- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Building

-

Design Style:

-

Modern

-

Type:

-

steel prop

-

Place of Origin:

-

Hebei, China, Hebei China

-

Brand Name:

-

SANYE

-

Model Number:

-

Steel prop

-

Material:

-

Q195 / Q235

-

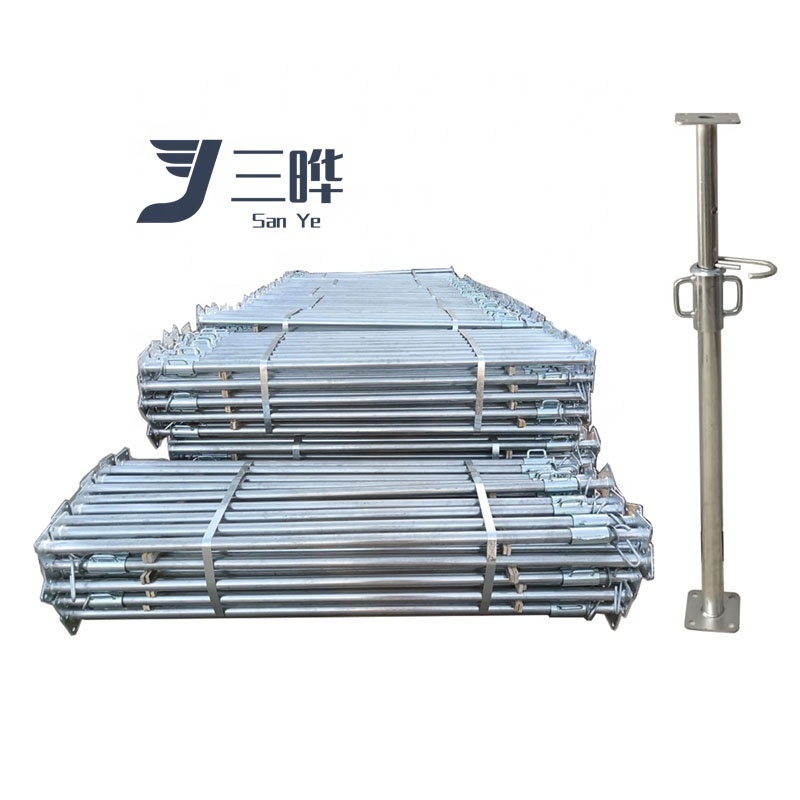

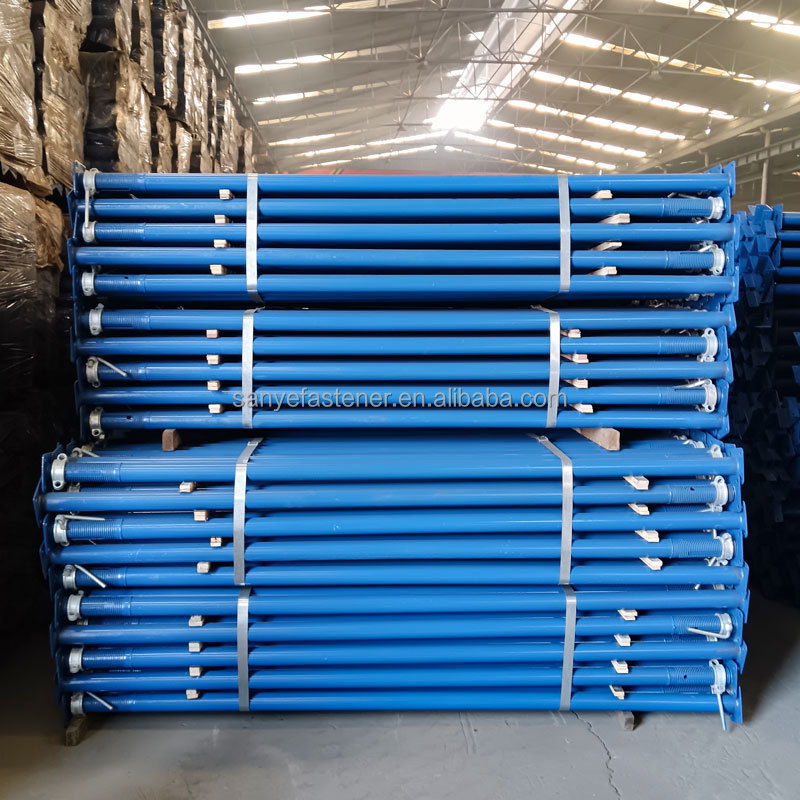

Color:

-

Customer Requirements

-

Packing:

-

Bundle

-

Advantage:

-

Stable

-

Surface treatment:

-

Galvanized/Painted

-

Certificate:

-

ISO900/ISO14001/OHSAS 18001

Quick Details

-

Warranty:

-

NONE

-

After-sale Service:

-

NONE

-

Project Solution Capability:

-

NONE

-

Application:

-

Building

-

Design Style:

-

Modern

-

Type:

-

steel prop

-

Place of Origin:

-

Hebei, China, Hebei China

-

Brand Name:

-

SANYE

-

Model Number:

-

Steel prop

-

Material:

-

Q195 / Q235

-

Color:

-

Customer Requirements

-

Packing:

-

Bundle

-

Advantage:

-

Stable

-

Surface treatment:

-

Galvanized/Painted

-

Certificate:

-

ISO900/ISO14001/OHSAS 18001

SANYE galvanize adjustable scaffold framework concrete customizable for steel prop jack

Product Description

Our Services

1.

