Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

1450 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONGSAN

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

15m*1.6m*2.5m

-

Power (kW):

-

160

-

Weight:

-

2-5T

-

Name:

-

PVC double wall bellows tube making machine

-

Extrusion line:

-

double wall corrugated extrusion line

-

Corrugated type:

-

DWC pipe making machine

-

Pipe diameter:

-

50-250mm

-

Product Speed:

-

0.5-5m/min

-

Product Tcapacity:

-

250-530kg/h

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

Temperature controller:

-

Omron Brand

-

Power:

-

55kw

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Turkey, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, India, Mexico, Russia, Spain, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

CE

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw diameter (mm):

-

90 mm

-

Screw Speed (rpm):

-

1450 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONGSAN

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

15m*1.6m*2.5m

-

Power (kW):

-

160

-

Weight:

-

2-5T

-

Name:

-

PVC double wall bellows tube making machine

-

Extrusion line:

-

double wall corrugated extrusion line

-

Corrugated type:

-

DWC pipe making machine

-

Pipe diameter:

-

50-250mm

-

Product Speed:

-

0.5-5m/min

-

Product Tcapacity:

-

250-530kg/h

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

Temperature controller:

-

Omron Brand

-

Power:

-

55kw

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Turkey, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, India, Mexico, Russia, Spain, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

CE

-

Marketing Type:

-

Hot Product 2019

Product Description

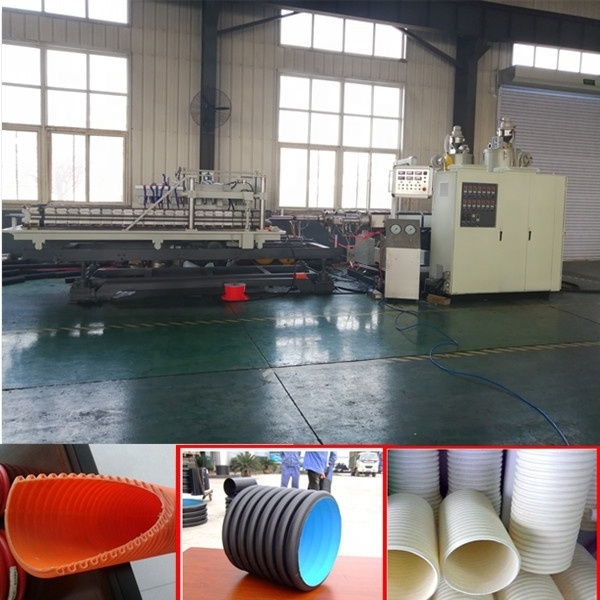

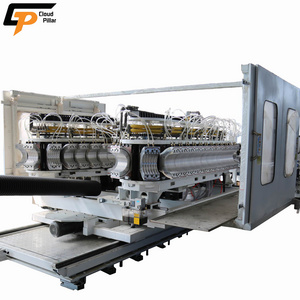

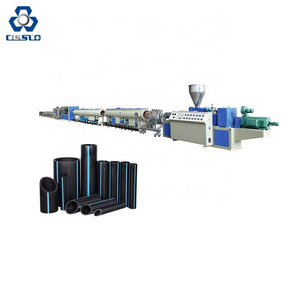

40-300mm Horizontal CE Certificated HDPE Double wall corrugated DWC pipe machine with Aluminum mold

PE/HDPE/PVC double wall corrugated pipe extrusion line adopts extruding and forming process, it has the featuresof reliable quality and high efficiency.Compared with other plastic pipe wall structure ,double wall corrugated pipe has excellent wall structure design,its low weight reach the lower production cost and improve the market competitiveness.The pipe is widely used in various field instead of concrete pipe and iron pipes,because it has excellent features such as:easy connected and accessiories installed,and quality reliable.

