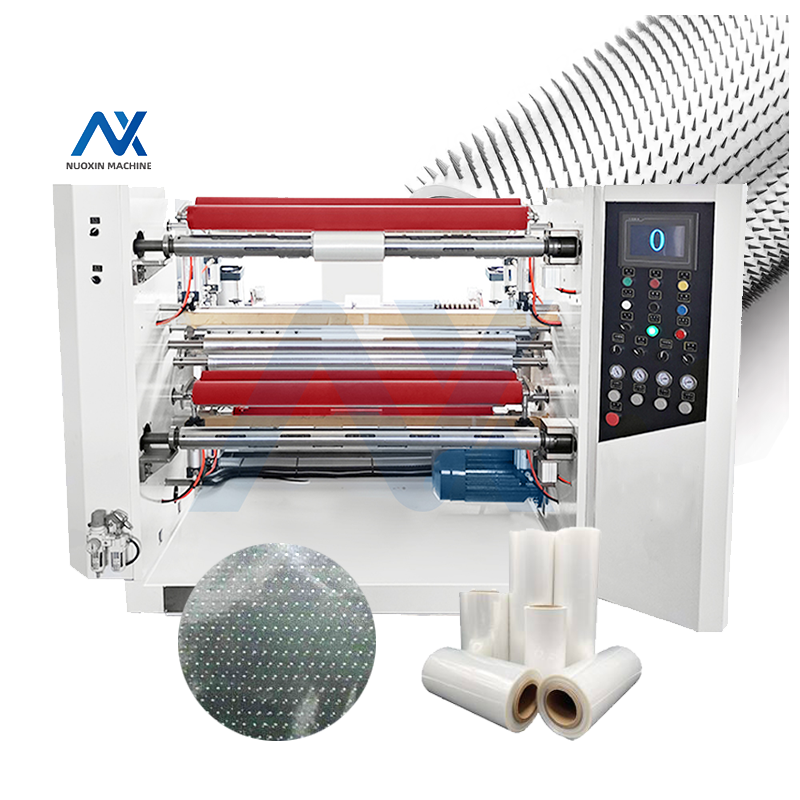

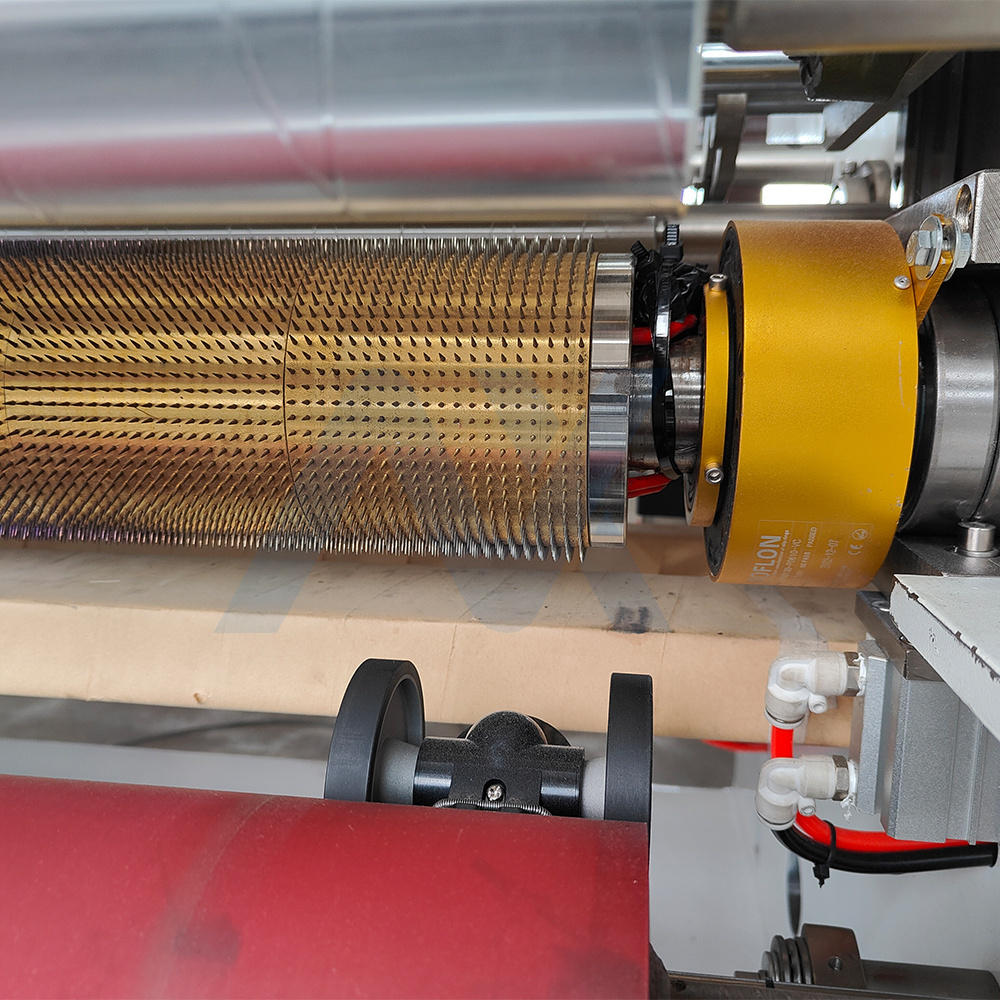

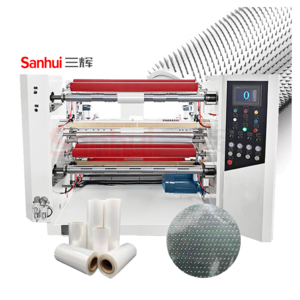

1.This machine equipped with a heatable micro perforating roller and a special brush-type pressure roller to make pinhole in the

