- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

RZ

-

Model Number:

-

Ceramics Inserts

-

Product name:

-

Ceramic Cutting Tools

-

Application:

-

Auto parts,Bearing,machinery, metallurgy, mining, railway locomotive

-

Material:

-

silicon nitride ceramic

-

Type:

-

Turning Inserts

-

Workpiece:

-

cast iron,Hard Steel,Super Alloys

-

Package:

-

Standard Package

-

Tool type:

-

CNC turning tool

-

Advantage:

-

Longer Working Life

-

MOQ:

-

10 Pieces

-

Feature:

-

Hign Wear Resistance

Quick Details

-

Use:

-

Turning Tool

-

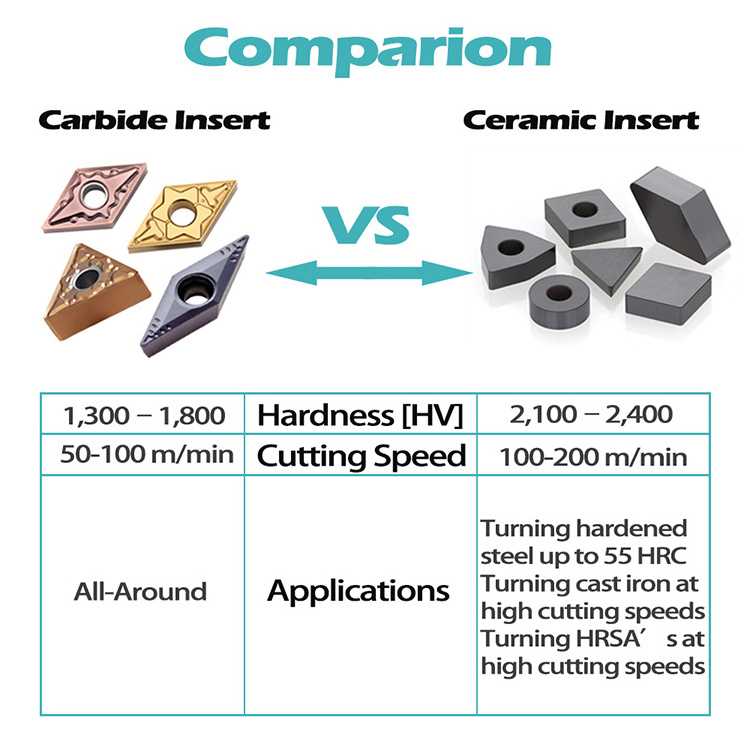

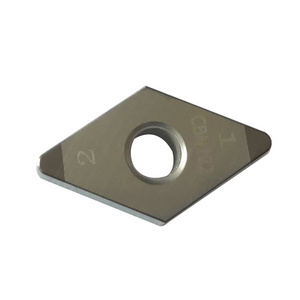

Hardness:

-

HV 2,100-2,400

-

Coating:

-

Uncoated

-

Place of Origin:

-

China

-

Brand Name:

-

RZ

-

Model Number:

-

Ceramics Inserts

-

Product name:

-

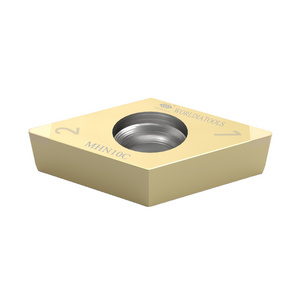

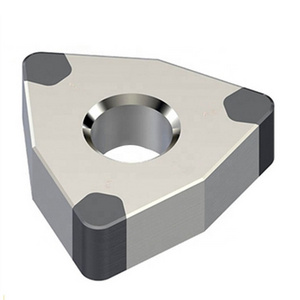

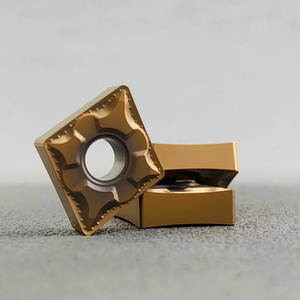

Ceramic Cutting Tools

-

Application:

-

Auto parts,Bearing,machinery, metallurgy, mining, railway locomotive

-

Material:

-

silicon nitride ceramic

-

Type:

-

Turning Inserts

-

Workpiece:

-

cast iron,Hard Steel,Super Alloys

-

Package:

-

Standard Package

-

Tool type:

-

CNC turning tool

-

Advantage:

