- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JCD

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

1600x900x1200mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

PE Stretch Film jumbo roll to small roll rewinding Machine

-

Keyword:

-

Stretch film rewinding machine

-

Shipping way:

-

by sea

-

Length counter:

-

automatic

-

Controlling:

-

inverter motor

-

Rewinding shaft:

-

double shafts

-

Operation:

-

Simple / 1 Person

-

Function:

-

Cling film jumbo roll to small roll rewinding

Quick Details

-

Voltage:

-

3 phase 380V/50HZ

-

Power:

-

4KW

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JCD

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

1600x900x1200mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

PE Stretch Film jumbo roll to small roll rewinding Machine

-

Keyword:

-

Stretch film rewinding machine

-

Shipping way:

-

by sea

-

Length counter:

-

automatic

-

Controlling:

-

inverter motor

-

Rewinding shaft:

-

double shafts

-

Operation:

-

Simple / 1 Person

-

Function:

-

Cling film jumbo roll to small roll rewinding

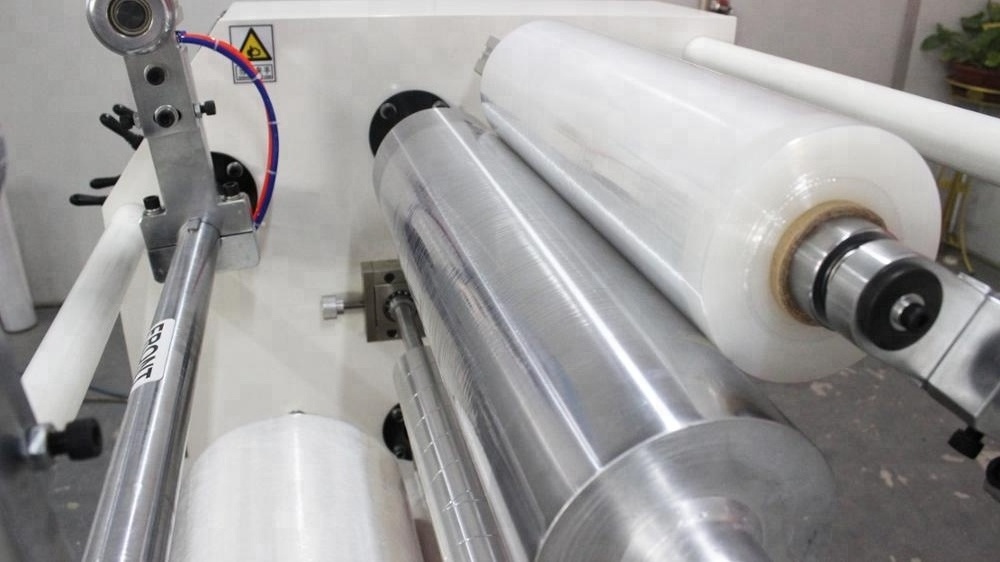

Strech film jumbo roll rewinding machine ( model JC-R05)