materials

2.The Plastic PE PP Film with pinhole is widely used in packaging films such as bread, food, flowers and other industrial

perforated breathable products covering the field of film perforation in many industries.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Weight:

-

2600 kg

-

Machine Model:

-

DBWSFQ200-1350

-

Max. Unwinding material width:

-

1350mm

-

Maximum Unwind Diameter:

-

1200mm

-

Slitting width:

-

50mm-1300mm

-

Slitting speed:

-

10-200m/min

-

Max. Rewinding dia:

-

600mm

-

Machine size (mm) L*W*H:

-

3190*2370*1420

-

Thickness of slit material:

-

20-500g/m²

-

Slitting precision:

-

±0.1mm

-

Maximum rewinding diameter:

-

600mm

Quick Details

-

Type:

-

Slitting Rewinder

-

Production Capacity:

-

200 m/min

-

Max. workable width:

-

1350mm

-

Place of Origin:

-

Zhejiang, China

-

Weight:

-

2600 kg

-

Machine Model:

-

DBWSFQ200-1350

-

Max. Unwinding material width:

-

1350mm

-

Maximum Unwind Diameter:

-

1200mm

-

Slitting width:

-

50mm-1300mm

-

Slitting speed:

-

10-200m/min

-

Max. Rewinding dia:

-

600mm

-

Machine size (mm) L*W*H:

-

3190*2370*1420

-

Thickness of slit material:

-

20-500g/m²

-

Slitting precision:

-

±0.1mm

-

Maximum rewinding diameter:

-

600mm

Products Description

Introduction

The whole machine frame is made of iron plate, with extremely high precision and stability.

Application

The machine is suitable for slitting rewind all kinds of film PP,PE,PVC shrink film...etc.

Machine Feature

1.The whole machine is driving by Double servomotor.

2.Photoelectric EPC system.

3.Automatic constant tension of unwinding and rewinding by magnetic powder brake and clutch.

4.Rewinding and unwinding adopts air shaft.

5.Guide roller is plated with hard chromium, which makes the guide roller hard, wear-resistant, mild and corrosion-resistant.

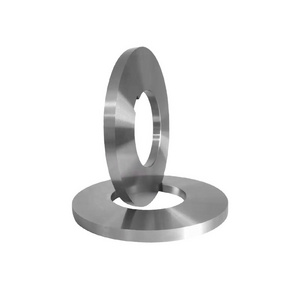

6. The standard machine equipped with 1 set(10 pcs)straight knife , circular knivesis optional.

7. The machine has the auto functions like automatic counting meter, emergency stop, alarm etc.

|

Slitting speed

|

10-200m/min

|

|

Maximum material width

|

50-1350mm

|

|

Slitting width

|

20-1350mm

|

|

Thickness of slit material

|

20-500g/m²

|

|

Slitting precision

|

±0.1mm

|

|

Maximum Unwind Diameter

|

1200mm

|

|

Maximum rewinding diameter

|

600mm

|

|

Deskewing method

|

CCD

|

|

Tension control mode

|

PLC控制

|

|

Total power (KW)

|

9KW

|

|

Machine weight

|

2600kg

|

|

Total power

|

17KW

|

|

Machine size (mm) L×W×H

|

3190*2370*1420

|

Machine Details

1 Unwinding Unit

1.Pneumatic cylinder auto loading,easy to lift heavier roll

2.unwinding is controlled by magnetic powder brake

3.unwinding adopts air shaft.

2 Arise correction EPC

1.Unwinding edge position control adopts Photoelectric EPC system

3 Traction and Driving Unit

1.Guide roller is plated with hard chromium, which makes the guide roller hard, wear-resistant, mild and corrosion-resistant.

2.The whole machine is driving by 2 servo motors

4 Slitting Unit

1.This machine is equipped with 1 set Straight knives,and the knife holder adopts safety protective cover

5 Rewinding Unit

1.Rewinding is controlled by magnetic powder brake

2.Two rewinding roller,and rewinding adopts air shaft.

3.Single side swing discharging way

2.Two rewinding roller,and rewinding adopts air shaft.

3.Single side swing discharging way

6 Control Panel

1.PLC+Touch screen,easy to operate

2.The machine has the auto functions like automatic counting meter, emergency stop, alarm etc.

2.The machine has the auto functions like automatic counting meter, emergency stop, alarm etc.

Contact Us

Packing & Delivery

Hot Searches