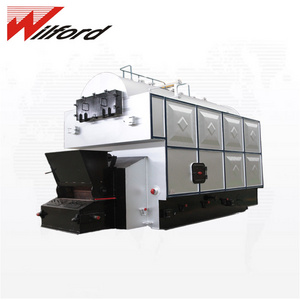

The scale chain grate boiler could resist the temperature as high as 1200℃, long working life. It has a low coal leakage because of the small gap. High automatic degree, decrease labor cost. Convenient for maintenance, it could be done without boiler shut down.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

3~50ton

-

Design fuel:

-

Coal Fired or biomass fired

-

Color:

-

Customer's Requirement

-

Material:

-

Thicker Stainless Steel

-

Thermal efficiency:

-

90%

-

Evaporation:

-

1~6ton/h

-

Keywords:

-

Chain Grate steam boiler

-

Package:

-

Nude

-

Steam temperature:

-

170℃,184℃,193℃,204℃

-

Application:

-

Industrial Production

-

OEM:

-

Support

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xinda

-

Dimension(L*W*H):

-

Depends

-

Weight:

-

3~50ton

-

Design fuel:

-

Coal Fired or biomass fired

-

Color:

-

Customer's Requirement

-

Material:

-

Thicker Stainless Steel

-

Thermal efficiency:

-

90%

-

Evaporation:

-

1~6ton/h

-

Keywords:

-

Chain Grate steam boiler

-

Package:

-

Nude

-

Steam temperature:

-

170℃,184℃,193℃,204℃

-

Application:

-

Industrial Production

-

OEM:

-

Support

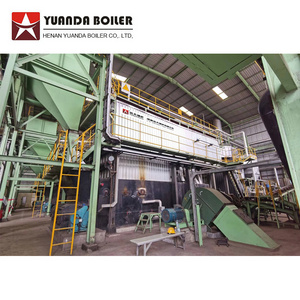

Furnace chain fire grate stoker coal fired steam boiler central heating boiler

|

Item

|

Unit

|

Data

|

Item

|

Unit

|

Data

|

|

Rated evaporation

|

t/h

|

1

|

Design Efficiency

|

%

|

92

|

|

Rated working pressure

|

Mpa

|

0.7/1.0

|

Steam Temperature

|

℃

|

184

|

|

Combustion consumption

|

Kg/h

|

111

|

Size

|

m

|

5.2*2.1*3.6

|

1.Suitable for burning biomass fuels, pure coal or mixed coal.

2.The economizer in the boiler tail. Remove ash, slag can be directly used as fertilizer, which is a highly efficient energy saving and environmental protection.

3.Boiler equipped with drum and spiral slag machine mechanical slag to control the boiler. The monitoring instrument is complete and boiler can be safe and reliable operation.

Furnace chain fire grate stoker coal fired steam boiler central heating boiler Technical characteristics

1.In the lower part of the pot, the bottom of the boiler tube is removed, and the stagnant water area at the bottom of the drum is eliminated, so that the sludge is not easy to deposit, and the high temperature area of the drum can be well cooled, preventing the bottom drum of the pan.

2.The heat transfer effect is obtained by using the high efficiency heat transfer screw pipe, and the heating efficiency of the boiler is improved.

3.The structure is compact, and compared with the same type boiler, the external dimension is small, and the investment of boiler room infrastructure is saved.

4.Stable, stable operation, convenient adjustment and sufficient output.With 110% overload capacity.

5.The heat transfer coefficient and thermal efficiency have been improved by using the smoke tube.The smoke pipe is not easy to accumulate ash, play the role of self-cleaning.

|

Model

|

Rated evaporation

(t/h)

|

Rated working

pressure (Mpa)

|

Steam temperature

(℃)

|

Boiler efficiency

(%)

|

|

DZL1-0.7/1.0

|

1

|

0.7/1.0

|

170/184

|

>90

|

|

DZL2-1.25/1.6

|

2

|

1.25/1.6

|

193/204

|

>90

|

|

DZL4-1.25/1.6

|

4

|

1.25/1.6

|

193/204

|

>90

|

|

DZL6-1.25/1.6

|

6

|

1.25/1.6

|

193/204

|

>92

|

|

DZL10-1.25/1.6

|

10

|

1.25/1.6

|

193/204

|

>92

|

|

DZL15-1.25/1.6

|

15

|

1.25/1.6

|

193/204

|

>94

|

|

DZL20-1.25/1.6

|

20

|

1.25/1.6

|

193/204

|

>94

|

If the above table does not have the parameters you want, please contact us and we will provide the information and parameters you need.

All the parts of Boiler Manufacturer for Myanmar are high quality and meet the coal fired boiler production standards.

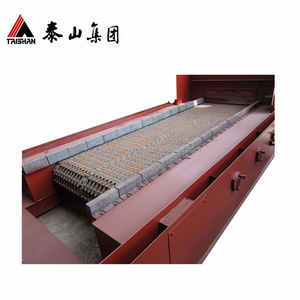

Chain Grate Stoker

Economizer

Economizer is the boiler tail flue in the boiler feed water heated to the steam pressure under the saturated water heating surface, because it absorbs relatively low temperature flue gas, reducing the smoke exhaust gas temperature, saving energy, improve the efficiency.

Dust Collector

Multi-cyclone dust, corrosion-resistant, wear-resistant, high temperature, the service life of up to 20 years, the Department of the domestic initiative, the precipitator operating performance is stable and reliable, easy management, simple maintenance, no operating costs, small footprint ,Wide range of applications

Blower

Blowers are volumetric blowers. When used, with the pressure changes, the flow of change is very small. But the flow changes with the speed. Safe operation, long service life is a major feature of blower products.

Delivery

According to buyer's requirements or on the basis of the seller location to choice land transportation or shipping.

Cart transport to Qingdao port, Tianjin Port and Shanghai port.

Packing

The host is nude packing, auxiliary machinery and vulnerable part to the wooden box. According to the size of boiler determine whether need open top cabinet.

For 1-4ton boilers, use 20-40'FT container packing for marine shipment.

For boilers above 5ton,use 40'FT flat rack packing for marine shipment.

Depending on your needs, we can let the engineers guide the installation or we can get our professional team to install it for you personally.

Our factory has a special equipment production license. The Furnace chain fire grate stoker coal fired steam boiler central heating boiler Design meets the international standards for certification and recognized by the international community.

How to get a boiler price list?

Please tell us below to confirm a boiler model and offer the right boiler price:

1) what is the application ?

2) what is the capacity do you need?

3) what is the pressure you need.

4) which fuel do you want to use for the boiler, coal, biomass, gas & oil, or others?

How long is the product warranty period?

Our product have at least 12 months warranty period.

How about the installation?

Guide installation online or staff installation by our staffs, but you have to afford the extra cost if If we send professional staff overseas to install it.

If you have any questions or Suggestions, please feel free to contact us. We will try our best to help you.