- Product Details

- {{item.text}}

Quick Details

-

Certification:

-

ISO9001:2008

Quick Details

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

No overseas service provided

-

Weight:

-

5-100tons

-

Certification:

-

ISO9001:2008

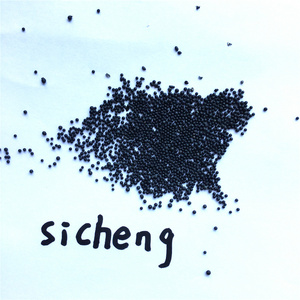

Resin coated sand for casting machinery foundry

We are a member od trade assurance system in alibaba.com

What is Trade Assurance?

Trade Assurance is a free payment protection service for buyers.

The service is offered by participating suppliers, and is designed to protect your payment if your order is not shipped on time, or if the pre-shipment product quality (optional) does not match the terms agreed on your contract.

Your payment is protected up to 100% of an amount - agreed between you and the supplier - called the Trade Assurance Order Amount.

How does it protect my order?

Alibaba.com will refund up to 100% of the Trade Assurance Order Amount on your contract if:

1.Your order is not shipped on time as stated in your contract.

2.Your products do not meet the quality requirementsstated in your contract.

The product quality must be checked before shipment.

This feature is optional. You must enable it when you place your order.

Resin sand casting process line is mixing the furan resin and sand together, then filling the mixed sands into the sand boxes, then after tamping, using the paints to flush the surfaces of molds, then burning the paints to make the sand molds to become very hard, finally, pouring the liquid iron into the solid sand molds.

This production line,to resin sand as material, use of molding machine making sand mould and pour molten iron in to sand mould,the last generate workpiece. The resin sand is mixed of natural silica sand, resin and hardener. The whole line compose of sand reclamation system and molding system. Sand reclamation system which is used sand after crushing, screening to use again. Molding system is put the mixture of resin sand fill in the molding machine, generate sand mould for pouring.

1. Material

The resin sand casting process mainly uses the resin sand as the molding material, and need to use the alcohol paints.

2 . Equipments

The resin sand casting process usually needs equipments to mix the resin sand and fill the sands into the sand boxes.

3. Production time

The resin sand casting process has an extra time to flush the paints, and burn the paints and wait the resin molds become hard.

4.Casting quality

The casting quality has big difference for these two processes. Since resin sand casting process uses the hard molds, therefore, resin sand castings have better surface smoothness, higher dimensional tolerance, and less surface and inside casting defects , such as sand holes, air holes and shrinkage.

5.Suitable casting products

Resin sand casting process is suitable to produce large iron castings with weight range from dozens of kilograms to several tons.

Technological process

Used-sand reclamation,Used-sand crushing regeneration, Used-sand magnetic separation, Used-sand screening,Used-sand air separation, Used-sand temperature adjustment,New&used sand conveying,Add resin or sodium silicate,etc,Mix sand,Making core,Molding,Pouring.

Main equipment of the production line

Shakeout machine,Vibrating conveyor,Belt conveyor,Pneumatic conveyor,Magnetic separator,Air seprator, Sand screening device, Bucket elevator,Chain elevator, Crusher,Sand reclamation device,sand temperature adjustment device,Cooler,Drying device, Electronic scale device,Continuous sand mixer,Molding machine,Dust collector,Electronic conrol system,etc.

Packing: Nude packing and bulk packing

Shipping: If our clients do not have a certain port, we recommend Qingdao.

1. We do not provide sample, because our products are machines which are large and complicated.

2. We do provide special service or customized service, we can design the layout of your workshop.

3. We can send out clients to your place to help your installation and debugging. Engineers are available to go abroad.