Model:feeding screw conveyor

Diameter: 219mm/ 165mm

Length: 2.8m / 3.2m/ 3.8m

Founcation: All dosed materials will be fed into ribbon mixer by it ; underground installation design is more easily for your workers feeding materials.

- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

8 TON

-

Weight (KG):

-

1000 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KEDA

-

Voltage:

-

220V/380V, can bu customized

-

Dimension(L*W*H):

-

can be customized

-

Power (kW):

-

30 kW

-

Product name:

-

Dry powder complete equipment

-

Application scope:

-

power

-

Machine Type:

-

Industiral Blender Mixer Machine

-

Type:

-

Blending Vessels

-

Usage:

-

dry mortar,powder,cemen

-

Capacity:

-

2-8 ton per hour

-

Function:

-

Mixing Cement, powder,mortar,sand

Quick Details

-

Barrel Volume (L):

-

5000

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

0 - 28 r.p.m

-

Max. Loading Capacity:

-

8 TON

-

Weight (KG):

-

1000 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KEDA

-

Voltage:

-

220V/380V, can bu customized

-

Dimension(L*W*H):

-

can be customized

-

Power (kW):

-

30 kW

-

Product name:

-

Dry powder complete equipment

-

Application scope:

-

power

-

Machine Type:

-

Industiral Blender Mixer Machine

-

Type:

-

Blending Vessels

-

Usage:

-

dry mortar,powder,cemen

-

Capacity:

-

2-8 ton per hour

-

Function:

-

Mixing Cement, powder,mortar,sand

Product Introduction:

Simple dry powder mortar equipment is developed by our company specializes in special dry mortar equipment in the small equipment. The material is mixed twice and the dispersion is better. Dry mortar equipment and other equipment compared to the following advantages.

1. Dry powder mortar equipment, good dispersion: dry mortar mixer internal use of a unique structural design, can effectively disperse polypropylene fiber and wood fiber, completely solve the different proportion of the material caused by the separation and fiber reunion and other issues The

2. Dry mortar equipment use a wide range: dry mortar equipment to meet the different performance requirements of the production of dry mortar needs. Such as: masonry mortar. Plastering mortar. Insulation system required mortar. Decorative mortar and other dry mortar.

3. Dry powder mortar equipment Cost-effective: dry mortar equipment has a clear price advantage, for the external wall insulation and decorative mortar production projects, not only less investment, high efficiency, and to avoid the investment caused by excessive equipment idle and waste of resources.

4. Dry powder mortar equipment is simple and convenient: dry mortar equipment with small footprint, low energy consumption, easy operation, no basis can be installed directly using the advantages of production per hour 2-8 tons, operating workers 2-6 people You can.

|

Model

|

Out put

|

Occupied area

|

Equipment height

|

Batching and packaging

|

|

Simple type

|

3-4t/h

|

20m2

|

3-4m

|

Manual batching

Automatic packaging

|

|

Semi-automatic type

|

5-8t/h

|

50-60m2

|

6-7m

|

Manual batching Automatic packaging

|

|

Full automatic type

|

8-30t/h

|

60-65m2

|

7-8m

|

Automatic batching Automatic packaging

|

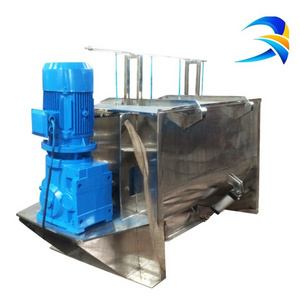

Main Features

1.A horizontal cylinder structure; Smooth operation, Low noise, Long service life, Easy installation.

2.Three-tier screw belt and three strands of material interpenetrate

Mix in the process of convection; And the bucket wall with no mess and no dead angle; Fast mixing speed and evenness;

3.Equipped with screw elevator;Feeding bucket is parallel to floor and it is easy to feed;

4.The horizontal body is equipped with a door, It is easy to clean.

