- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Feininger

-

Model Number:

-

X350

-

Marketing Name:

-

XPS Blue Board

-

Color:

-

Blue

-

Width:

-

600mm / 900mm / 1200mm

-

Length:

-

1200mm-3000mm(or any)

-

Thickness:

-

10, 20, 25, 50, 75, 100, 150 mm

-

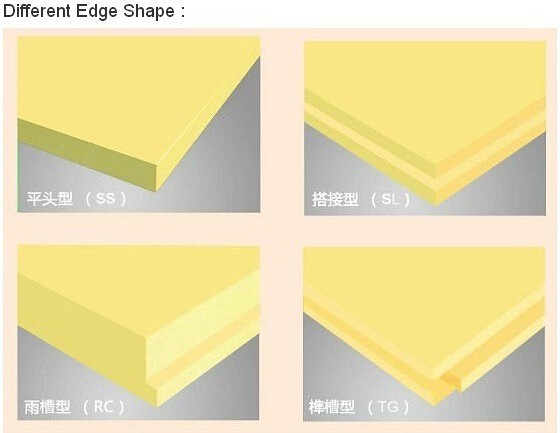

Edge Shape:

-

SL SS T&G

-

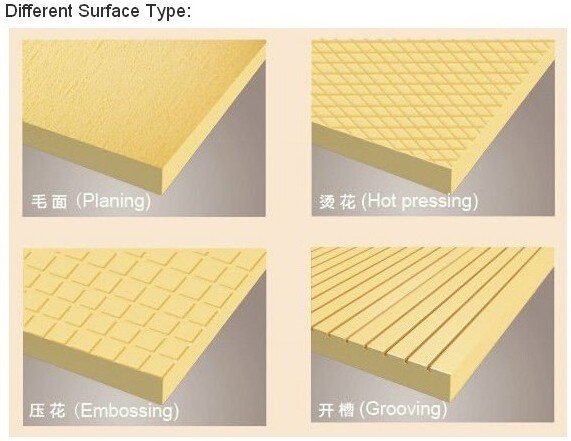

Surface:

-

Withskin / Roughing / Embossing

Quick Details

-

Warranty:

-

5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection

-

Project Solution Capability:

-

Others

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Feininger

-

Model Number:

-

X350

-

Marketing Name:

-

XPS Blue Board

-

Color:

-

Blue

-

Width:

-

600mm / 900mm / 1200mm

-

Length:

-

1200mm-3000mm(or any)

-

Thickness:

-

10, 20, 25, 50, 75, 100, 150 mm

-

Edge Shape:

-

SL SS T&G

-

Surface:

