- Product Details

- {{item.text}}

Quick Details

-

Production Way::

-

Extrusion

-

Hardness::

-

30-50 shore A

-

Color::

-

Black, Grey, White, red, yellow, or customized

-

Applications:

-

Car, Door, Window, Container, Machinery, Boat, and etc

-

Function::

-

Waterproof, windproof, anti-dust, ozone resistance, etc

-

Packing::

-

Plastic bag + carton or customized

-

Certificate::

-

ISO9001,TS16949,etc

Quick Details

-

Place of Origin:

-

Hebei, China

-

Standard or Nonstandard:

-

Nonstandard

-

Material::

-

EPDM/PVC

-

Production Way::

-

Extrusion

-

Hardness::

-

30-50 shore A

-

Color::

-

Black, Grey, White, red, yellow, or customized

-

Applications:

-

Car, Door, Window, Container, Machinery, Boat, and etc

-

Function::

-

Waterproof, windproof, anti-dust, ozone resistance, etc

-

Packing::

-

Plastic bag + carton or customized

-

Certificate::

-

ISO9001,TS16949,etc

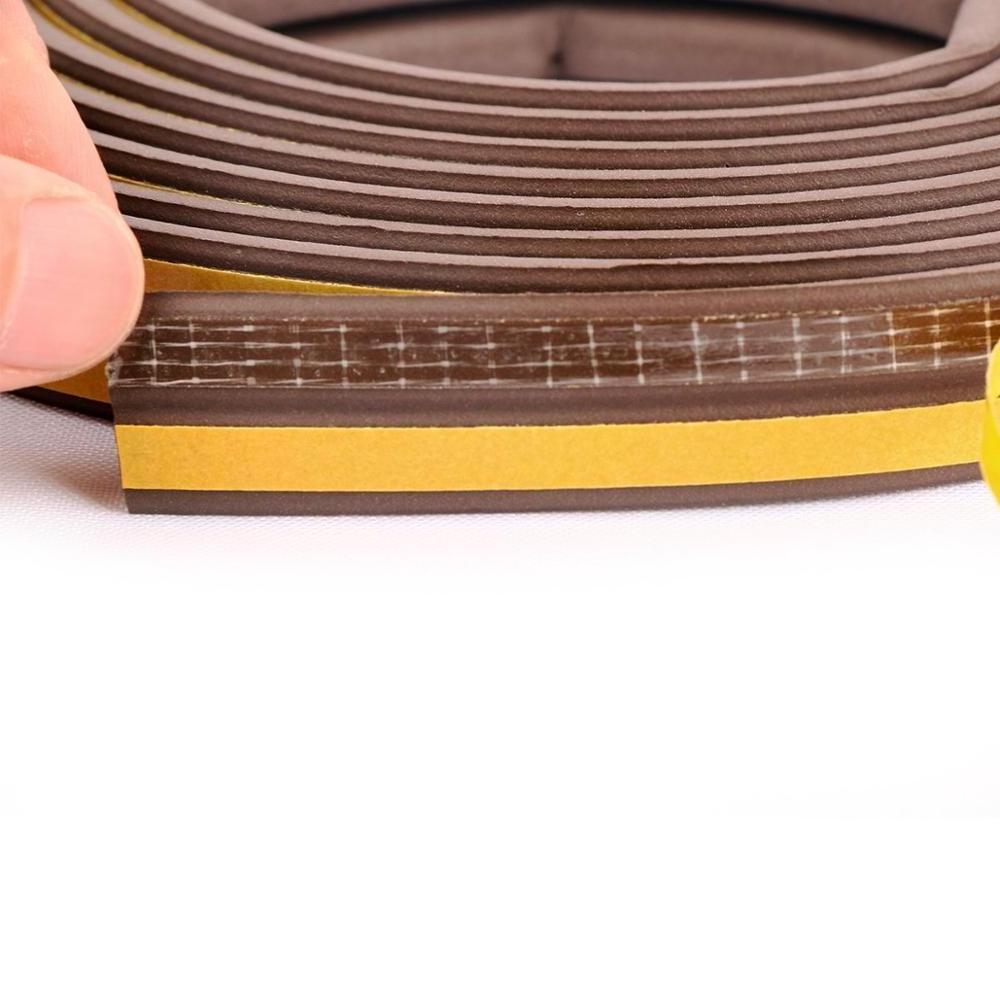

Brown color weather Stripping D-shape Sponge Rubber Door Seal Strip double sided adhesive EPDM foam Tape

Main products include all kinds of rubber & plastic extrusions and molding press widely used for

door and window steal strip,car door seals, gaskets, boat fender , tubes, pipes, rubber hose, etc.

Most of the time, clients require us to do custom service, because seal strips are usually different in size and profiles due to different application and designs, it's convenient for us to make a new mould and produce the unique products only for you!

Please never hesitate to contact with us if you have a drawing, picture, sample or even an idea

Below chart shows the possibility for what we can do

|

Materials |

NBR,EPDM,neoprene,butyl rubber,Viton/FKM,silicone, PVC, PC, PU, PE, etc |

| Color | Any color by pointed |

| Shape | According to clients' drawing or sample |

| Craft | extrusion, co extrusion, tri extrusion, Compression, injection |

| Hardness | 20~90 shore A, we can do both foam and solid rubber |

| Certificates | ISO/ TS16949 |

| Package | Inner plastic bag, outside carton and pallet |

| Payment Terms | L/C,T/T,Western Union, paypal, etc |

| Port | Tianjin/Qingdao |

| Delivery Time |

extrusion moulds need 3-7 days, compress moulds need 15-20 days, injection moulds need about 25 days extrusion production needs about 7- 10 days, moulding production needs about 20-30 days |

Products Pictures :