Technical details for the double wall DWC corrugated pipe machine:

|

Model

|

SBG110

|

SBG250

|

|

Pipe diameter (mm)

|

DN/ID 40-110

|

DN/ID 110-250

|

|

Die head,mould

|

40-110mm

|

110-250mm

|

|

Forming machine model

|

SBGC-110

|

SBGC-250

|

|

Spray cooling tank

|

SGL-110

|

SGL-250

|

|

Non-dust cutting machine

|

SGQ-110

|

SGQ-250

|

|

Stacker

|

SGD-250

|

SGD-500

|

|

Production capacity(kg/h)

|

PE:160

|

PE:230

|

|

Mold quantity(pair)

|

72

|

72

|

|

Product speed

|

3-4 m/min

|

2-3 m/min

|

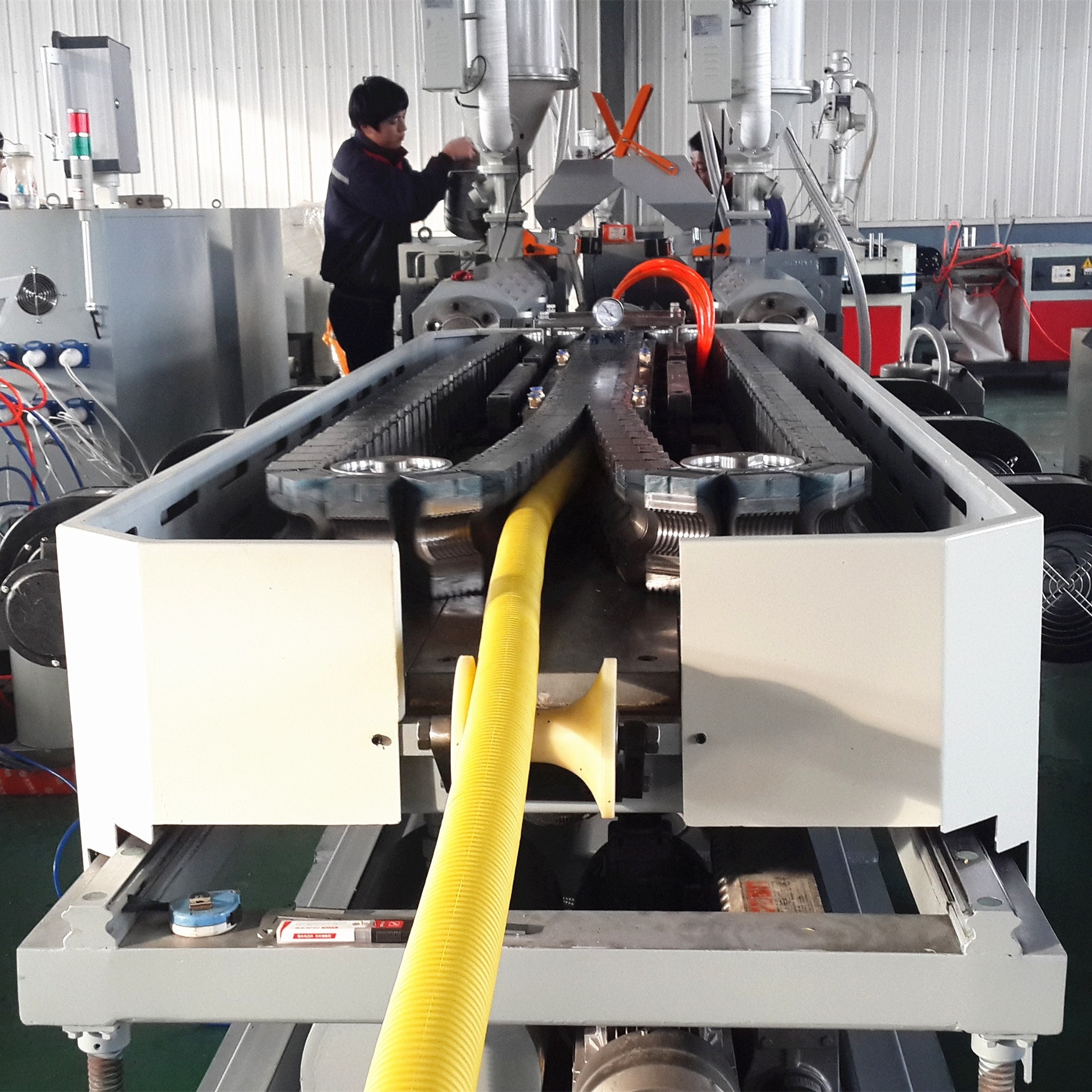

40-110mm DWC pipe machine

50-250mm DWC pipe machine

Advantage of our Plastic DWC double wall corrugated pipe machine

1. The main machine adopts special designed high efficiency screw which is specially used for polyolefin,it has the features of stable performance and high effiency.The machine has two independence extruders,which can realize both inside and outside layer with different material and colors.

