NanoMem® is an expert in ceramic membranes for separation and reaction; we provide the filtration membrane to meet various specific requirements. The annual production of our factory is one million square meters.

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Carton

-

Weight:

-

0.6kgs

-

Size:

-

510*150*4mm

-

Power:

-

/

-

Productivity:

-

50L/Hour

-

Weight (KG):

-

0.6 kg

-

Application:

-

Water treatment

-

Materials:

-

Alpha-Al2O3

-

Product name:

-

septic tank ceramic parts ceramic membrane housing

-

Frame:

-

SS304

-

Color:

-

White

-

Membrane area:

-

0.15m2

-

Dimension:

-

W150mmxH510mmxT4mm

-

Shape Type:

-

Square

-

Structure:

-

Open Cell Reticulated

-

Type:

-

Press Filter

Quick Details

-

Core Components:

-

flat ceramic membrane

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

NanoMem

-

Material:

-

Carton

-

Weight:

-

0.6kgs

-

Size:

-

510*150*4mm

-

Power:

-

/

-

Productivity:

-

50L/Hour

-

Weight (KG):

-

0.6 kg

-

Application:

-

Water treatment

-

Materials:

-

Alpha-Al2O3

-

Product name:

-

septic tank ceramic parts ceramic membrane housing

-

Frame:

-

SS304

-

Color:

-

White

-

Membrane area:

-

0.15m2

-

Dimension:

-

W150mmxH510mmxT4mm

-

Shape Type:

-

Square

-

Structure:

-

Open Cell Reticulated

-

Type:

-

Press Filter

Professional solution provider including graphite products, silicone pad, die-cutting, ceramic filtration membrane.

www.nanombr.com

|

Parameters of ceramic filtration membrane sheet

|

|

|

|

|

||||

|

Model

|

PCFM-A-20-3-U

|

PCFM-A-50-3-U

|

PCFM-A-100-3-U

|

PCFM-A-1U-3-M

|

||||

|

Formation

|

Plate

|

|

|

|

||||

|

Filtration

|

Negative pressure suction filtration

|

|

|

|

||||

|

Materials

|

Alpha-Al2O3

|

|

|

|

||||

|

Water channel, pcs

|

43

|

|

|

|

||||

|

Channel dimension, mm

|

2×3

|

|

|

|

||||

|

Dimension, mm

|

W150×H510×T4

|

|

|

|

||||

|

Weight (dry), kg

|

0.44

|

|

|

|

||||

|

Membrane area,m

2

|

0.15

|

|

|

|

||||

|

Max. Pressure, MPa

|

-0.1~0.3

|

|

|

|

||||

|

Temperature,℃

|

10~75

|

|

|

|

||||

|

Nominal pore size,µm

|

0.02

|

0.05

|

0.1

|

1

|

||||

|

Porosity, %

|

30%

|

34%

|

35%

|

40%

|

||||

|

Pure water flux

m3/(m2 . d) |

20

|

20

|

100

|

200

|

||||

|

Bending strength,MPa

|

80

|

70

|

70

|

70

|

||||

|

Note: If there are different requirements on membrane materials, membrane size,

filtration precision, please directly contact our sales. |

|

|

|

|

||||

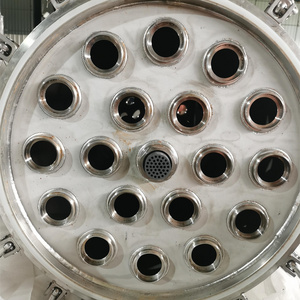

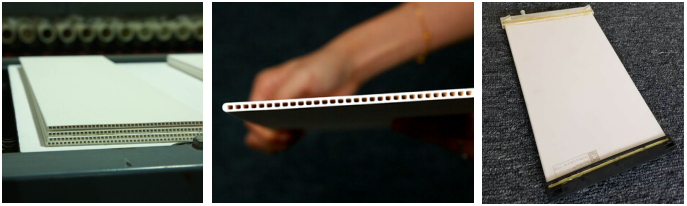

Pictures of ceramic filtration membrane sheet

Characteristics of ceramic membrane

★ Material excellent - high corrosion resistance, high strength, heat resistance, suitable for solvent or oil,

and suit for many kinds of drainage.

★ Long service life- the ceramic filter membrane system has a longer service life compared with the

hollow fiber membrane, so the full life cost is the lowest.

★Energy saving - the membrane surface is not easy to stain, and the replacement structure design.

★Maintenance free -automatic control system can reduce the daily maintenance.

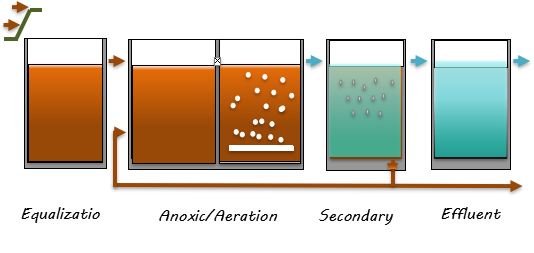

Membrane bioreactors (MBR) vs. conventional activated sludge (CAS) process.

