- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

100X

-

Brand Name:

-

THT

-

Pressure:

-

0.6Mpa

-

size:

-

DN20-450

-

Body material:

-

cast iron, carbon steel, stainless steel

-

O Type Seal Ring Material:

-

NBR/EPDM

-

Medium:

-

Water

-

Stem:

-

2Cr13

-

Diaphragm:

-

NBR/EPDM

-

Gasket:

-

cast iron, carbon steel, stainless steel

-

Spring:

-

Stainless steel

-

seat:

-

Stainless steel/Copper alloy

Quick Details

-

Port Size:

-

DN20-DN450

-

Warranty:

-

12 months

-

Place of Origin:

-

Tianjin, China

-

Model Number:

-

100X

-

Brand Name:

-

THT

-

Pressure:

-

0.6Mpa

-

size:

-

DN20-450

-

Body material:

-

cast iron, carbon steel, stainless steel

-

O Type Seal Ring Material:

-

NBR/EPDM

-

Medium:

-

Water

-

Stem:

-

2Cr13

-

Diaphragm:

-

NBR/EPDM

-

Gasket:

-

cast iron, carbon steel, stainless steel

-

Spring:

-

Stainless steel

-

seat:

-

Stainless steel/Copper alloy

Product Description

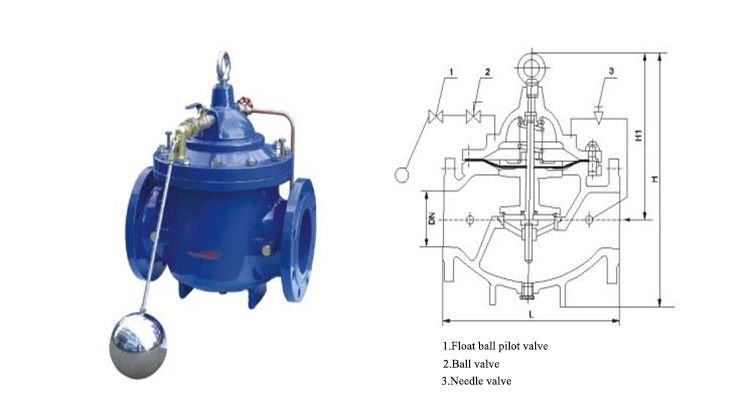

Automatic remote water level controller floating ball valve

Brief introduction:

Remote controlled floating ball water level controller are installed in the inlet of pool or water tower to control the height of water level. The main body is controlled the open & close for water by float ball. When water level declined, the body will open by float ball pilot to supply water to pool or tower automatically. When the water level reached the given place, the main body will close by float ball pilot to stop the pouring.

Remote controlled floating ball water level controller are installed in the inlet of pool or water tower to control the height of water level. The main body is controlled the open & close for water by float ball. When water level declined, the body will open by float ball pilot to supply water to pool or tower automatically. When the water level reached the given place, the main body will close by float ball pilot to stop the pouring.

Details Images

|

|

|

|

|

|

||||

|

No

|

PDiaphragm valve

|

|

Piston valve

|

|

||||

|

|

Part name

|

Material

|

Part name

|

Material

|

||||

|

1

|

valve cover

|

cast iron, carbon steel, stainless steel

|

Valve cover

|

cast iron, carbon steel, stainless steel

|

||||

|

2

|

Spring

|

stainless steel

|

Cylinder liner

|

stainless steel

|

||||

|

3

|

Diaphragm pressboard

|

Pcast iron, carbon steel, stainless steel

|

Piston

|

Ductile iron

|

||||

|

4

|

Diaphragm

|

NBR,EPDM

|

Sealing ring

|

NBR,EPDM

|

||||

|

5

|

Stem

|

2Cr13

|

Stem

|

2Cr13

|

||||

|

6

|

valve cover

|

cast iron, carbon steel, stainless steel

|

Spring

|

stainless steel

|

||||

|

7

|

O type sealing ring

|

NBR EPDM

|

Valve disc

|

Ductile iron

|

||||

|

8

|

O type sealing ring pressboard

|

cast iron, carbon steel, stainless steel

|

Gasket

|

NBR,EPDM

|

||||

|

9

|

Valve seat

|

copper alloy, stainless steel

|

Valve seat

|

copper alloy, stainless steel

|

||||

|

10

|

Valve body

|

cast iron, carbon steel, stainless steel

|

Sealing pressboard

|

Ductile iron

|

||||

|

11

|

|

|

valve body

|

cast iron, carbon steel, stainless steel

|

||||

|

Applications Standards

|

|

|

||

|

Quality Assurance: ISO9000

|

Face To Face: Q/BYL-2002

|

Test Standard: GB/T13927 API1598

|

||

|

Design: Q/yyf-2000

|

Flange: GB/T17241.6 GB/T9113

|

|

||

|

Technical Data

|

|

|

|

|||

|

Pressure(Mpa)

|

1.0

|

1.6

|

2.5

|

|||

|

Shell test pressure(Mpa)

|

1.5

|

2.4

|

3.75

|

|||

|

seal test pressure(Mpa)

|

1.1

|

1.76

|

2.75

|

|||

|

Gas seal test pressure(Mpa)

|

0.6

|

0.6

|

0.6

|

|||

|

Suitable Temperature

|

≦80℃

|

≦80℃

|

|

|||

|

Suitable Medium

|

Water

|

|

|

|||

Features:

1. Work stable and reliable and big flow pass.

2. Disc open quickly and close slowly without water hammer.

3. High precision reducing regulator with large range.

4. Sealing performance and long service life.

Installation Requirements:

1. Recommend to install exhuast valve in pipe system to make sure the steady working.

2. Pressure of inlet should not less than 0.2Mpa. If it does, the performance will be worse. (Pressure tolerance of outlet will

increase.)

1. Work stable and reliable and big flow pass.

2. Disc open quickly and close slowly without water hammer.

3. High precision reducing regulator with large range.

4. Sealing performance and long service life.

Installation Requirements:

1. Recommend to install exhuast valve in pipe system to make sure the steady working.

2. Pressure of inlet should not less than 0.2Mpa. If it does, the performance will be worse. (Pressure tolerance of outlet will

increase.)

Recommend Products

Hot Searches