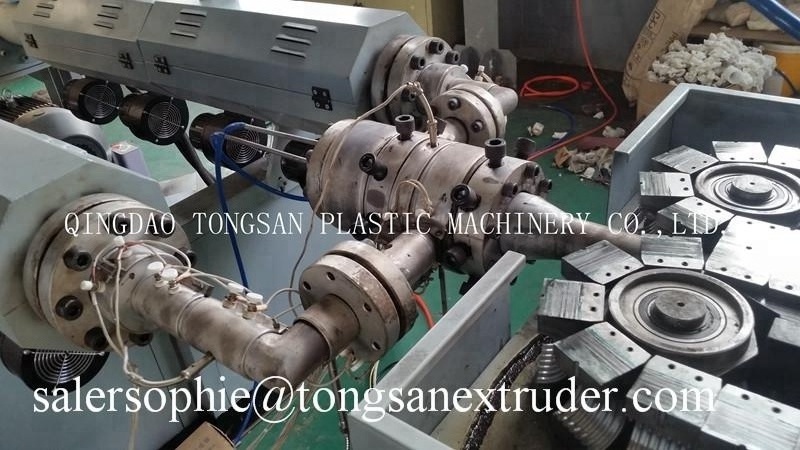

2. Composite extrusion die head with specially helical structure to make the wall thickness unifom and stable production.