-

Withskin / Roughing / Embossing

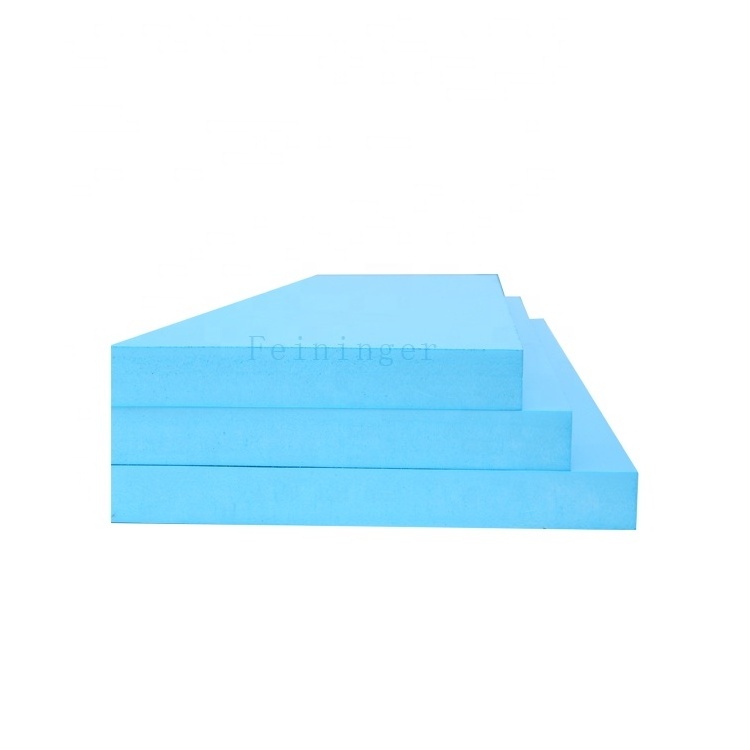

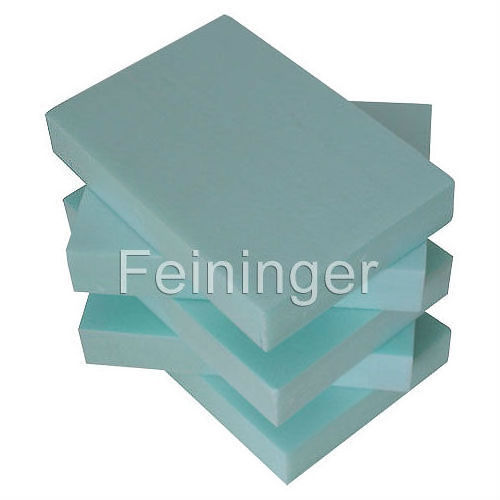

XPS Blue insulation Board, plastic sheet

XPS Blue Board

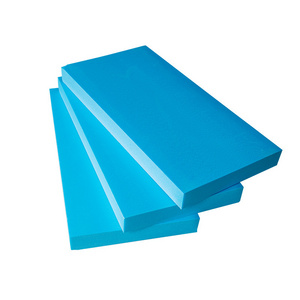

1.Thickness: 10-120mm

2.Width: 600-1200mm

3.Density: 30-50Kg/m3

XPS foam board is an extruded polystyrene insulation manufactured through a plastic extrusion process.

XPS Insulation Board Production Process : Polystyrene Granule, Talcum Powder, Masterbatch, Blowing Agent are mixed and melted in Extruder.The melt material will be extruded out of Slot Die, then through Calibrator, we reach a panel shape. After cooling, cutting, edge trimming, we will pack in water-proof plastic bag. This is the XPS Foam Board in market.

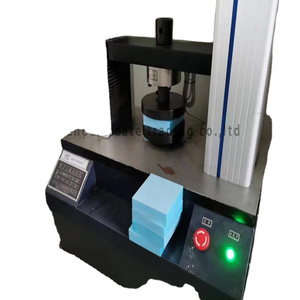

- Stable performance and anti-aging : The extruded polystyrene (XPS) insulation boards can be used 35-50 years.

- Resistance to compression : compared with other thermal insulation material(200Kpa for EPS), it has better compressive strength(around 300Kpa), which make it the ideal solution for heavy domestic or industrial loads

- Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture

- Lightweight : volume optimization and easy to handle

- Resistance to deformation

- Resistance to impact

-

Versatile

:

the closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape

100% ozone friendly - Recyclable : Polyfoam can be 100% recycled

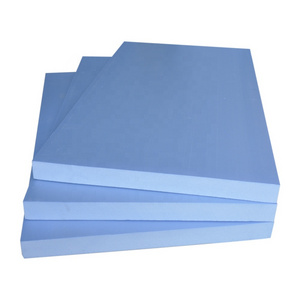

XPS Blue Board

Plastic Bag Packing

68.4M3/40HQ

Container Loading

|

Size Length (mm) |

Pcs/Pack |

M 2 /Pack |

|

2400*600*25 |

18 |

25.92 |

|

2400*600*50 |

9 |

12.96 |

|

2400*600*75 |

6 |

8.64 |

|

2400*600*100 |

4 |

5.76 |

Manufacture brand-new XPS Blue Board

Carry out on-line quality supervision and test the insulation material before shipping

Pack XPS Foam in plastic bag

Issue Test Report

Ship the material by full container load

Make arrangement of transportation

Instruct how the XPS foam board is applied.