- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

1 - 12000

-

Positioning Accuracy (mm):

-

0.003

-

Repeatability (X/Y/Z) (mm):

-

0.005

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SOSEN

-

Model Number:

-

vmc850

-

Table Travel (mm):

-

800*500*500mm

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

2750 * 2300 * 2300mm

-

Weight (KG):

-

5300

-

Spindle Motor Power(kW):

-

7.5

-

Max. Table Load(kg):

-

600 kg

-

Marketing Type:

-

New Product

-

Table area:

-

1000*500mm

-

T slot:

-

3*18*80mm

-

The spindle taper hole:

-

BT40

-

Spindle speed:

-

8000rpm

-

Spindle power:

-

7.5 KW

-

Distance from spindle to table:

-

105-655mm

-

CNC Controller System:

-

GSK980

-

Positioning accuracy:

-

0.003

-

Repeat positioning accuracy:

-

0.005

Quick Details

-

Table Travel (X) (mm):

-

800

-

Table Travel (Y) (mm):

-

500

-

Table Travel (Z) (mm):

-

500

-

Range of Spindle Speed(r.p.m):

-

1 - 12000

-

Positioning Accuracy (mm):

-

0.003

-

Repeatability (X/Y/Z) (mm):

-

0.005

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SOSEN

-

Model Number:

-

vmc850

-

Table Travel (mm):

-

800*500*500mm

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

2750 * 2300 * 2300mm

-

Weight (KG):

-

5300

-

Spindle Motor Power(kW):

-

7.5

-

Max. Table Load(kg):

-

600 kg

-

Marketing Type:

-

New Product

-

Table area:

-

1000*500mm

-

T slot:

-

3*18*80mm

-

The spindle taper hole:

-

BT40

-

Spindle speed:

-

8000rpm

-

Spindle power:

-

7.5 KW

-

Distance from spindle to table:

-

105-655mm

-

CNC Controller System:

-

GSK980

-

Positioning accuracy:

-

0.003

-

Repeat positioning accuracy:

-

0.005

Product Description

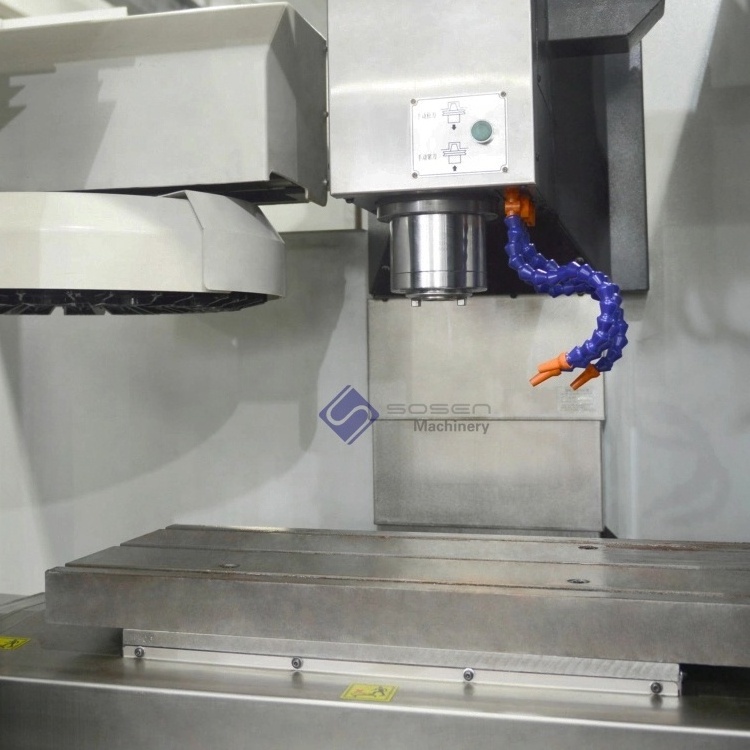

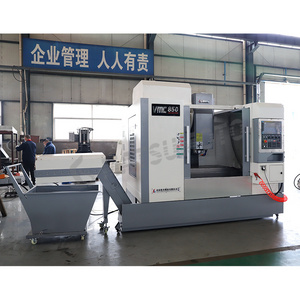

VMC850 China vertical machining center fully protected 5 axis CNC milling machine

