-

Customized

-

Pellet size:

-

4-12mm

Quick Details

-

Pellet Diameter (mm):

-

4 - 12

-

Output (kg/h):

-

800 - 3500 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ainuok

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2600*1300*2300mm

-

Weight (KG):

-

3000 KG

-

Product name:

-

Ring die wood granulator

-

Raw material:

-

Biomass material, sawdust, rice husk , wood shaving etc

-

Application:

-

Wood Processing Plant, Feed Mill Plant, Fuel factory

-

Final size:

-

4mm, 6mm, 8mm,12mm etc

-

Machine type:

-

Ring Die Pellet Machine

-

Delivery time:

-

Within 10-15 days

-

Website:

-

www.ainuok.com

-

Power:

-

Electric motor

-

Color:

-

Customized

-

Pellet size:

-

4-12mm

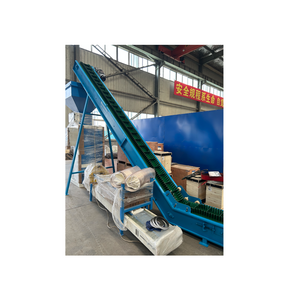

Ring die wood pellet alfalfa granulator mill biomass pellet press machine

Ring die wood granulator , has unique design of "double layer die" and high wearable alloy "rollers". It is used for making different biomass materials into pellets, an ideal press equipment with low investment and high profit.

Raw materials : rice husk, tree bark, peanut shell, sugarcane bagasse, rosewood, alfalfa, grass, straw, sawdust, coffee grounds, sunflower shell, cotton stalk, bamboo, jute residue, tealeaf residue, wheat straw, palm shell, bean shell, coconut shell, palm fiber, medicine residue etc.

Biomass pellet press mill Features :

1. Low wear rate, pressure roller die long service life

2. C ompact structure, high capacity, less power consumption

3. High Automation: 1-2 workers are enough to operate all the process.

4. Dies using vertical structure, d ies of hole diameters 4 - 12 mm are available , d ies diameters can customized.

5. Unique automatic lubricating system: p ress roller adopting automatic lubrication system, lubricate bearing, dies and rollers to increase produce efficiency and reduce energy consumption .

|

Model |

Die Dia (MM) |

Pellets Dia(MM) |

Dimension (MM) |

Weight (T) |

Capacity (T/H) |

Power(KW) |

|

K-450 |

450 |

Φ4-12 |

2.2*0.9*1.6 |

3 |

0.8-1 |

55 |

|

K-560 |

560 |

Φ4-12 |

2.6*1.3*2.3 |

5.8 |

1.2-1.5 |

90 |

|

K-600 |

600 |

Φ4-12 |

2.7*1.3*2.35 |

6.3 |

1.8-2.3 |

132 |

|

K-700 |

700 |

Φ4-12 |

2.9*1.3*2.4 |

7 |

2.5-3.0 |

160 |

|

K-850 |

850 |

Φ4-12 |

3.75*1.65*3.25 |

12.6 |

3.0-3.5 |

220 |

Note : Voltage 3 phases, 380V/50Hz, finished pellets size can be 4mm, 6mm, 8mm, 12mm etc, the length of final pellet and voltage can be customized.

Packing Details: By wooden/Iron sheet box or in container.

Delivery time: Within 10-15 working days.

Enjoy the way to design your own pellet production line.