-

Longer Working Life

-

MOQ:

-

10 Pieces

-

Feature:

-

Hign Wear Resistance

Related Products

Products Description

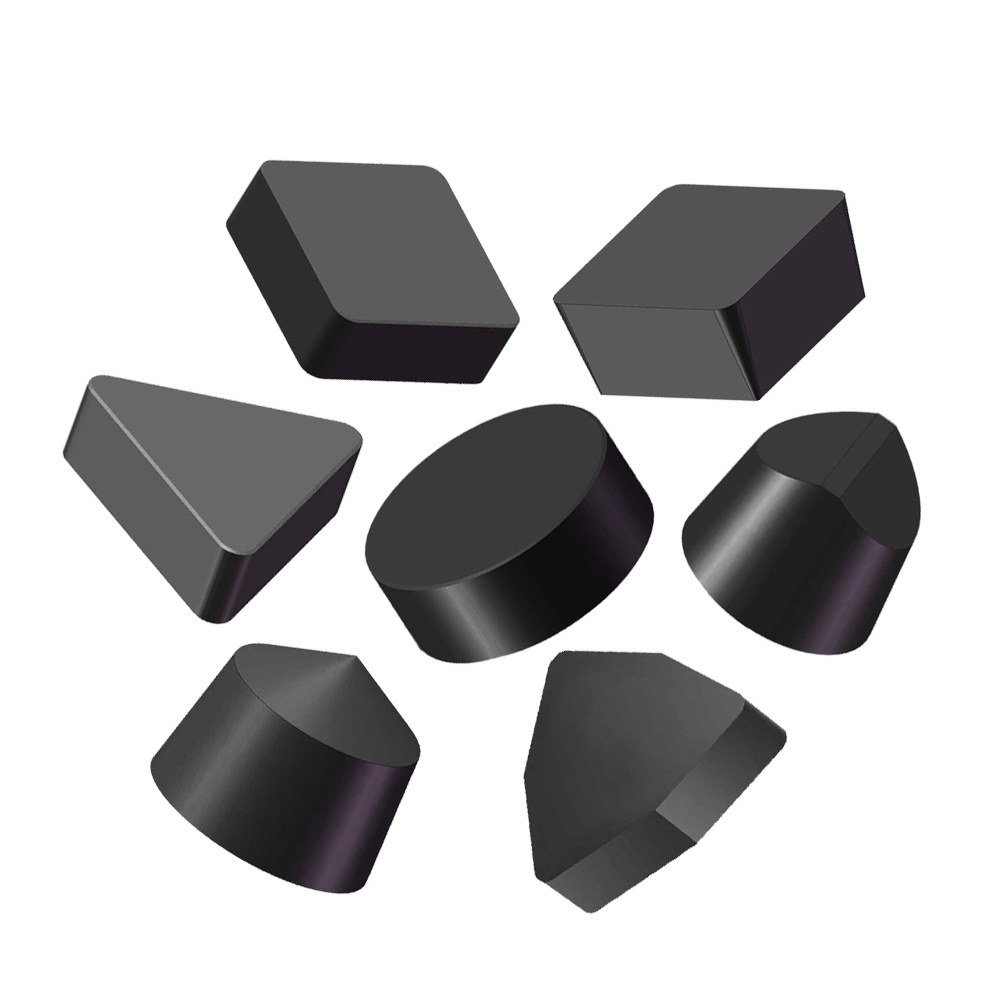

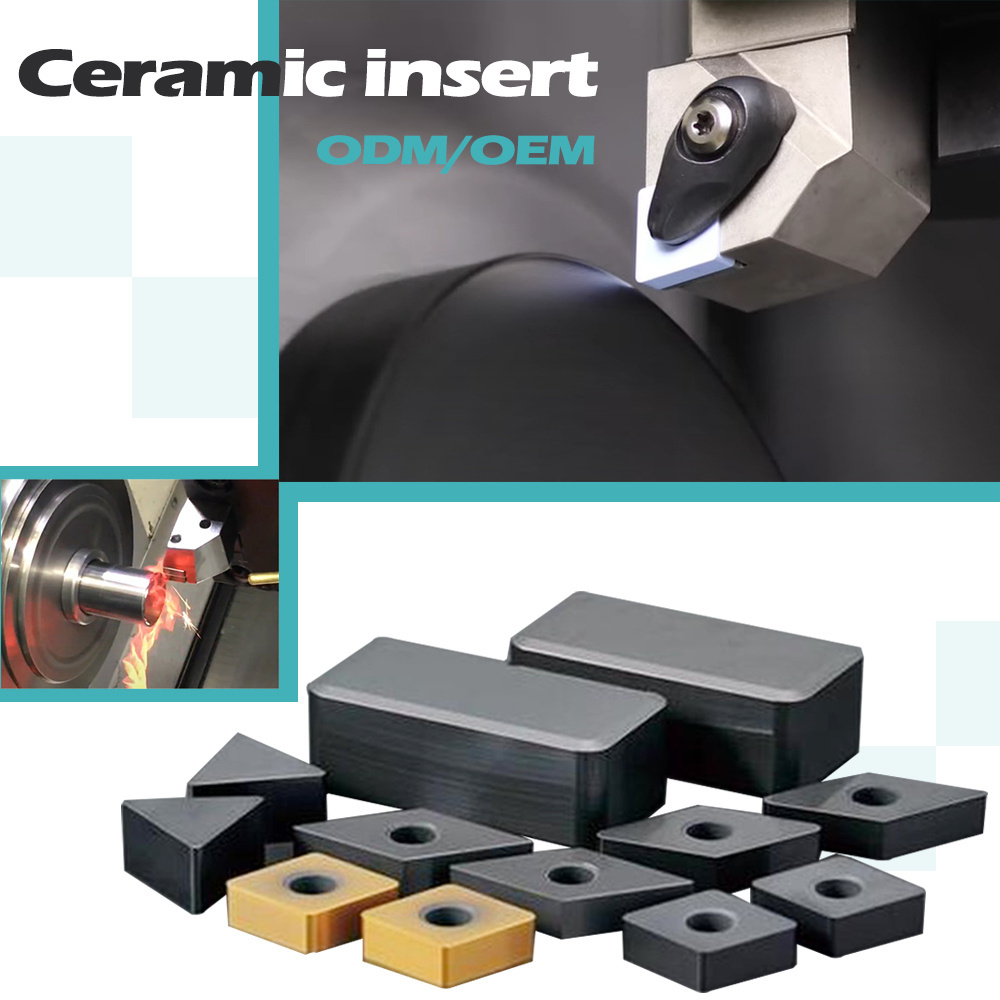

Ceramic Tool

Ceramic grade tools are typically classified into three general categories: oxide, nitride, and matrix ceramics.

Oxide ceramics are alumina-based and are generally used in roughing and finishing applications of the cast and gray irons. Increasingly, oxide ceramics are being used in dry machining applications at high speeds. This is due to the advancements within materials science, including the incorporation of whisker-based materials.

Nitride ceramics exhibit extremely high fracture toughness and are used for roughing and semi-roughing of cast irons under harsh conditions, such as when there is considerable starting and stopping that would typically increase fracturing.