Free Samples

2.

The Delivery Time Is 15 Days, And The Customized Products Are 25 Days

3, Support Customized Product Packaging

4, Support Product ODM,OEM

5, Support Online Installation Technical Guidance

6. 24 Hours Online Response To Customers

7. One-Stop Service

|

Middle East Type Prop

|

|

|

|

|

||||

|

Adjustable Height

(mm) |

Inner Tube OD

(mm) |

Outer Tube OD

(mm) |

Thickness

(mm) |

Surface Treatment

|

||||

|

1800-3200

|

48

|

60

|

2/3.0/3.5

|

Powder Coated/

Electric galvanized/Painted/Hot dip galvanizing |

||||

|

2000-3500

|

48

|

60

|

2/3.0/3.5

|

|

||||

|

2200-4000

|

48

|

60

|

2/3.0/3.5

|

|

||||

|

2800-5000

|

48

|

60

|

2/3.0/3.5

|

|

||||

|

Italian Type Prop

|

|

|

|

|

||||

|

Adjustable Height

(mm) |

Inner Tube OD

(mm) |

Outer Tube OD

(mm) |

Thickness

(mm) |

Surface Treatment

|

||||

|

1600-2900

|

48

|

56

|

2/3.0/3.5

|

Powder Coated/

Electric galvanized/Painted/Hot dip galvanizing |

||||

|

1800-3200

|

48

|

56

|

2/3.0/3.5

|

|

||||

|

2000-3600

|

48

|

56

|

2/3.0/3.5

|

|

||||

|

2200-4000

|

48

|

56

|

2/3.0/3.5

|

|

||||

|

Spanish Type Prop

|

|

|

|

|

||||

|

Adjustable Height

(mm) |

Inner Tube OD

(mm) |

Outer Tube OD

(mm) |

Thickness

(mm) |

Surface Treatment

|

||||

|

1600-2900

|

40

|

48

|

2/3.0/3.5

|

Powder Coated/

Electric galvanized/Painted/Hot dip galvanizing |

||||

|

1800-3200

|

40

|

48

|

2/3.0/3.5

|

|

||||

|

2000-3500

|

40

|

48

|

2/3.0/3.5

|

|

||||

|

2200-4000

|

40

|

48

|

2/3.0/3.5

|

|

||||

Product Size

Inner tube diameter:40mm

Outer tube diameter48mm

Height:200mm

Base plate size:120mm

Base plate thickness:120mm

Cup nut diameter:60mm

Manufacture Process

Step 1,

CUTTING —

Steel pipes (both external and internal) are then cut to size with a +/-1 mm tolerance. Cutting is done using automatic cutting machines: a bundle of pipes is placed on the loader which selects one pipe at a time. It is then loaded on a positioning device and cut precisely at the desired height. Lastly, the pipe is unloaded into a container for the subsequent step.

Step 2,

DRILLING —

Then there follows the drilling step, which is carried out depending on the type of pipe. Due to the new technologies, the drilling is quick, precise and burr-free.

Step 3,

WELDING

—

External pipes proceed to the welding step, where - suitably positioned - they are assembled with the base plate and the end is threaded . Once drilled, the internal pipes undergo the same welding process but concerning the plate only.

Step 4,

COATING AND GALVANISING —

Once welded, the props can be: dip coated, cold-dip galvanised (electrolytically), for a more durable protection with respect to dip coating and for better aesthetic quality, or hot dip galvanised for a basically permanent protection, suitable for all environments and withstanding external atmospheric agents.

Step 5,

FINISH —

Depending on the product, next come the completion steps including: mounting an outer sleeve on the covered threading or a forged steel ring nut.

Step 6,

CUSTOMISATION —

Customised products are available upon request: for example with a ring nut bearing the customer’s colours, or the customisation of the prop using stickers bearing the customer’s logo.

Step 7,

PACKAGING AND SHIPMENT —

Once concluded with machining, we proceed to the packaging step. Packages usually come with 40 pieces, strapped. The material is then loaded into a truck or container and shipped.

Recommend Products

Packing & Delivery

Ton bag, wooden pallet,wooden case,iron pallet;

Customized according to customer requirements.

Hot Searches