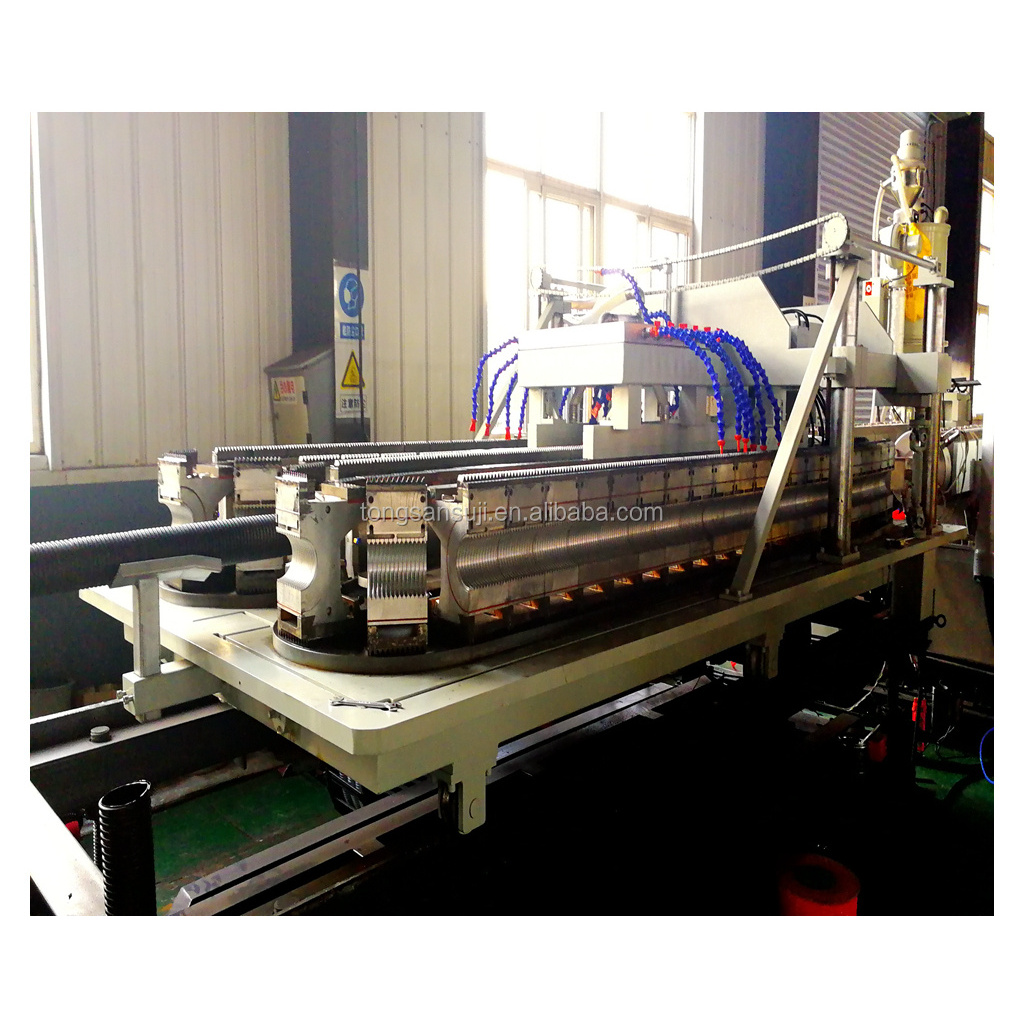

3. The forming machine has automatic power-off protection device.The forming machine an antomatically exit from the die head to avoid equipment failure in case of electrucity cut off suddenly.It also equipped with new type high transmitting ratio reducer, easy to operate and mainteance.

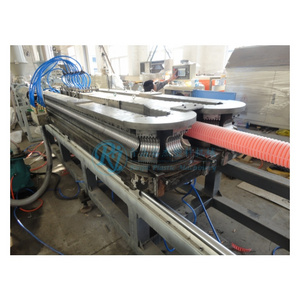

4. The corrugated forming system is in combination with water cooling and air cooling to sensure high production speed

continuously.Advanced programmable lubricating system minimizes the moulds wear so as to increase the life of service and ensure work smmothly with high precision to ensure the products quality stability.

5. Mould adopts specialy alumium alloy material and high precision die casting forming mould method,it has the advanages of high precision,high stremgth,good wearability and better heat dissipation performance.

6. Wave structure launched a comprehensive new optimization design to reach the best combination of high-rigidity and low weight.

2. Composite extrusion die head with specially helical structure to make the wall thickness unifom and stable production.

3. The forming machine has automatic power-off protection device.The forming machine an antomatically exit from the die head to avoid equipment failure in case of electrucity cut off suddenly.It also equipped with new type high transmitting ratio reducer, easy to operate and mainteance.

4. The corrugated forming system is in combination with water cooling and air cooling to sensure high production speed

continuously.Advanced programmable lubricating system minimizes the moulds wear so as to increase the life of service and ensure work smmothly with high precision to ensure the products quality stability.

5. Mould adopts specialy alumium alloy material and high precision die casting forming mould method,it has the advanages of high precision,high stremgth,good wearability and better heat dissipation performance.

6. Wave structure launched a comprehensive new optimization design to reach the best combination of high-rigidity and low weight.

