2. Jacket heating and cooling function (steam/electric heating)

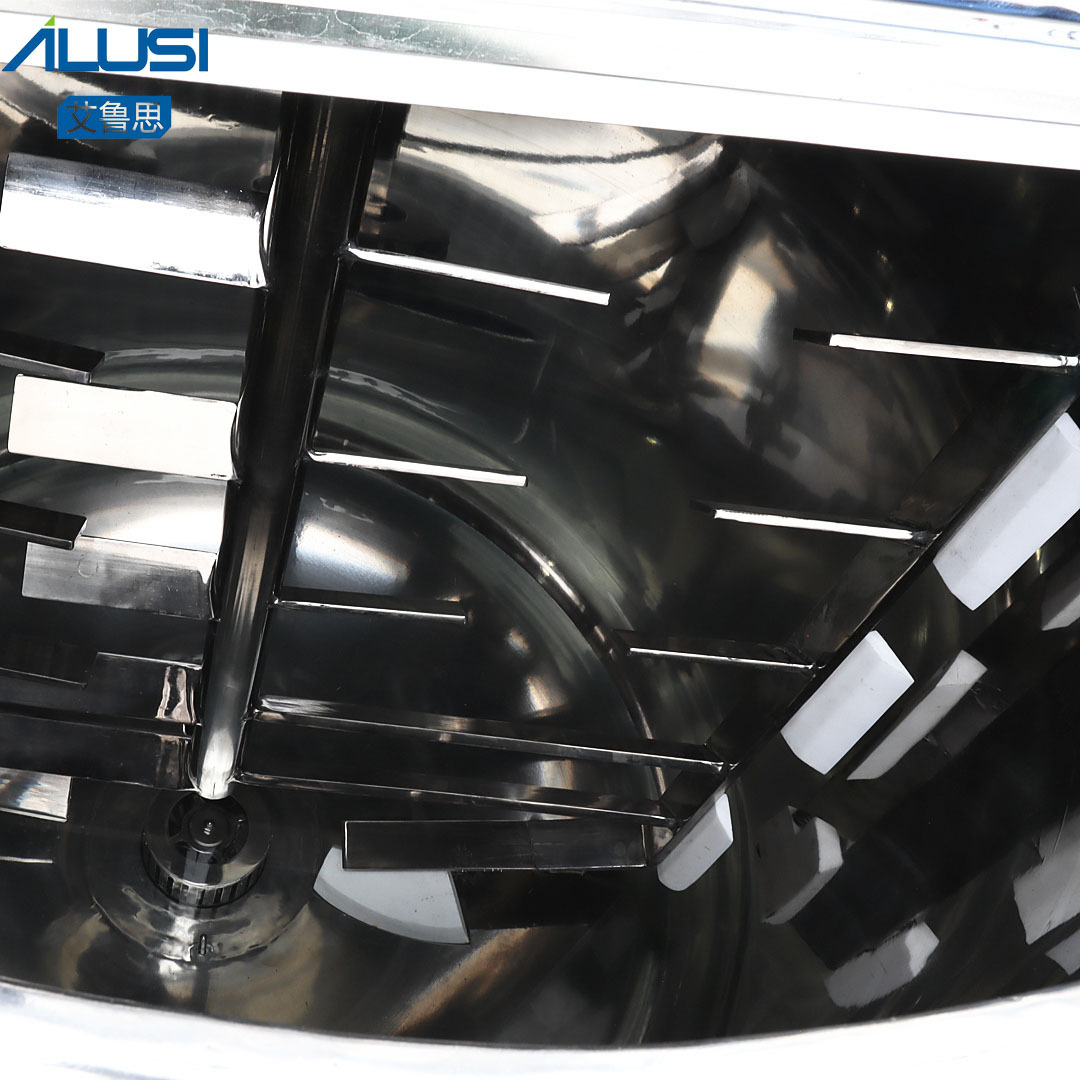

3. The pot body is welded by three layers of stainless steel plates, mirror polished, in line with GMP requirements.

4. High-speed shearing homogenizer 3600rpm, strong mixing of solid and liquid raw materials.

5. Schneider switch control button, Delta inverter, Omron temperature contro

3. The pot body is welded by three layers of stainless steel plates, mirror polished, in line with GMP requirements.

4. High-speed shearing homogenizer 3600rpm, strong mixing of solid and liquid raw materials.

5. Schneider switch control button, Delta inverter, Omron temperature contro