- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GAOQI

-

Dimension(L*W*H):

-

6500*2450*2200mm

-

Weight:

-

4500 KG

-

After-sales Service Provided:

-

Overseas third-party support available

-

Color:

-

Luxury Gold/Customized

-

Product name:

-

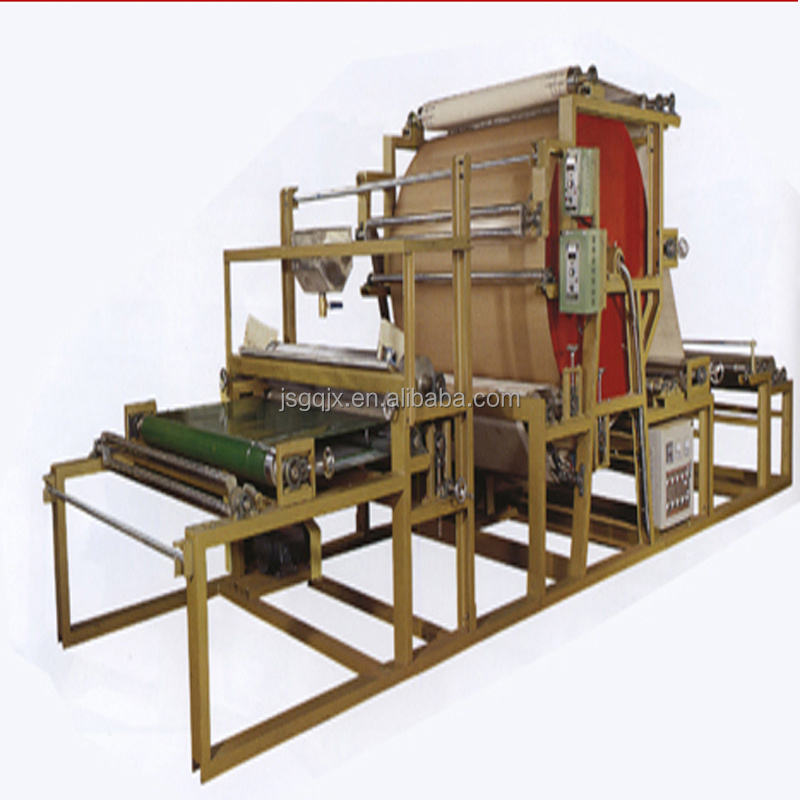

Sheet Laminating Machine

-

Base Material:

-

Sponge,XPE,PVC,EVA,SBR,cloth, leather,high foaming and other materials

-

Max laminating width:

-

1500mm/Customized

-

Machine Desigened Speed:

-

5-45m/min

-

After Warranty Service:

-

Online support

-

Marketing Type:

-

New Product 2022

Quick Details

-

Packaging Type:

-

Film

-

Packaging Material:

-

Plastic, Wood

-

Driven Type:

-

Electric

-

Voltage:

-

380V/50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GAOQI

-

Dimension(L*W*H):

-

6500*2450*2200mm

-

Weight:

-

4500 KG

-

After-sales Service Provided:

-

Overseas third-party support available

-

Color:

-

Luxury Gold/Customized

-

Product name:

-

Sheet Laminating Machine

-

Base Material:

-

Sponge,XPE,PVC,EVA,SBR,cloth, leather,high foaming and other materials

-

Max laminating width:

-

1500mm/Customized

-

Machine Desigened Speed:

-

5-45m/min

-

After Warranty Service:

-

Online support

-

Marketing Type:

-

New Product 2022

OUR FACTORY

PRODUCT PARAMENTERS

Product

EVA fabric laminating machine with super glue

EVA fabric laminating machine with super glue

Mainly used for laminating with sponge, XPE, PVC, EVA, SBR, cloth, leather, high foam and other materials, using strong adhesive as bonding material, especially specializing in laminating with PVC, EVA, SBR, carpet of square piece of material. Widely apply for shoe-making, carpet, diving clothing, toy, handbag, luggage & bag, cushion, mouse pad and other industries.

Features:

1.Both sheet materials and coil materials are automatically feeding and glueing with conveyer belt,and high-temperature wool belt

pressed to make the finished product more firm and smooth, no indentation.

2.Manual or pneumatic regulation can be used on the gluing wheel.

3.Glue adjustment using high precision high fine adjustment seat to ensure glue precision.

4.Wool belt / PVC belt can be optional according to your needs.

1.Both sheet materials and coil materials are automatically feeding and glueing with conveyer belt,and high-temperature wool belt

pressed to make the finished product more firm and smooth, no indentation.

2.Manual or pneumatic regulation can be used on the gluing wheel.

3.Glue adjustment using high precision high fine adjustment seat to ensure glue precision.

4.Wool belt / PVC belt can be optional according to your needs.

|

Voltage

|

380V 50HZ 3Phase

|

|

Effective material width

|

1500mm/ customized

|

|

Heating method

|

electric / heat conduction oil / gas /steam

|

|

Big cylinder diameter

|

1200mm / 1500mm /1800 mm /customized

|

|

Heating power

|

about 40.5KW

|

|

Machine roller width

|

1800mm / customized

|

|

Coating method

|

scraping

|

|

Machine power

|

about 50 KW

|

|

Machine designed speed

|

5-45 m/min

|

|

Overall dimension(L*W*H)

|

about 6500*2450*2200mm

|

CUSTOMER VISIT

OUR HOT SALES

CONTACT INFO

FAQ

Hot Searches