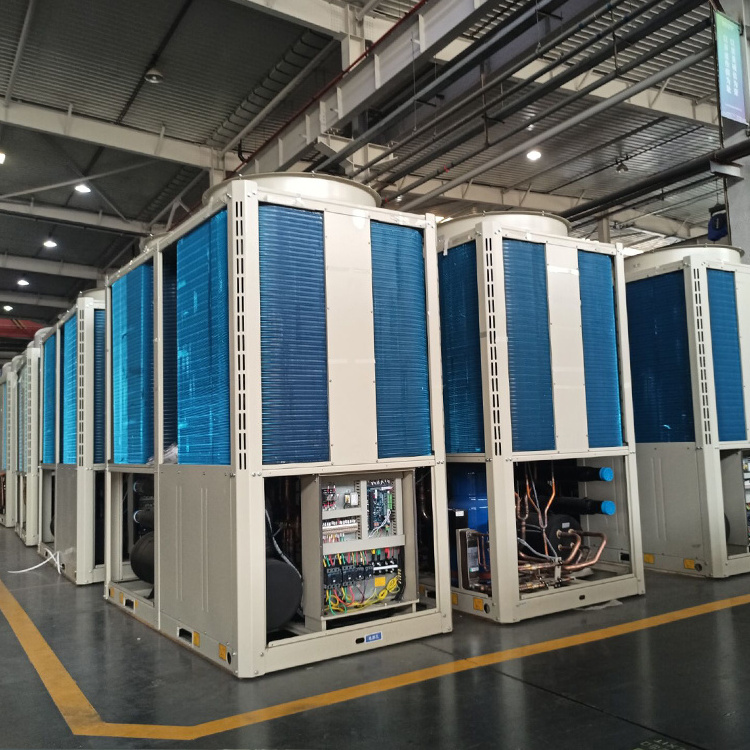

Modular design, and there is no need to distinguish between master and slave units when combining modules, which is convenient for

installation. The unit can control the main machine through the wire controller, and can expand up to 15set slave machines, which

can meet the load requirements of different buildings, and different series of models can be combined for joint control

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1810*960*2350 & 2011*1100*2300

-

Weight:

-

580 KG

-

Power:

-

65000

-

Working Temperature Range:

-

-20°C~48°C

-

Product Name:

-

Holtop Modular Air Cooled Chiller

-

Nominal Cooling capacity:

-

65~130KW

-

Nominal Heating capacity:

-

71~141KW

-

Refrigerant Type:

-

R410A

-

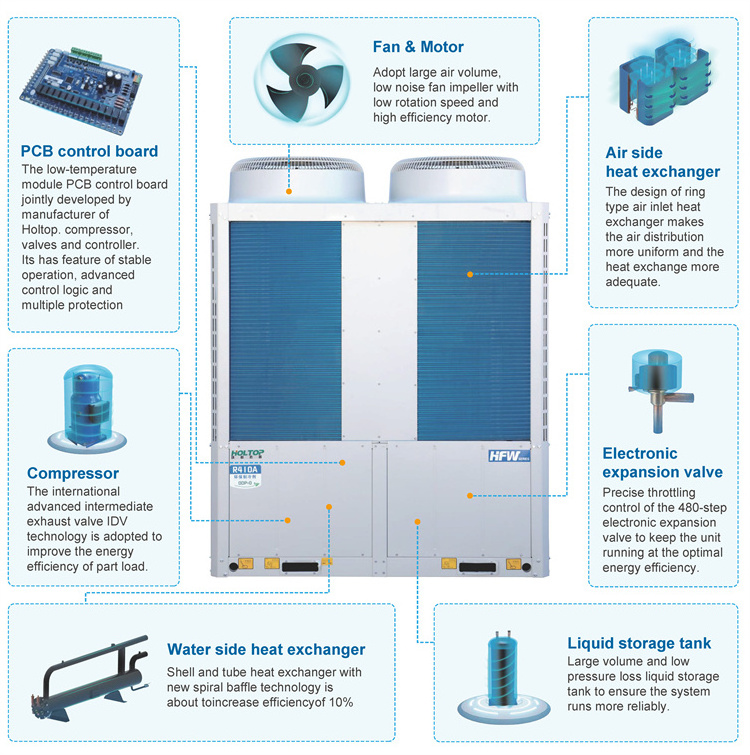

Compressor:

-

Hermetic Scroll Compressor

-

Fan:

-

Axial low noise fan

-

Throttle parts:

-

Electronic expansion valve

-

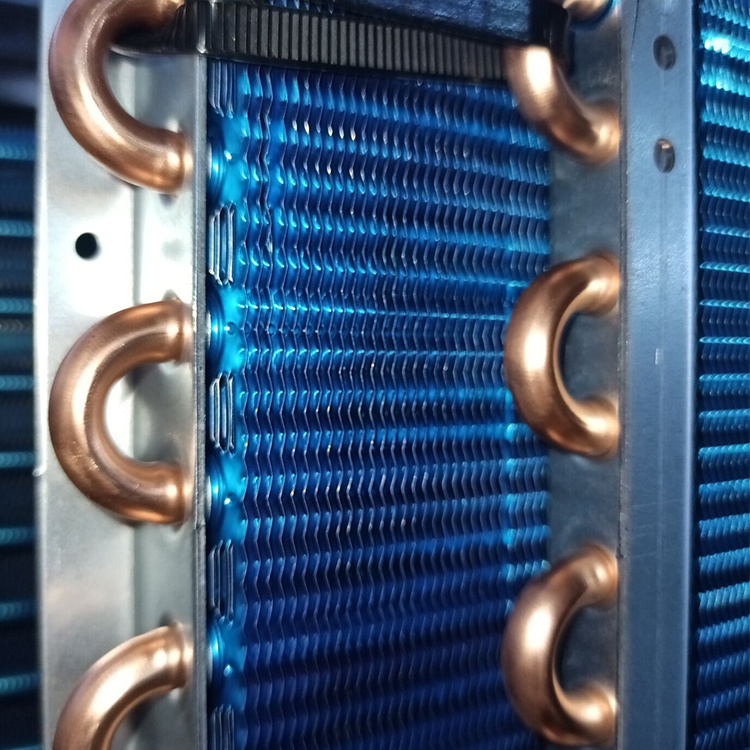

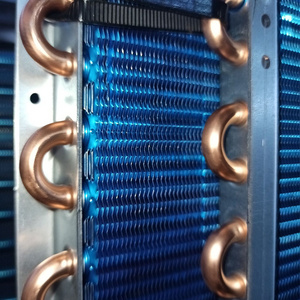

Airside heat exchanger:

-

Finned heat exchange

-

Waterside heat exchanger:

-

Shell&tube heat exchanger

-

Control System:

-

PLC Control System

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Holtop

-

Voltage:

-

330V

-

Dimension(L*W*H):

-

1810*960*2350 & 2011*1100*2300

-

Weight:

-

580 KG

-

Power:

-

65000

-

Working Temperature Range:

-

-20°C~48°C

-

Product Name:

-

Holtop Modular Air Cooled Chiller

-

Nominal Cooling capacity:

-

65~130KW

-

Nominal Heating capacity:

-

71~141KW

-

Refrigerant Type:

-

R410A

-

Compressor:

-

Hermetic Scroll Compressor

-

Fan:

-

Axial low noise fan

-

Throttle parts:

-

Electronic expansion valve

-

Airside heat exchanger:

-

Finned heat exchange

-

Waterside heat exchanger:

-

Shell&tube heat exchanger

-

Control System:

-

PLC Control System

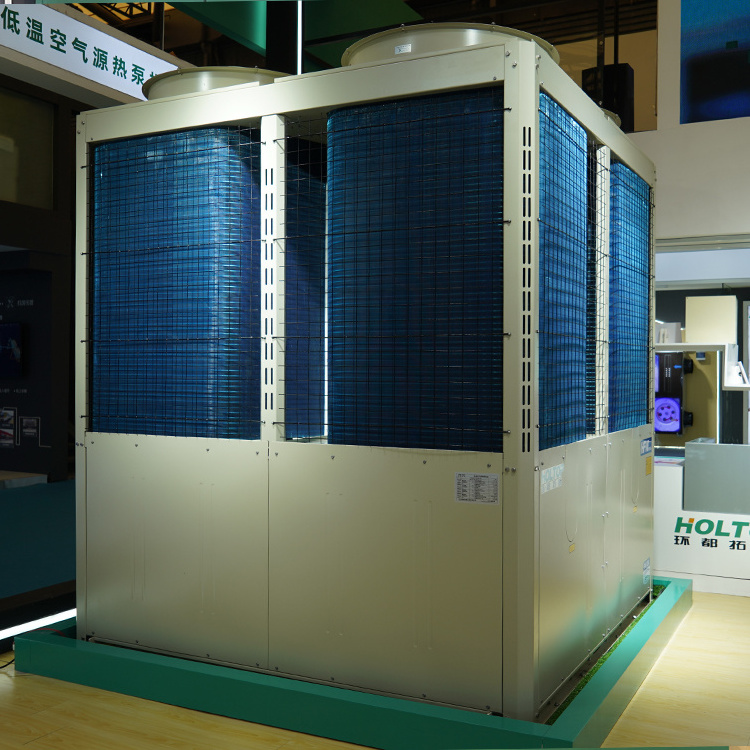

Product Description

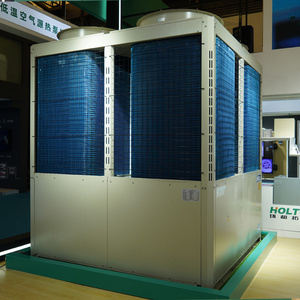

Modular Air Cooled Chiller (Heat Pump)