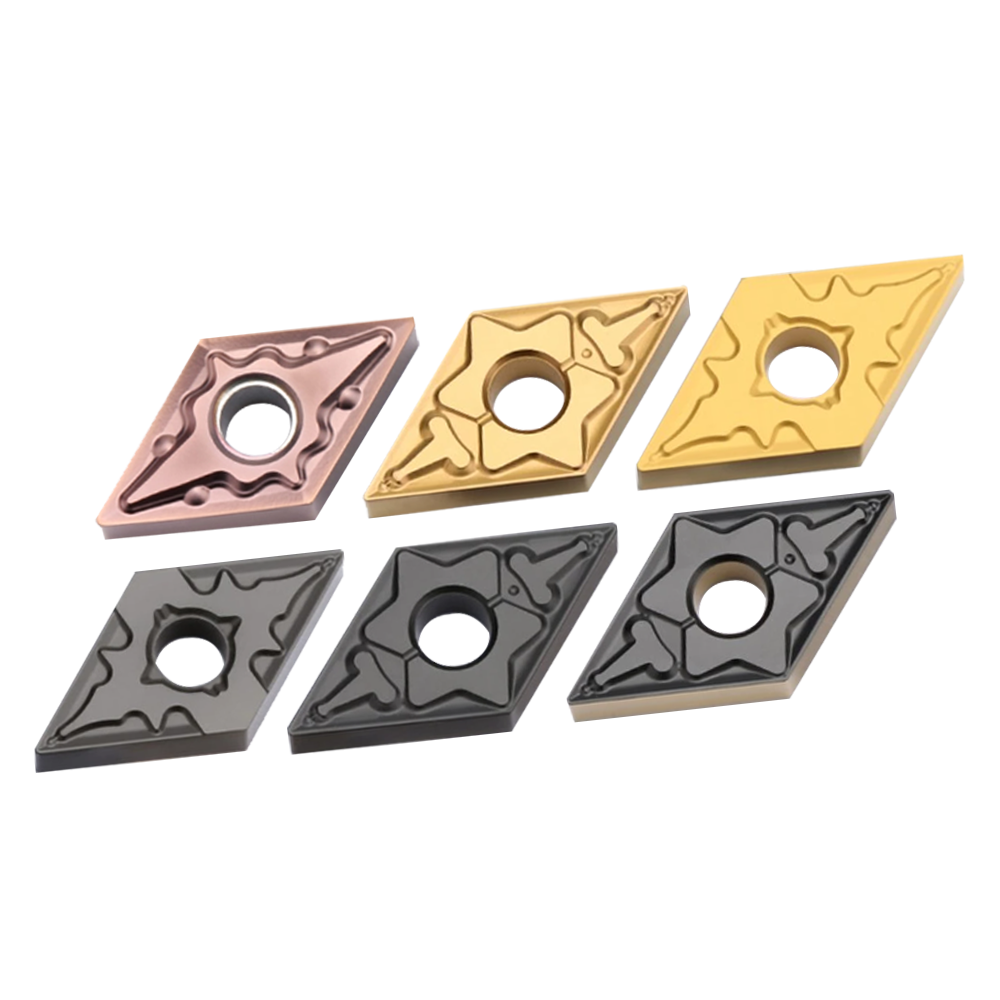

Ceramic inserts are divided into several sub-types (See below chart):

|

NAME

|

COLOR

|

COMPOSITION

|

APPLICATIONS

|

|

Silicon Nitride

|

Grey

|

Silicon Nitride (Si3N4)

|

Used for roughing and finishing applications in grey cast iron.

|

|

White Ceramics

|

White

|

Aluminum Oxide (Al2O3)

|

Used for roughing and finishing applications in alloyed cast iron.

|

|

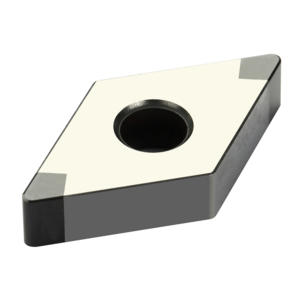

Black / Mixed Ceramics

|

Black

|

Aluminum Oxide (Al2O3) with Titanium

|

Finishing applications on Hard Steel and Cast Iron

|

|

Sialon

|

Grey

|

α and β SiAlON

|

Used for turning Nickel-Based alloys at very high cutting Speeds. Provide slightly lower performance when compared to Whiskers but

at a much lower price |

|

Whiskers

|

Green

|

silicon carbide whiskers (SiCw)

|

Extreme toughness. Used for turning Nickel-Based alloys at very high cutting Speeds