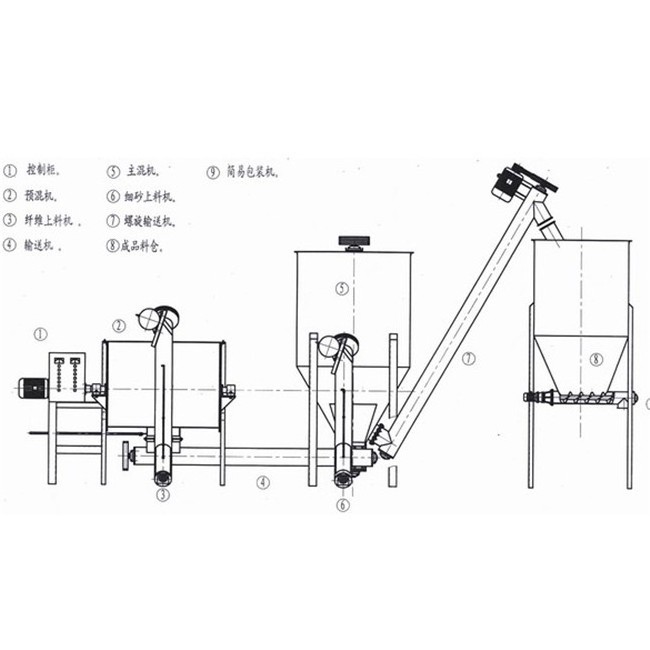

Working principle full automatic dry mortar complete equipment:

According to requirements of the customers, the system can be equipped with 3-6 bulk storage bins, the material in which will, after being processed by the metering and batching system, be conveyed to pending-for-mixing bin, and then fed into the high-efficiency biaxial agravic mixer for continuous mixing. The finished product in conformity with mixing accuracy requirements can be sent to the finished products bin shortly after mixed. Moreover, there is design with automatic rationing and packaging machine at the bottom of finished products bin, allowing for synchronous auto-packaging operation. Featured with easy and convenient operation, high efficiency, it can both obviously reduce labor intensity and effectively reduce dust pollution.

Descriptions of full automatic dry mortar complete equipment:

Full automatic dry mortar complete equipment is based on the latest design concept in Europe, this production adopts the advanced computer auto-control system, whose production capacity can reach 30-100 thousand tons per year depend on the system configuration. The production line consists of storage system, metering and batching system, conveying system, mixing system, air compressor system , packaging system, and dedusting system, etc

Application of full automatic dry mortar complete equipment

:

Full atuomatic dry mortar complete equipment can manufacture the following various mortars:

1) Masonry mortar 2) Thin and smooth wall morta 3) Hand-plastering screeding mortar 4) Colored coating mortar

Feeding System

Main Features of Mixing System

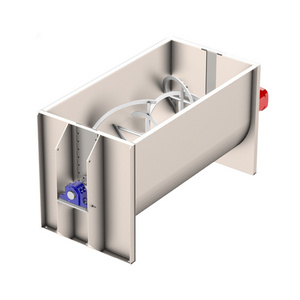

Model:Ribbon Mixer

Mixing Time : 3-5 min / batch

Thickness of ribbons: 6-8mm

Founcation: This mixer is very suitable for mixing the material which is temperature sensitive.

Due to the rotate speed, and the mixing uniform of it can meet 98% within 3 minutes.

Discharging System

Model: feeding screw conveyor

Diameter: 219mm/ 165mm

Length: 2.8m / 3.2m/ 3.8m

Founcation:The mixed products be conveyed into final products storage bin from the mixer by it.

Impeller Pallde Packing Machine

Weighing Scope:10-50kg,adjustance on panel.

Discharge Port Qty: 1pic

Capacity: 5-8t/h

Motor Powder: 3kw

Weighing device: Automatically

Advantages:

1.Fast packing,Easy to operate

2.No need for secondary sealing

3.Long-term work,good reliability