Holtop HFW series modular air cooled chiller (heat pump) is sophisticated design with fine and elegant configuration, flexible modularized structure. It can be adopted to all kinds of FCU, AHU indifferent specification. HFW series chiller (heat pump) own its feature of high efficiency, low noise, friendly HMI operation, stable and safe running, easy installation and maintenance. The unit canbe widely used for large or small-sized industrial and civil air conditioning project, like factories, station, hotels, villas, office building, high-end apartments etc.

Sophisticated Design

Holtop has accumulated years of tech nical experience in modular air cooled units, and has continuously launched new products of high efficiency and environmental , thus to build an energy-saving society. The modular air cooled chiller (heat pump) has reached the national second-level energy efficiency certification and obtained the national energy-saving product certificate.

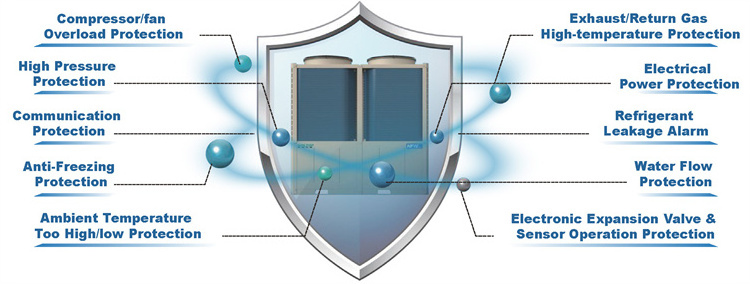

Integrated Protection

Integratedprotectionby more than10 protectionmeasures. and viamulti-variable monitoring of intelligent controller, toguarantee the stableand highefficiencyoperation

Double Anti-freezing protection

Water pump running anti-freezing

: In standby mode, if the system water temperature is too low, the unit will start the water pump for anti-freezing cycle;

Unit heating and anti-freezing

: When the water temperature exceeds the safety parameter, the unit starts the heating and

anti-freezing cycle until the water temperature rises to the preset safe value.

Failure Backup

One unit adopts a multi-compressor design. When one of the compressors fails, the rest of the compressors in the system can still operate normally without affecting the normal use of the entire system.

Module intelligent defrosting

Holtop air cooled heat pump, unit accurately judges the frosting situation through multi-variable parameters and enter the

defrosting mode intelligently, concentrate the heat of the system to melt the frost layer to the maximum extent, and shorten the defrosting time. Avoid problems such as insufficient defrosting or frequent defrosting. When heating in severe low temperature environment, manual forced defrosting can be set.

defrosting mode intelligently, concentrate the heat of the system to melt the frost layer to the maximum extent, and shorten the defrosting time. Avoid problems such as insufficient defrosting or frequent defrosting. When heating in severe low temperature environment, manual forced defrosting can be set.

The unit adopts a multi-compressor system, which can realize alternate defrosting; when multiple units are combined, the units are mutually backed up, and the units are defrosted at intervals. The number of defrosting systems does not exceed half of the total number of systems to ensure that the water temperature is stable to meet heating needs. Eliminate the phenomenon of indoor side blowing cold wind, to ensure the comfort of use

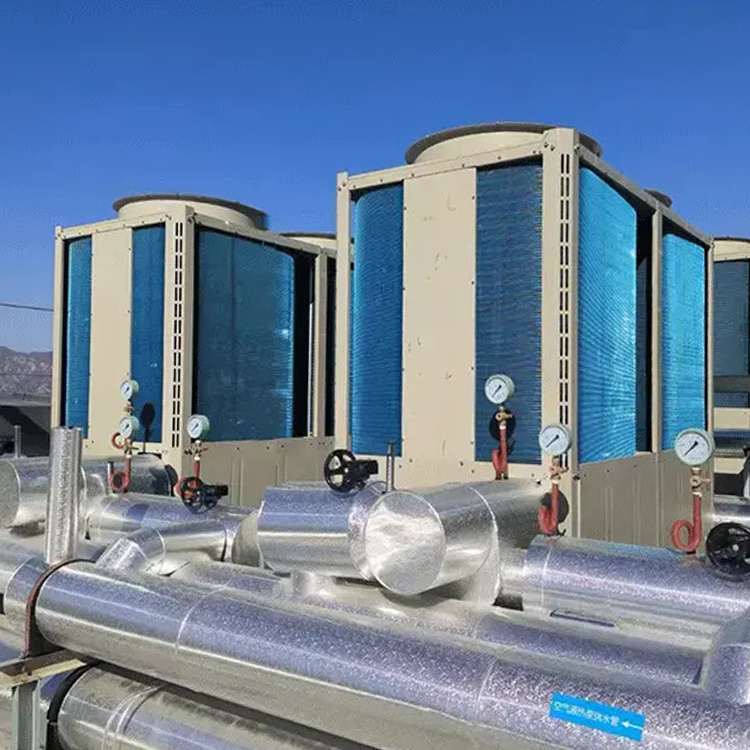

Modular Combination

Flexible Application

Investment

:

Flexible for further extension, lower investment ininitial project stage

Transportation

:

The unit is small in size and can be transported independently without large hoisting equipment.

Installation

:

Just install it in a well-ventilated place, no special machine room and cooling water system are required. The water inlet and outlet design at the end of the unit is more conducive to reducing the installation space on site.

System

:

In addition to the traditional constant water flow system, the terminal circulation system can also be designed as a primary pump variable water flow

Intelligent Control

Optional PLC control system

The PLC control system combines the simplicity and convenience of the wired control system and the advantages of centralized group control system to achieve chiller group centralized control. One PLC control system can manage 1 to 8 groups of air cooled chiller, each group can control 1 to 16 pieces of modular chillers, that is, 128 modular chillers at most. The control system can deliver group mode switching, temperature adjustment, on/off control, etc., with rich functions, flexible and convenient application.

Intelligent Combination Control Function

Terminal interlock control

: Chiller will automatically start/stop in accordance with the terminal unit(AHU, FCU) status.

Chilled water pump interlock control

: Chiller will automatically start/stop the water pump when it is not working synchronously with the terminal unit, to avoid any damage to the whole system.

Fault alarm:

The control system can connect to the audio and video alarm system or other prompts, to inform user for any failure

Remote switch control

: Unit start/stop can be realized by the remote switch.

System auxiliary heat source interlock control

: The starting conditions of the auxiliary heat source are determined by the multi-variable system. The start/stop of the auxiliary heat source are controlled intelligently.

Running status

: The system can output unit operation status feedback signal to user side for easy checking at any time

Free Access to Building Management System

Standard RS485 building communication interface comes with open source ModBus standard communication protocol. The device can be easily connected to the building management system(BMS) for centralized control, easy to achieve intelligent control, avoid unnecessary energy waste, and save air-conditioning operating costs.

Specification

|

Model/Specification

|

|

HFW-65HA1

|

HFW-65HA1-L

|

HFW-130HA1

|

HFW-130HA1-L

|

||||

|

|

|

Normal temperature type

|

Low-temperature type

|

Normal temperature type

|

Low-temperature type

|

||||

|

Nominal cooling capacity(KW)

|

|

65

|

63

|

130

|

130

|

||||

|

Nominal heating capacity(KW)

|

|

71

|

71

|

142

|

141

|

||||

|

Cooling

|

Rated total input power(KW)

|

19.5

|

18.7

|

39

|

37.7

|

||||

|

Heating

|

Rated total input power(KW)

|

21

|

19.5

|

42

|

38.8

|

||||

|

Nominal low-temperature cooling capacity(KW)

|

|

/

|

52

|

/

|

100

|

||||

|

Total nominal low-temperature heating input power(KW)

|

|

/

|

18.6

|

/

|

37

|

||||

|

Voltage

|

|

380V/3N~/50Hz

|

|

|

|

||||

|

Refrigerant

|

|

R410A

|

|

|

|

||||

|

Throttle parts

|

|

Electronic expansion valve

|

|

|

|

||||

|

Compressor

|

Type

|

Hermetic scroll

|

|

|

|

||||

|

|

Qty

|

2

|

|

|

|

||||

|

Fan

|

Type

|

Axial low noise fan

|

|

|

|

||||

|

|

Power(kw)

|

0.9*2

|

|

1.5*2

|

|

||||

|

Airside heat exchanger

|

Airflow(m³/h)

|

14000*2

|

|

19500*2

|

|

||||

|

|

Type

|

High-efficient finned heat exchange

|

|

|

|

||||

|

Waterside heat exchanger

|

Nominal water flow(m³/h)

|

11.5

|

11.5

|

22.5

|

22.5

|

||||

|

|

Type

|

High-efficient shell&tube heat exchanger

|

|

|

|

||||

|

Water pressure drop(kPa)

|

|

30

|

|

40

|

|

||||

|

Water inlet/outlet connection pipe

|

|

DN50

|

|

DN65

|

|

||||

|

Dimension(W*H*D)

|

|

1810*960*2350

|

|

2011*1100*2300

|

|

||||

|

Net weight(kg)

|

|

580

|

600

|

1000

|

1050

|

||||

Application

Hot Searches