- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Kenli

-

Keyword:

-

Kenli OEM aluminum water cooling block water liquid cooling plate

-

Material:

-

Aluminum alloy

-

Tube material:

-

Copper

-

Working pressure:

-

1.2 to 5 bars

-

Surface flatness:

-

Below 0.05mm

-

Deep processing:

-

Punching Driling Precison Cutting CNC

-

Cooling method:

-

Liquid

Quick Details

-

Type:

-

Heat Exchanger Tube

-

Application:

-

Heater Parts

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Kenli

-

Keyword:

-

Kenli OEM aluminum water cooling block water liquid cooling plate

-

Material:

-

Aluminum alloy

-

Tube material:

-

Copper

-

Working pressure:

-

1.2 to 5 bars

-

Surface flatness:

-

Below 0.05mm

-

Deep processing:

-

Punching Driling Precison Cutting CNC

-

Cooling method:

-

Liquid

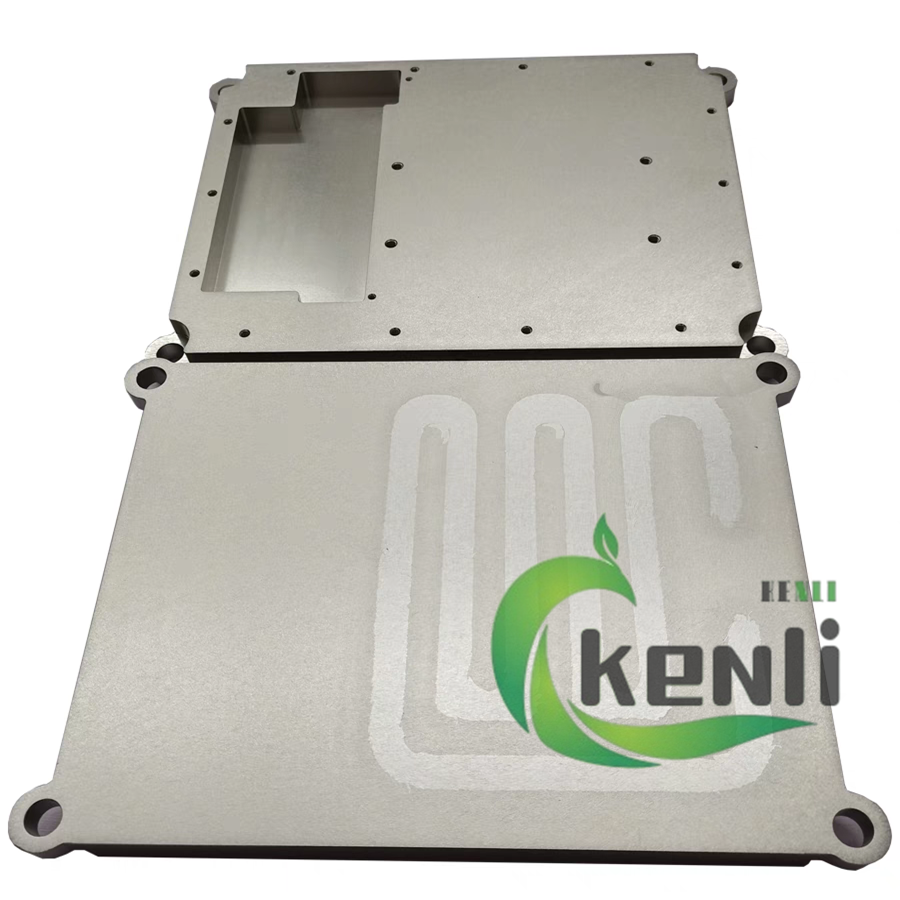

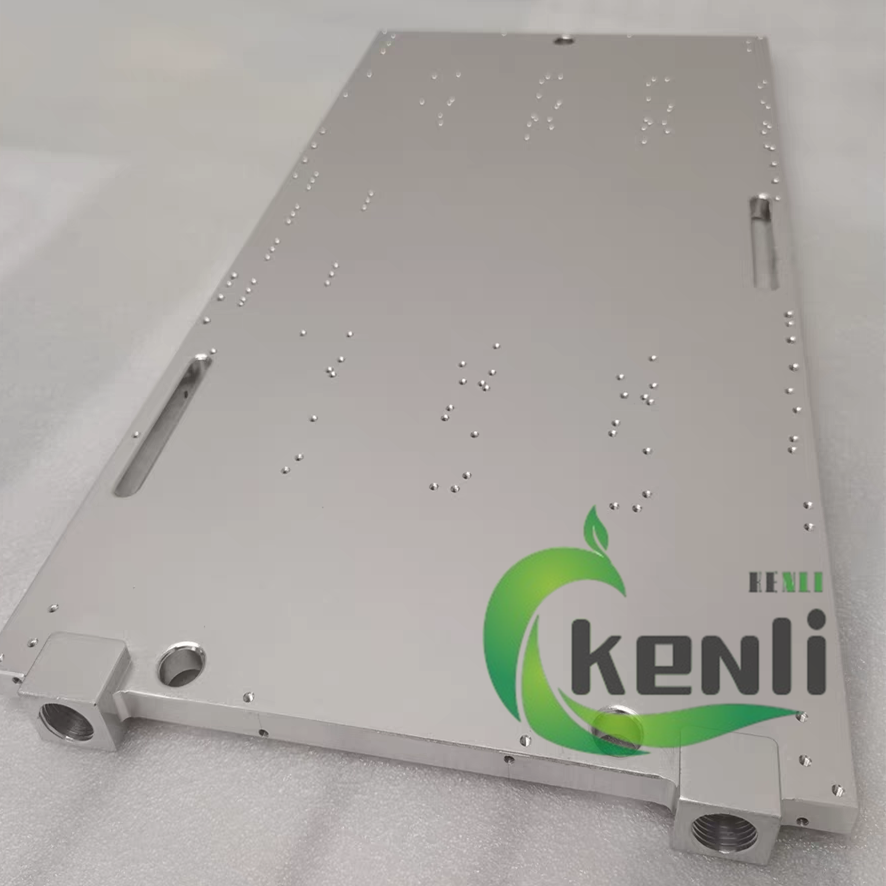

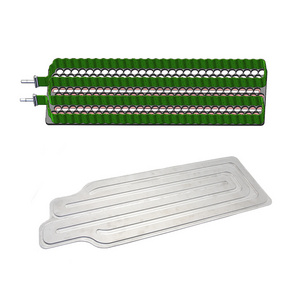

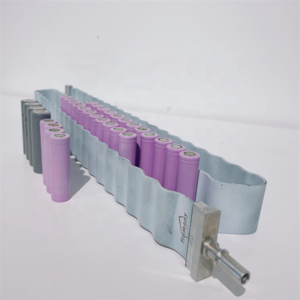

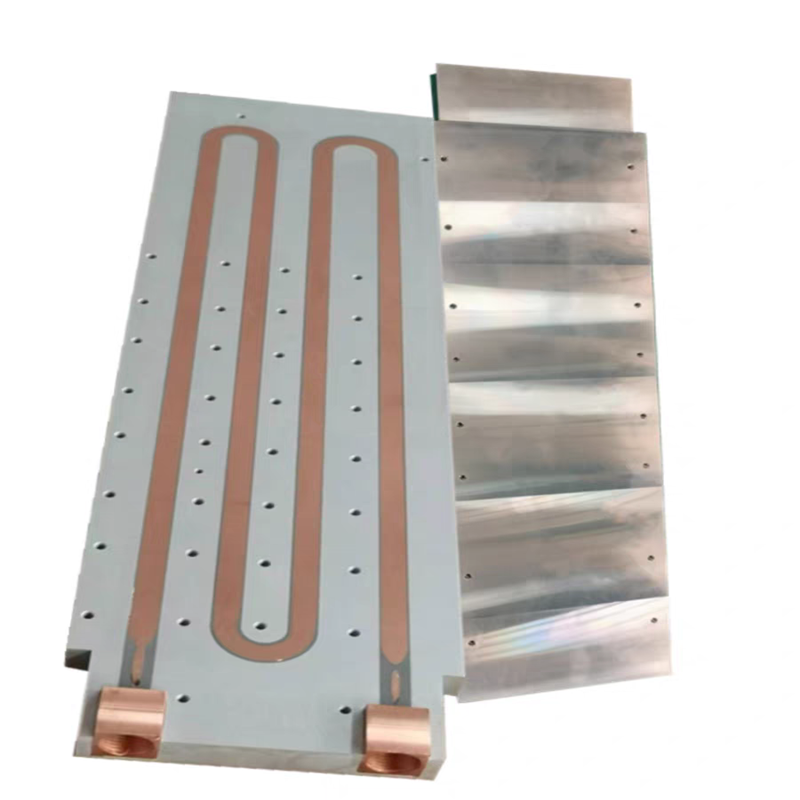

Custom liquid cool plate with various channel

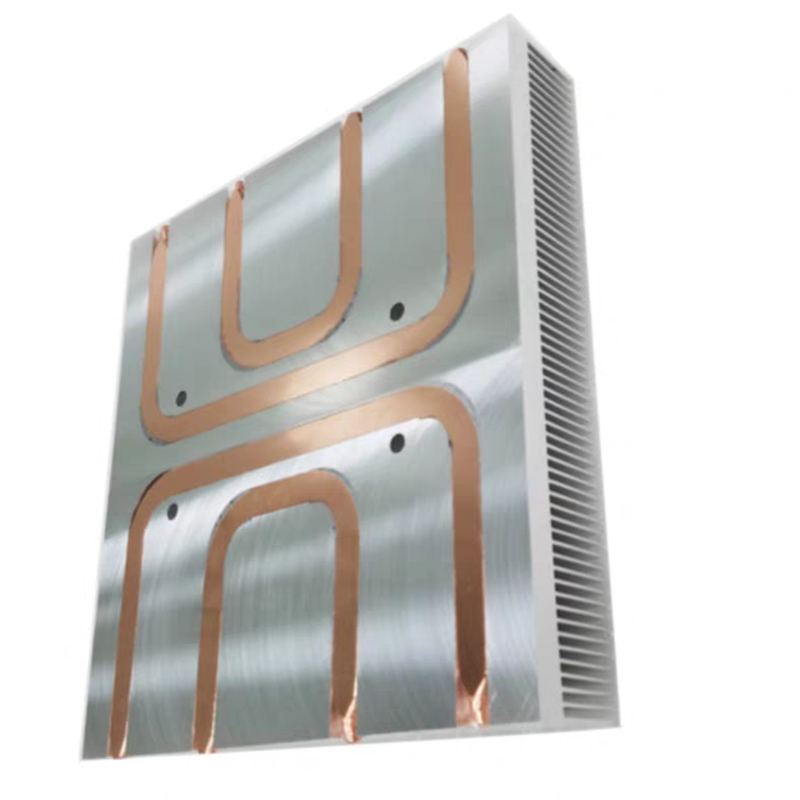

Skived Fin Heat Sink With Heat Pipe

Rolled Boned Liquid Cold Plates With Channels Blown Up Micro Channel

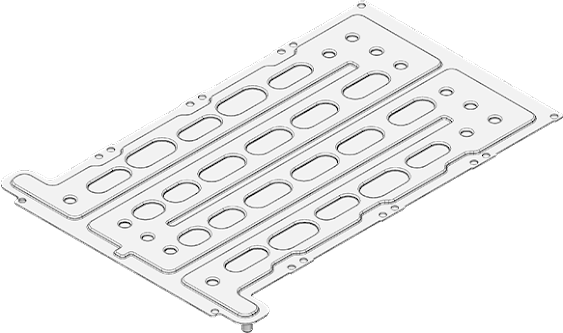

Extruded Liquid Cold Plate

Liquid Cold Plates With Channels