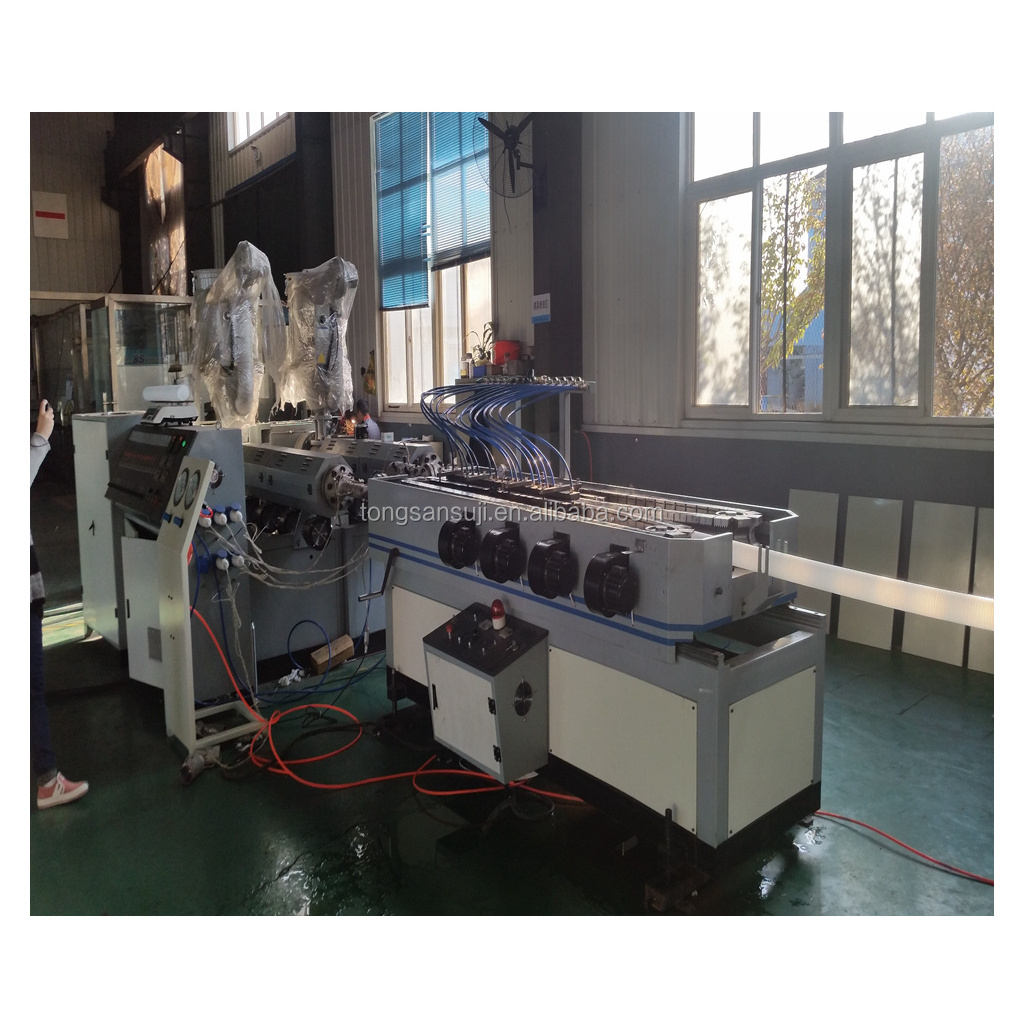

Detailed Images

Equipment list and machine details for 40-110mm DWC pipe machine

Single screw extruder SJ65/33

Single screw extruder SJ65/30

Double wall corrugated die head

45# Steel mold: 72 pairs

40-110mm Vacuum forming machine

forming machine with air cooling

Pull off machine

Auto cutting machine

Winding machine

Product stacker

Equipment list for the 50-250mm double wall DWC corrugated pipe machine:

|

Machine name

|

quantity

|

|

Automatic loader

|

2 sets

|

|

SJ90/33 extruder

|

1 set

|

|

Automatic loader

|

1 set

|

|

SJ75/30 extruder

|

1 set

|

|

Die head

|

50-250mm

|

|

Mould

|

50-250mm

|

|

Forming machine (water and vacuum synchronization)

|

1 set

|

|

cutting machine

|

1 set

|

|

6m stacking machine

|

1 set

|

Extruder for Double wall corrugated DWC pipe machine

Die head

Mold blocks

Mold for DWC double wall corrugated pipe machine

48 pairs, Aluminum material, inner hollow with water cooling channel, with vacuum cooling

Forming machine for DWC double wall corrugated pipe machine:

Automatic chipless cutter

Automatic single position winder

Related products

Our service

INSTALLATION AND COMMISSIONING

WE WILL SEND THE TECHNICIAN TO BUYER'S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE, AND OUR ENGINEER WILL DO TRAINNING TO BUYER'S WORKERS UNTIL THEY CAN RUN OUR MACHINE FOR STABLY PRODUCTION

AFTER SELL SERVICE: ONE YEAR GUARNTEE, FOREVER SERVICE!

WITHIN THE GUARANTEE OF ONE YEAR, WE WILL PROVIDE EFFICIENT AND ON TIME MAINTAINS,IF ANY SPARE PARTS DAMAGED IN THE GUARANTEE TERM BECAUSE OF QUALITY PROBLEM, WE WILL PROVIDE NEW SPARE PARTS FOR FREE FOR REPLACMENT.

Turnkey project service:

1, we will provide all the machines for the complete production according to customer's requirements.

2, we will provide complete service for factory layout and other informations to help customer to build the factory.

3, we can also provide the raw material to the customer if you need.

4, we will provide good service for machine installation and trainning, until the customers can run the machines and make stably production.

5, Except one year quality guarantee,we will provide after-sell service for all the life.

6, for long-term cooperation, we always provide good quality, good price and good service to customer. we are the professional and trustable supplier for turnkey projects. let us do win-win business together.

Product packaging

Company profile

Certifications

Customer Photos

FAQ

Hot Searches