|

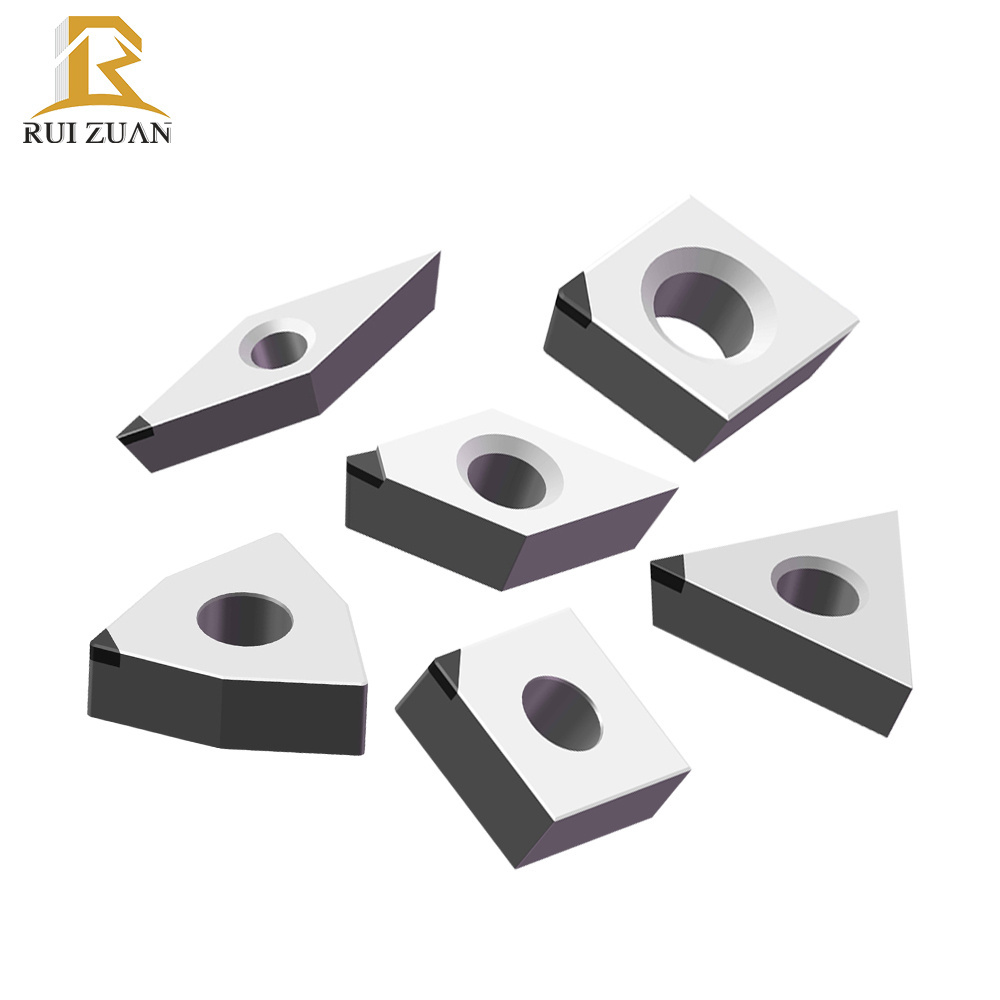

Advantages of silicon nitride ceramic cutting tools

● good wear resistance and can be used to process high hard materials

● It can be used for rough and finish machining of high hardness materials

● The silicon nitride ceramic blade has less friction with metal when cutting, which makes it difficult to stick to the blade

● The tool’s durability higher than that of traditional tools, which reduces the number of tool changes during machining

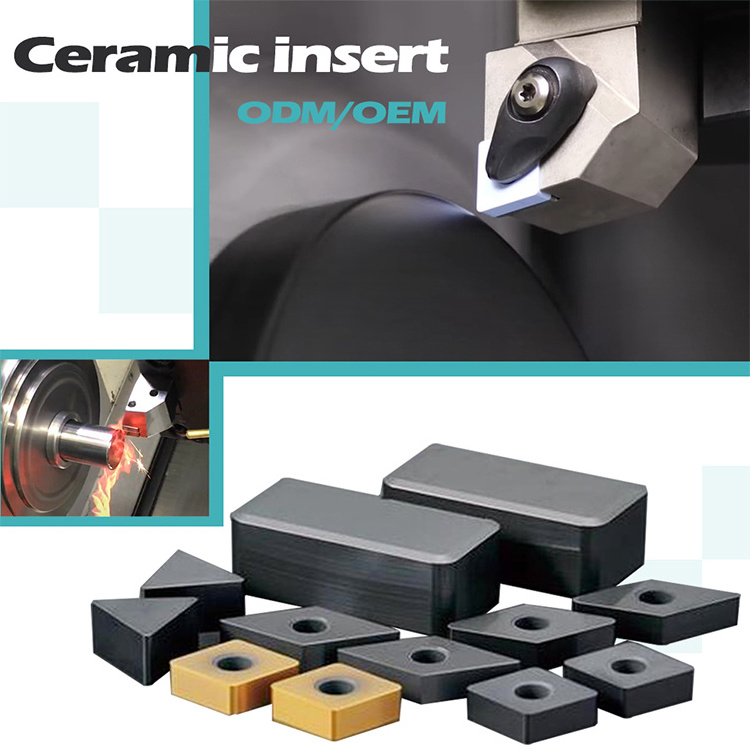

The main turning applications for Ceramics

Mainly used in

Auto parts processing,Bearing machining,Hard cast iron processing,

aerospace, precision instruments, molds, etc Machining Hard Steel, Machining Super Alloys

Other fields:machinery, metallurgy, mining, railway locomotive

Why Choose Us

Hot Searches