Friction Stir Welding

Liquid Cold Plates Product

|

Item

|

Liquid cooling plates With FSW/Brazing

|

|

Material

|

Aluminum Alloy

|

|

Size

|

As per customers' design

|

|

Application

|

Electronic Industry,Thermo electric Coolers,IGBT Cooling Systems and power device etc

|

|

Production Process

|

Aluminum Plate Cutting--Grooves Making--Embedding Tubes(Friction Stir Welding)--Epoxy adhesive filling--CNC Machining--Cleaning--Inspecting--Packing

|

|

Machining

|

CNC,drilling,milling,cutting,welding,bending,assembling

|

|

Surface Treatment

|

mill, anodized,powder coated,electrophoresis,wood grain,polish,brushed

|

|

Packing Detail

|

Inside: packed with plastic film to protect each piece Outside: by waterproof craft paper or EPE film in wooden case

|

|

Production Capacity

|

4200000 pieces each month annually.

|

|

MOQ

|

1PC

|

Designing and manufacturing cold plate cooling systems and heat exchangers for the most demanding thermal management applications.

Liquid Cooled Chassis

To compare various heat exchangers and make informed decisions, it is important to consider the advantages and disadvantages of each product and perform a cost-benefit analysis. An essential factor in this regard is operational safety and stability, allowing the company to save energy and use heat exchanger products more economically.

Our expertise extends from the production of complex tooling, to the production of individual components, to the machining of individual parts to customer specifications. Qualified processing and production of small batches is part of our service range.

appearance and functionality!

Finest tolerances and high decorative surfaces!

Our offer is adaptable to combine your requirements and our ideas.

QUALITY CONTROL

Professional measure tools at every aspect size,

trimos, microscopes,hardness

,surface film,physical property,loading weight.

Aluminum components for new energy vehicles include automobile chassis and anti-collision beam

Requirements for aluminum alloy profiles with excellent performance for vehicles: the compressive strength is getting higher and higher, the concave die is getting more and more complicated, and the wall thickness is getting thinner and thinner.

Sheet Metal Fabrication

Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining.

Not sure what to get? Consult our sales team for assistance!

Custom Designed Heat Dissipation Solutions By KENLI

Or We Can Collaborate On Your Design

or Let Us Manufacturer Your Design

Just Send Your CAD Drawings

Packing & Delivery

(Shrink film/Single Plastic Bag+waterproof kraft paper+wooden case)

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches