- Product Details

- {{item.text}}

Quick Details

-

Feature:

-

Moisture Proof

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Hongyan

-

Model Number:

-

SFMINI2024052913

-

length:

-

366M

-

Width:

-

100mm, 500mm or as per customer required

-

Product name:

-

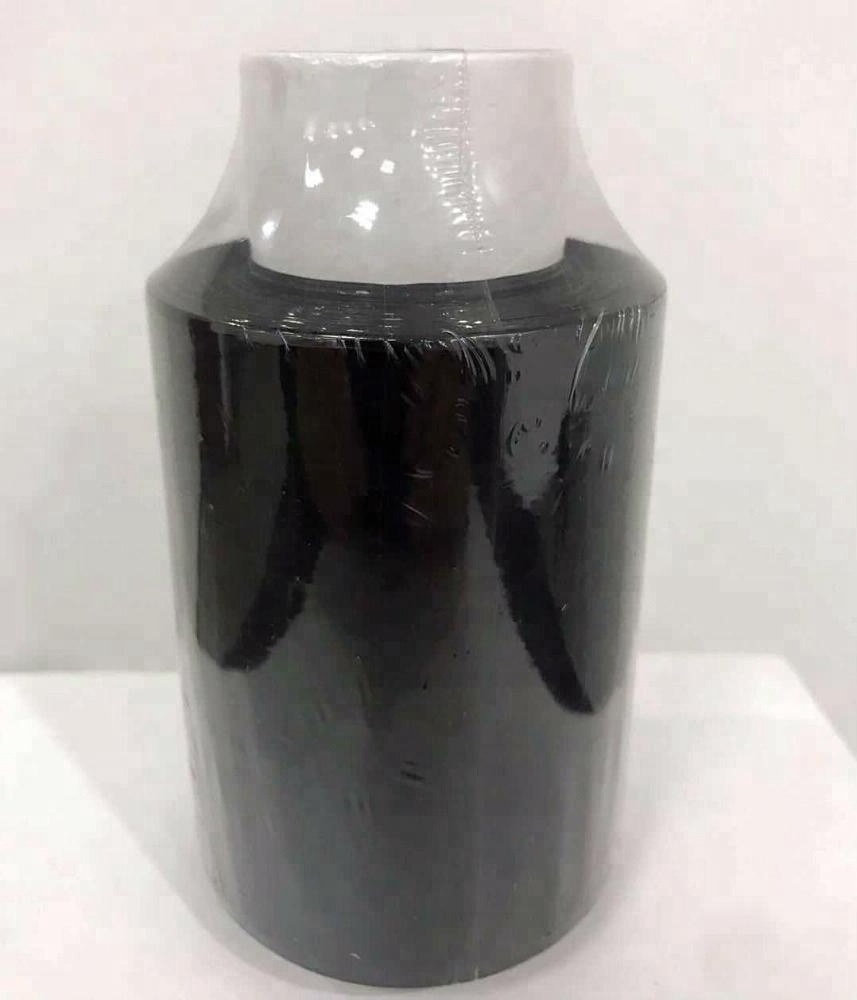

LLDPE Stretch Film

-

Multiple Extrusion:

-

5~7 layers

-

Color:

-

Transaprent or can be customized

-

Application:

-

Package

-

Packing:

-

24 rolls/carton

-

Item:

-

Roll Film

-

Sample:

-

Available(free Sample)

-

Port:

-

Ningbo/Shanghai

-

Certificate:

-

ISO9001, ISO45001, ISO14001

Quick Details

-

Material:

-

Lldpe

-

Type:

-

Stretch Film

-

Use:

-

Packaging Film

-

Feature:

-

Moisture Proof

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Hongyan

-

Model Number:

-

SFMINI2024052913

-

length:

-

366M

-

Width:

-

100mm, 500mm or as per customer required

-

Product name:

-

LLDPE Stretch Film

-

Multiple Extrusion:

-

5~7 layers

-

Color:

-

Transaprent or can be customized

-

Application:

-

Package

-

Packing:

-

24 rolls/carton

-

Item:

-

Roll Film

-

Sample:

-

Available(free Sample)

-

Port:

-

Ningbo/Shanghai

-

Certificate:

-

ISO9001, ISO45001, ISO14001

Products Description

Commonly physical properties of stretch film

|

Test item

|

Unit

|

Test method

|

|

Hand-wrap

|

Machine-wrap

|

Pre-stretch wrap

|

|

|

Thickness

|

μ

|

Thickness Gauge

|

|

9-25

|

9-30

|

12-30

|

|

|

Haze

|

%

|

ASTM D1003

|

|

1.2

|

1.2

|

1.2

|

|

|

Gloss60℃ angle

|

%

|

ASTM D523

|

|

86

|

86

|

90

|

|

|

Tensile strength

|

Kg/C㎡

|

ASTM D882

|

MD

|

280↑

|

350↑

|

350↑

|

|

|

|

|

|

TD

|

200↑

|

200↑

|

200↑

|

|

|

Elongation

|

%

|

ASTM D882

|

MD

|

400↑

|

400↑

|

500↑

|

|

|

|

|

|

TD

|

600↑

|

650↑

|

700↑

|

|

|

Tear resistance

|

Kg/cmv

|

ASTM D1922

|

MD

|

60↑

|

90↑

|

120↑

|

|

|

|

|

|

TD

|

120↑

|

150↑

|

200↑

|

|

|

Pre-stretch ratio

|

%

|

ASTEM D4649

|

|

-------

|

-------

|

200↑

|

|

|

Cling force

|

g/25cm

|

SWANSON

|

|

20-50

|

30-60

|

40-70

|

|

Note: Special requirements can be customized according to customer requirements.

Machine Use Stretch Film

The winding film is made from LLDPE and metallocene raw materials produced by ExxonMobil Chemical, Dow Dow Chemical, etc. The film has the advantages of high tensile strength, high shrinkage, high puncture resistance, high transparency and high tear strength.

Hand Use Stretch Film

Hand Use Stretch Film is a film made of imported LLDPE raw material with high transparency, high elongation and strong puncture resistance, which is suitable for wrapping outside the pallet and wrapping of scattered and semi-finished goods inside the factory.

Slitting Stretch Film(Mini Stretch)

Slitting film, also called mini film, is commonly used in the width range of 4-30cm, which is generally customized according to customer requirements and can be used with movable handles, paper tube extensions and other methods of packaging.

Features & Benefits

Selection of the world's most advanced seven-layer co-extruded film unit

Seven-layer co-extruded film has the characteristics of :

1, high barrier: the use of different plastic materials barrier properties vary greatly, co-extruded film, to achieve a high barrier to oxygen, water, carbon dioxide, odours and other effects.

2, strong function: oil resistance, moisture resistance, resistance to low temperature freezing, preservation of quality, freshness, odour, can be used for vacuum packaging, aseptic packaging, inflatable packaging.

3, low cost: relative to glass packaging, aluminium foil packaging and other plastic packaging, to achieve the same barrier effect, co-extruded film has a greater advantage in cost.

Because of the simple workmanship, the production of film product costs and dry composite film and other composite films can be reduced by 10-20%.

Imported raw materials(LLDEP)

Our company uses imported linear low density polyethylene (LLDPE) raw materials from ExxonMobil Chemical, Chemical, Dow Dow Chemical and other companies to produce our wrap films. Imported LLDPE raw materials have higher quality standards and more stringent production processes, resulting in higher reliability and durability of our products. In addition, the use of high quality imported raw materials also improves production efficiency and product performance.

Thinner thickness

Our company uses an advanced process to produce a thinner, stronger and more transparent wrap-around film. Compared to traditional wrap films, our products are more environmentally friendly, in addition to saving costs and improving wrapability and stability.

Use for a wide range of applications

Our wrap films are divided into various models according to different usage scenarios and needs, which are suitable for packaging and protecting goods in various fields. Whether you are transporting food, beverages, cosmetics, or need to wrap furniture, machinery and equipment, or electronic products, we can provide the most suitable wrap film products and customized solutions for you.

Standardized quality management system

Our company has always attached great importance to the control of product quality, and therefore has established a strict production management process. We have adopted strict standards and procedures for our production process from raw material procurement, production processing, to quality inspection of finished products. Each batch of products is inspected and tested several times to ensure that it meets our high quality standards.

Packaging & Shipping

Our company offers a wide range of different wrap-around film packaging specifications based on different sizes and applications in order to better meet our customers' needs. We are also able to customize packaging and branding to ensure the integrity and quality stability of our products during transportation and use. We are committed to providing our customers with a full range of services and support to ensure that they receive the best wrap film product for their needs. Whether you need to purchase in bulk or customize, we can provide you with a satisfactory solution.

Certifications

Hot Searches