- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2660*1640*3865mm

-

Motor Power (kW):

-

2.2

-

Weight (T):

-

23.2

-

Warranty of core components:

-

24 months

-

Stroke of sliding block:

-

250mm

-

Product name:

-

Power Press machine

-

Keyword:

-

Power press

-

Function:

-

Punching Ang Press

-

Material:

-

Hard Steel

-

Color:

-

Customizable

-

Name:

-

Metal Stamping Press

-

Application:

-

Metal Sheet Stamping

-

Type:

-

JH21-250

-

Usage:

-

Metal Press

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

rbqlty

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

2660*1640*3865mm

-

Motor Power (kW):

-

2.2

-

Weight (T):

-

23.2

-

Warranty of core components:

-

24 months

-

Stroke of sliding block:

-

250mm

-

Product name:

-

Power Press machine

-

Keyword:

-

Power press

-

Function:

-

Punching Ang Press

-

Material:

-

Hard Steel

-

Color:

-

Customizable

-

Name:

-

Metal Stamping Press

-

Application:

-

Metal Sheet Stamping

-

Type:

-

JH21-250

-

Usage:

-

Metal Press

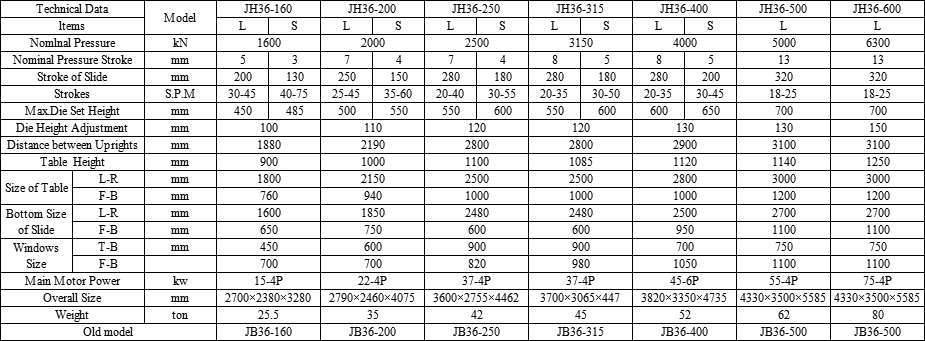

200 ton H frame double crank pneumatic press with dry clutch

JH36 series Double Crank Pneumatic Press is equipped with a wet clutch and a stronger H frame body. The symmetrical front-rear column structure design minimizes deflection and is most suitable for precision progressive die applications. No inherent angular deflection, which significantly extends die life and reduces cost of tooling maintenance. High rigidity structure ensures consistent dynamic precision. High torque, enclosed wet clutch brake unit requires minimal maintenance, eliminates noise and pollution caused by airborne particles, and significantly extends lining life. The press is designed to allow simple integration with automated auxiliary equipment.

Features

1.Steel welded body with high rigidity

The main body is welded with high quality steel plate. Then it will be heat treated and ball blasting treated to release the stress and improve the rigidity. The best boring and milling machine ensures the high precision of the body.

2.High torque low noise wet clutch

World produce the wet clutch. We use the best seals, bearing and friction discs. The wet cultch features lower noise and longer service life.

3.Double crankshafts

Double crankshaft piston totally eliminate side forces by reverse rotation. The bigger table and slide area is better for big sheet metal punching or bending etc.

4.High precision slider with hydraulic overload pump

The eight faces guide rails provide higher accuracy and stability. The hydraulic overload pump can protect the press and the die if overload. You can reset the overload pump by the touch screen easily. A thin brake motor is equipped on the slide to adjust the slide easily.

5.Easy and safe control

The control panel includes double hand buttons and emergency stop button. And foot pedal control switch is optional.

The touch screen includes the counter, crankshaft angle displayer, control switches and alarm lights. You can set the press with the touch screen and any defaults of the press can be checked with it.

Hydraulic overload protected pump is used to protect the press and the die if the machine is overloaded. You can reset the overload with the switch on the touch screen easily.

The press has both electric cam controller and mechanical cam controller. The mechanical cam controller can still work if the electric one stops service. And you can select the cam by the touch screen too.

6.Separate electric box

The press is equipped with a separate electric box to avoid the shocking influence. Famous brand PLC and contactors ensure better stability and reliability.

7.High precision processing equipment

The famous Pama brand boring and milling machine ensures the high precision of the press frame and slide.

Packaging

- Waterproof plastic film

- Pallet with plastic film

- Plywood box with plastic film

Shipping

- Transport by van to Shanghai port or your address

- Transport by air to your address

- Transport by sea to destination port

Pre-sales services

- Min.Order Quantity:1 set.

- Certicate: CE or ISO certificate.

- Lead time: some in stock, some half month

- OEM & ODM support

- Response in 12 hours

- 72 hours running test before delivery

After-sales services

- 24 hours hotline 0086-0553-7568159

- Online installation and operation instruction

- Onsite service fee: 100 dollars per day except air ticket and hotel

- Lifetime maintainence support

Warranty

- 1 year for main parts except accessaries.

- Do not cover wrong operation, careless maintenance, deliberate damage