- Product Details

- {{item.text}}

Quick Details

-

Power:

-

24kw

-

Dimension(L*W*H):

-

45000*1250*1400

-

Weight:

-

6000 KG

-

Output product name:

-

Wafer biscuits

-

Name:

-

waffle production line

-

Material:

-

304 Stainess Steel waffle production line

-

Type:

-

Full automatic waffle production line

-

Capacity:

-

100-1000kg/h

-

Function:

-

Multifunctional

-

Biscuit Type:

-

Soft Hard Soda Sandwich Biscuit

-

Power Source:

-

Electric Power

-

MOQ:

-

1 Set

-

Application:

-

Biscuit Cookie Cracker Processing

Quick Details

-

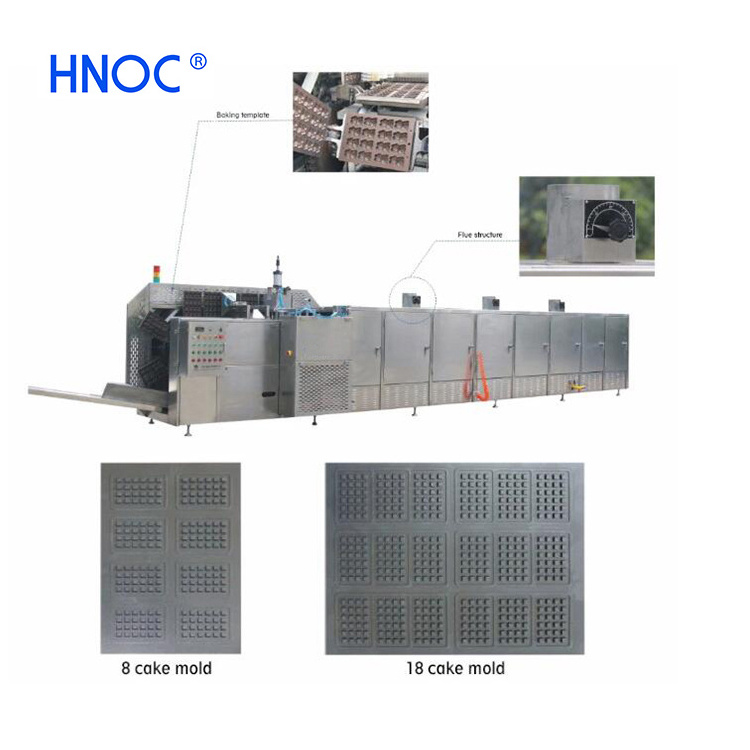

Brand Name:

-

HNOC

-

Place of Origin:

-

Henan China

-

Voltage:

-

380V

-

Power:

-

24kw

-

Dimension(L*W*H):

-

45000*1250*1400

-

Weight:

-

6000 KG

-

Output product name:

-

Wafer biscuits

-

Name:

-

waffle production line

-

Material:

-

304 Stainess Steel waffle production line

-

Type:

-

Full automatic waffle production line

-

Capacity:

-

100-1000kg/h

-

Function:

-

Multifunctional

-

Biscuit Type:

-

Soft Hard Soda Sandwich Biscuit

-

Power Source:

-

Electric Power

-

MOQ:

-

1 Set

-

Application:

-

Biscuit Cookie Cracker Processing

Chinese manufacturer automatic soft waffle maker machine waffle production line

| Raw material | Cookie Material |

| Name | soft waffles machine |

| Material | 304 Stainess Steel |

| Capacity | 100-1000kg/h |

| Type | Fully Automatic |

| Condition | New |

| Function | Multifunctional |

| Biscuit Type | Soft Hard Soda Sandwich Biscuit |

| Condition | NEW Wafer Biscuit Machine Production Line |

| MOQ | 1 SET |

1. Full automatic PLC controlled,highly stable and reliable . Servo system not only minimize the maintenance cost and contamination to products, but also realize a more stable and bigger center filling.

2.The Beckhoff Remote Control System from Germany enables us to modify system parameters,diagnosis & troubleshooting on line, which is not only easy and fast, but also cost-saving.

3.There are a lot of add-on devices can be attached to this production line , such as Auto Biscuits Feeder, Auto Wafer Feeder, Auto Sprinkler,etc. Customers can choose these add-on devices accordingly and add or change the add-on devices for new product whenever needed.

4.The high configuration production line can be combined by all kind of parts, and these parts can be separated and recombined with some other parts to makes another production line for different products.

5.There are single depositor,double depositor or more to meet different product production need. The special mechanism of the depositor device makes the installation, takedown and switch of the depositor EASY & FAST. It only takes a very short time to clean the depositor or switch to another depositor.

6.To produce different kinds of chocolate products , you only need to change a depositor or the chocolate

syrup distribution plate that used with the depositor.

7.The mobile depositor enables the mobile mould- follow-depositing function , which greatly increase the output of the production line by 20%.

8.With plastic guide-rail protection , the chain will not contact with spilled chocolate,which meets the overall food hygiene requirements.

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.