Membrane comparison

Comparison of ceramic filtration membrane sheet, flat organic membrane, and the hollow fiber membrane.

|

|

Ceramic membrane (S)

|

Flat organic membrane

|

Fiber membrane

|

|

Area, m

2

|

50

|

177

|

266

|

|

Height, m

|

2

|

3.5

|

1.8

|

|

Floor space, m

2

|

0.3

|

1.8

|

0.81

|

|

Sewage flux, L/m

2

h

|

120

|

25

|

25

|

|

Daily capacity, ton/d

|

120

|

88.5

|

68.84

|

|

Volume capacity, ton/m

3

|

200

|

14.05

|

43.79

|

For example, the daily throughput 200ton/m3 system with the ceramic filtration membrane

has a great space advantage compared with that of the flat organic membrane or the hollow

fiber membrane system.

Due to high strength and corrosion resistance, ceramic membrane has many ways to regenerate

flux by such as aeration cleaning, backwashing, chemical backwashing and high-pressure flushing.

Comparison of membrane cleaning

|

Cleaning method

|

Ceramicmembrane (S)

|

Hollow fiber membrane

|

Flat organic membrane

|

Ceramic membrane (T)

|

|

Aeration cleaning

|

○

|

△

|

|

×

|

|

Backwashing

|

○

|

○

|

×

|

○

|

|

Chemical backwashing

|

○

|

○

|

×

|

○

|

|

High pressure cleaning

|

○

|

×

|

×

|

×

|

Aeration cleaning: because the structure of bubbles and ascending flow function is effectively

used, the sludge adhesion on membrane can be prevented with the minimum air volume.

Backwash: reduce clogging (increase in membrane pressure).

Chemical backwashing: good chemical resistance and no deterioration of membrane.

High-pressure cleaning: high-pressure water can remove the solid fouling on the membrane.

Product parameters

Micrograph of ceramic membrane

Through different production processes can be made into symmetric- and asymmetric- type

ceramic filtration membrane. The pore structure of ceramic filter membrane can be

obtained through pore size control.

Pore distribution of ceramic filtration membrane sheet

Trans-membrane pressure

The relationship between flux and pressure, the flux can be quickly recovered by simple cleaning.

Moreover, the trans-membrane pressure (TMP) of the ceramic filter membrane is 50% lower than that of the organic membrane.

Trans-membrane pressure (TMP) recovery of ceramic membrane

Hydrophilic

Ceramic materials are inherently hydrophilic, less wetting than water, and water spreads on the surface of ceramic membrane, which is more conducive to sewage separation than organic materials.

SHydrophobic membrane Hydrophilic membrane

Water temperature calibration

For application with large temperature variations, temperature correction should be taken in consideration. The calibration coefficient is set to 1 at 25℃. The calibration coefficient is read out from Figure 1-8 according to the actual design temperature. The actual design flux is the product of nominal flux at 25℃ and temperature correction coefficient.

Calibration curves of water temperature and flux for ceramic membrane

1)Sewage treatment (Petroleum sewage treatment, oily wastewater treatment, industrial sewage treatment, landfill leachate

treatment, municipal sewage treatment, rural domestic sewage treatment, aquaculture wastewater treatment)

2)Upgrading and reconstruction of sewage treatment

3)Waste water recycling and reuse

4)Drinking water purification

5)Aquaculture water purification

6)Seawater desalination pretreatment

7)Fine separation of pharmaceuticals and pharmaceuticals

8)Filtration and purification of food processing

9)Air purification

10)Purification of new materials

ISO9001-2015, ISO14001-2015, IATF16949-2016, UL

We obtained more than 30 invention patents and utility model patent and gained the honor: "scientific and technological innovation enterprises", "Jiangxi Province special new enterprises", "national high-tech enterprises".

DSN adheres to

Taiji culture

of respecting social and loving people, fulfilling social responsibility, publicizing the environment and development, and realizing the common growth of society, enterprises and employees.

As Heaven's movement is ever vigorous, so must a gentleman ceaselessly strive along. DSN will work hard to press ahead and create new splendor.

Q1: What is your term of payment?

A1: Amount ≤1000USD, 100% in advance.

Amount≥1000USD, 30% T/T in advance, balance before shipment.

Q2: How about your delivery time?

A2: within 20 to 30 days after confirming all the details

Q3: Do you test all your goods before delivery?

A3: Yes, we do test before delivery.

Q4: Any warranty?

A4: One year since the date of delivery. If there is any wearing part broken within the warranty not caused by improperly operation, we would offer the new parts for free.

Q5: How do you keep long-term business relationship?

A5: 1. Nice quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service including after-sale service.