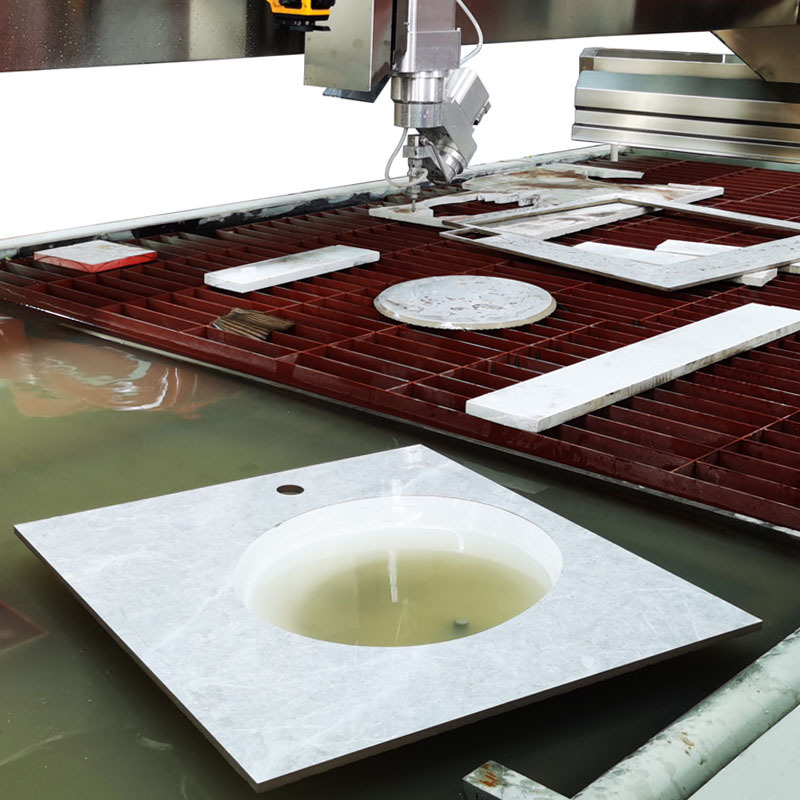

1) Processable any curve cutting, flexible, convenient and versatile.

2) Notch is fast and smooth, no dust, no thermal deformation and no pollution.

Tension-free processed parts due to minimal cutting force.

3) Narrow kerf – The amount of material removed by the water jet stream is typically about 0.5-1.0 mm wide. Cut width optimizes material use, increasing cost effectiveness.

4)

