- Product Details

- {{item.text}}

Quick Details

-

Max. Wheel Weight:

-

no limitation

-

Place of Origin:

-

China

-

Brand Name:

-

All4car

-

Model Number:

-

G781

-

Warranty:

-

1 Years

-

Certificate:

-

CE

-

Software:

-

multi-language

-

Free:

-

Update software and fittings

-

Feature:

-

Android table PC ,2 LCD screen

-

Function:

-

auto lifting to Wheel Angel Test

-

configuration:

-

Brand Acer/ Lenove and Canon

-

Software Datebase:

-

AUTODATA 25,000 original car datebases

-

Camera:

-

5000,000 Piexl Imported Cameras

-

Measurement:

-

Toe/Camber/ Caster/S.A.I (or KPI)/Thrust Angle

-

Weight:

-

296kg

Quick Details

-

Power:

-

50HZ/60HZ

-

Power Supply:

-

220V

-

Balancing Speed:

-

no limitation

-

Max. Wheel Weight:

-

no limitation

-

Place of Origin:

-

China

-

Brand Name:

-

All4car

-

Model Number:

-

G781

-

Warranty:

-

1 Years

-

Certificate:

-

CE

-

Software:

-

multi-language

-

Free:

-

Update software and fittings

-

Feature:

-

Android table PC ,2 LCD screen

-

Function:

-

auto lifting to Wheel Angel Test

-

configuration:

-

Brand Acer/ Lenove and Canon

-

Software Datebase:

-

AUTODATA 25,000 original car datebases

-

Camera:

-

5000,000 Piexl Imported Cameras

-

Measurement:

-

Toe/Camber/ Caster/S.A.I (or KPI)/Thrust Angle

-

Weight:

-

296kg

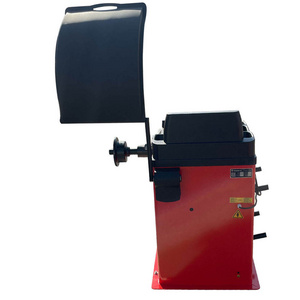

Professional3D wheel alignment and balancing machine used for garage equipment

Quick Details

| Technology parameter | ||||

| Items | Front wheel measurement precision | Front wheel measurement range | Rear wheel measurement precision | Rear wheel measurement range |

| Toe | ±0.02 | ±20° | ±0.02 | X |

| Camber | ±0.02 | ±15° | ±0.02 | ±20° |

| S.a.i | ±0.02 | ±26° | X | ±15° |

| Caster | ±0.02 | ±26° | X | X |

| Thrust angle | X | X | ±0.02 | ±5° |

The software Operation Process of 2 Post Wheel Alignment

Select model data - Cart measurement - Data review - Install brake retainer - Lift vehicle - Kingpin measurement Install the steering wheel retainer - four wheel positioning adjustment - check steering wheel level

Options:

Application software could be installed in the table PC with Android system. Clients can long-distance operate the wheel alignment measurement through Bluetooth.

Product Details:

1. software interface display

The main positioning parameters of front and rear wheels are displayed on the same screen.

2. Global vehicle database - Genuine database

3. Cloud service function

Remote technical support one key upgrade

4. Multiple software skin styles to select

Data preview

Front, rear wheel's measurement result can be displayed in one interface

Two dimensional dynamic display

Can switch to different interface according to cutomers' requirements.

5. Multi-languages

6. Global car's database

The most authoritative autodata legitimate database.

7. Multiple print modes

Humanization print report can help customers got different options for different requiry.

8. Part name - Wheel alignment damps

Accessonies material - alumihum a boy muterial

accessonies - fxed relector

applicable models - sedan commercial vehical, minbus, etc

9. Part name - camena assembly

Accessonies material - special materal

Accessones - take photon

Aplicable models - sedan commercial vehical, minbus, etc

10. Part name - 32-inch display

Accessonies material - international big brand

Accessones - display data

Aplicable models - sedan commercial vehicle, minbus, etc

11. Part name - target

Accessonies material - speclal material

Accessones - coordinate with measurement data

Aplicable models - sedan commercial vehicle, minbus, etc

12. 3D measurement technology

which based on car body, more precision and stable. Camera measurement system using two camera and work together with four target disks, which is a revolutionary measurement method. Target disk - there isn’t electronic components inner and efficiently to eliminate the equipment error which caused by circut. Calibration - only need once RCP calibration after installation, process simple and repeated calibration is unnecessary. Software system, simple operation, measurement can be finished in 2 minutes.

Advantage:

Wireless, no electronic sensor and components, can avoid some questions caused by sensor error. Measurement precision is not affected by the unbalance of vehicle and car lift. Wheel an rim compensatio is unneccessay for measurement process. The advantage incrase the accuracy and reliability of measurement, improve the working efficiency.

A ccording to weight of camera beam, the lifing pillar equipped with two pieces of metal counter weight, which can efficiently lower the motor working pressure, thus prolonging the working life.

Using a one-piece lifting column designed with ball screw and linear guide, the low-spee dc motor is equipped to ensure the automatic tracking and lifting of the camera beam without shaking.

Improve work efficiency and ensure equipment reliablity.