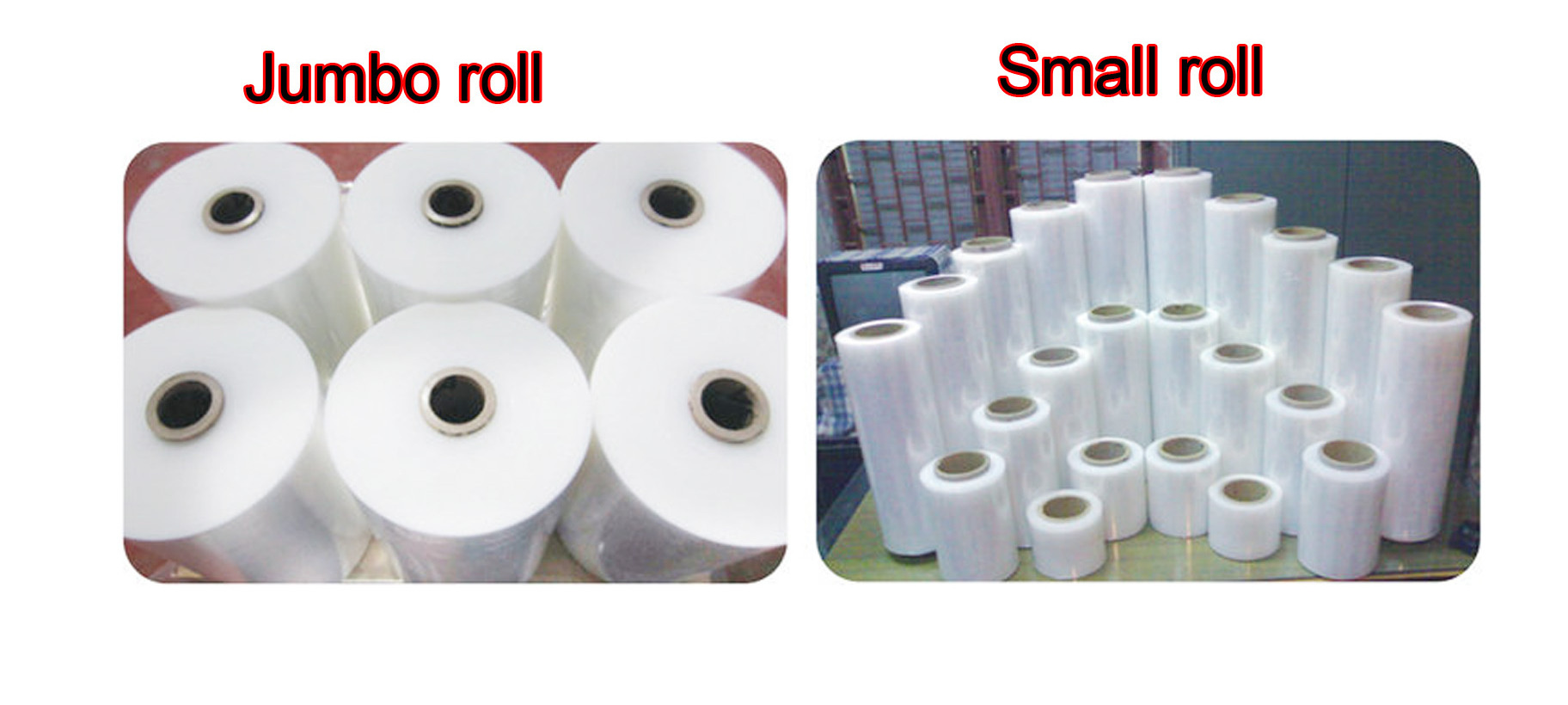

Function:

This machine is suitable for rewinding

This machine is suitable for rewinding the LLDPE stretch film,pallet stretch wrap, industrial stretch wrap,machine stretch

film,hand stretch film,bundling stretch film,food stretch wrapping film and PVC cling film etc.

film,hand stretch film,bundling stretch film,food stretch wrapping film and PVC cling film etc.

This machine is suitable for rewinding the LLDPE stretch film,pallet stretch wrap, industrial stretch wrap,machine stretch film,hand stretch film,bundling stretch film,food stretch wrapping film and PVC cling film etc.

Main Features

1) The machine adopts branded electrical control system. To ensure the good performance,easy to use and low noise.

2)The machine adopts upper and lower shafts winding, makes the loading and unloading is very convenient.

3) The machine winding tension can be adjusted of the belt.

4)Frequency control with constant rubber traction roller for machine speed.Ensure the rewinding speed more constant and steady.

5) The winding adopts two-stage automatic length counter.You can set up the request length in advance for automatic deceleration and stop. Ensure the accuracy of rewinding length.

6) Operating machine and finished roll packing only need one person. Simple operating and labor-saving.

Technical parameters

|

Roll width

|

600mm

|

|

Max.parent roll diameter

|

500mm

|

|

Max.rewind diameter

|

300mm

|

|

Rewind speed

|

700M/min

|

|

I.D of paper/plastic core

|

3''

|

|

I.D of sub-roll core

|

1''~3''

|

|

Roll laying way

|

By hand

|

|

Overall size

|

1600x900x1200mm

|

|

G.W

|

800kg

|

|

Power

|

4KW

|

|

Voltage

|

3 phase 380V/ 50HZ

|

Detailed Images

---PACKING & DELIVERY---

|

Packaging: WOODEN CASE

|

|

|

|

Packaging Details

|

A seaworthy wooden case for packing the whole machine.

No need do fumigation bcs it is a kind of plywood.

Convenient for the forklift operation during loading & unload in container.

|

|

|

Packaging: VACUUM PACKING

|

|

|

|

Packaging Details

|

We also provide vacuum packing for machine according to customers special request.

Avoid the electrical parts appliances during long distance transportation on the sea.

|

|

--- CE CERTIFICATION---

---OUR FACTORY---

---OUR EXHIBITION---

---FAQ---

---CONTRACT US---

Hot Searches