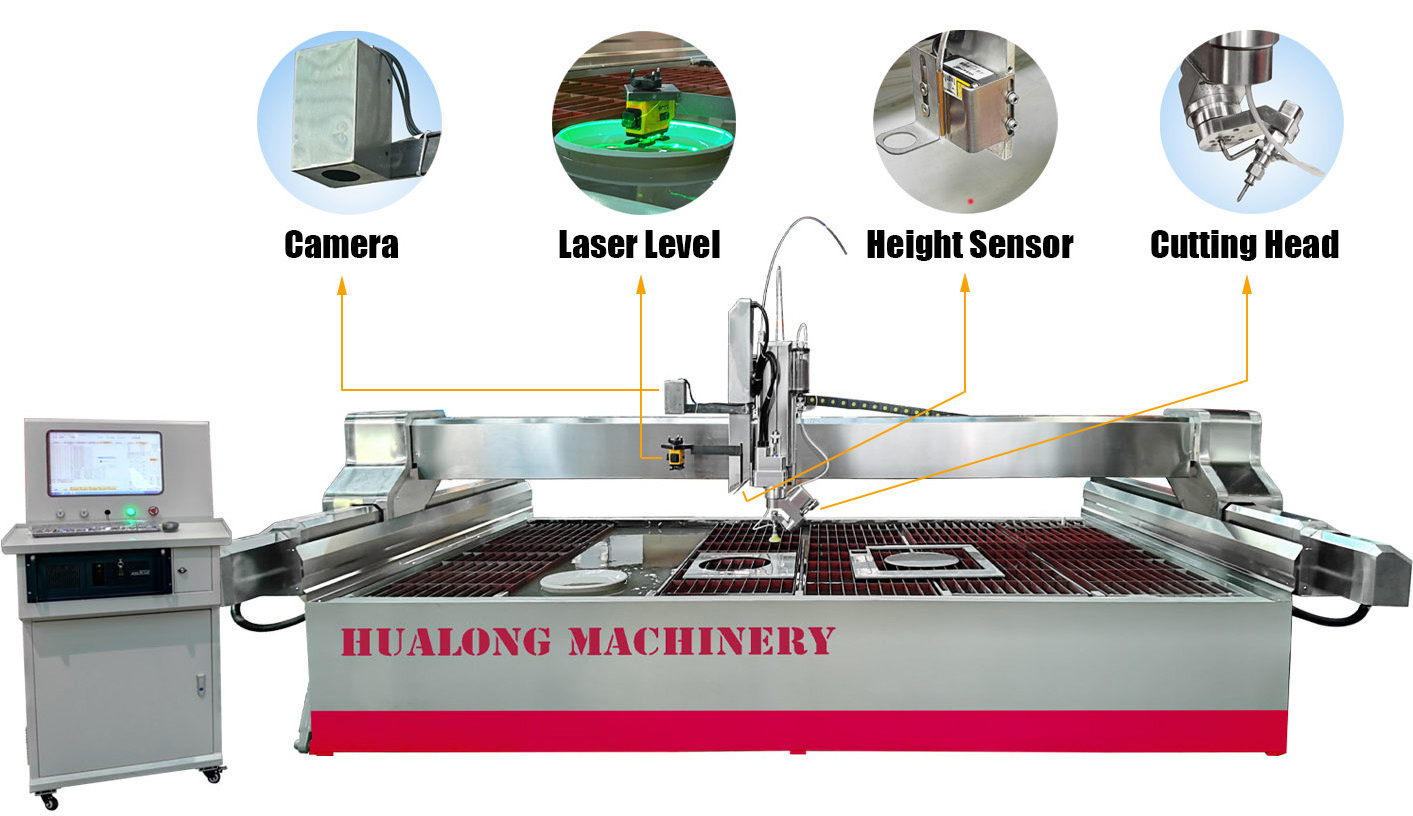

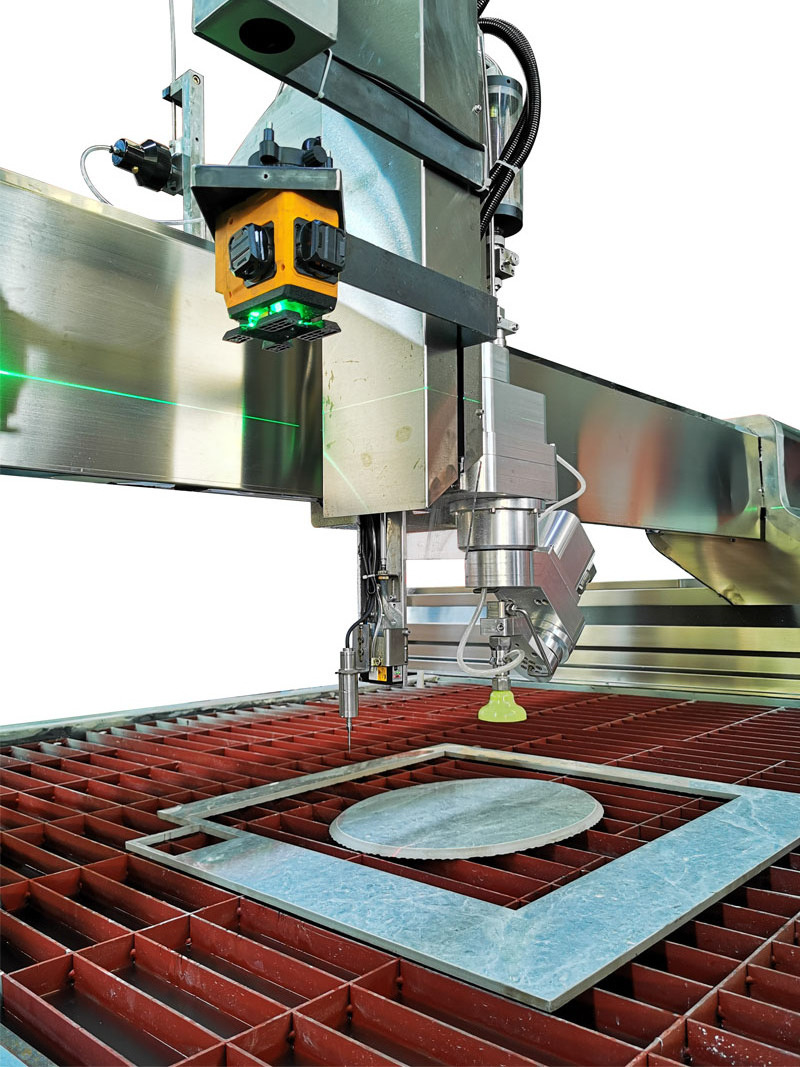

Cut Recovery - Pick back up where Jet stopped.

5)

Programmable Z axis height. Z axis retracts between pierces.

6) Servo motor, linear sledge and vehicles, helical rack and pinions is used for providing a rapid and smooth axial movement.

7) High-Performance drive system, which permit high-precision production of parts as well as the highest processing speed.

8) Driver system sealed against water,dust and grit. Long working life.

6) Servo motor, linear sledge and vehicles, helical rack and pinions is used for providing a rapid and smooth axial movement.

7) High-Performance drive system, which permit high-precision production of parts as well as the highest processing speed.

8) Driver system sealed against water,dust and grit. Long working life.