Main features:

1. CNC VMC 850 vertical milling machining centre basic parts such as base, sliding seat, workbench, column and headstock are made of HT300 cast iron; the base is box-type structure, and the compact and reasonable symmetrical structure ensures the high rigidity and bending resistance of the foundation. The A-type bridge straddle column and the internal grid-shaped ribs ensure the rigidity and precision of the Z-axis strong cutting; the base parts are resin sand molding and aging treatment, which guarantees the stability of the long-term performance of the machine tool.

2. The X, Y and Z three-way guide rails are Taiwan's ball linear guides, which have the characteristics of high speed, high

rigidity, low friction, low noise, low temperature rise and other characteristics, and cooperate with automatic forced lubrication to improve the precision life of the machine tool;

3, Z-direction plus weight balance, to ensure smooth and stable headstock movement; Z-direction drive motor has power-off braking device;

4. The X, Y and Z directions are fed with high precision and high strength inner loop double nut preloading large lead ball screw, and the feed speed is high; the drive motor is directly connected with the lead screw through the elastic coupling. The feed servo motor directly transmits the power to the high-precision ball screw without backlash, ensuring the positioning accuracy and synchronization of the machine tool;

5, the use of high-speed, high-precision, high-rigidity spindle unit, axial and radial bearing capacity, the highest speed up to

8000rpm;

6. The main shaft adopts the central air blowing structure. When the main shaft is loosened, the central high-pressure gas is quickly used to clean the inner cone of the main shaft to ensure the precision and life of the tool clamping.

7. X, Y, Z three-direction guide rails and lead screws are equipped with protective devices to ensure the cleanliness of the lead screws and guide rails, ensuring the transmission and movement accuracy and life of the machine tools;

8. The outer protection of the machine tool adopts the full protective structure design, which is convenient to operate, safe and reliable, and beautiful and generous;

9. Adopt reliable centralized automatic lubrication device, and automatically and intermittently lubricate the lubrication points of the machine tool regularly and quantitatively, and adjust the lubrication time according to the working condition;

2. The X, Y and Z three-way guide rails are Taiwan's ball linear guides, which have the characteristics of high speed, high

rigidity, low friction, low noise, low temperature rise and other characteristics, and cooperate with automatic forced lubrication to improve the precision life of the machine tool;

3, Z-direction plus weight balance, to ensure smooth and stable headstock movement; Z-direction drive motor has power-off braking device;

4. The X, Y and Z directions are fed with high precision and high strength inner loop double nut preloading large lead ball screw, and the feed speed is high; the drive motor is directly connected with the lead screw through the elastic coupling. The feed servo motor directly transmits the power to the high-precision ball screw without backlash, ensuring the positioning accuracy and synchronization of the machine tool;

5, the use of high-speed, high-precision, high-rigidity spindle unit, axial and radial bearing capacity, the highest speed up to

8000rpm;

6. The main shaft adopts the central air blowing structure. When the main shaft is loosened, the central high-pressure gas is quickly used to clean the inner cone of the main shaft to ensure the precision and life of the tool clamping.

7. X, Y, Z three-direction guide rails and lead screws are equipped with protective devices to ensure the cleanliness of the lead screws and guide rails, ensuring the transmission and movement accuracy and life of the machine tools;

8. The outer protection of the machine tool adopts the full protective structure design, which is convenient to operate, safe and reliable, and beautiful and generous;

9. Adopt reliable centralized automatic lubrication device, and automatically and intermittently lubricate the lubrication points of the machine tool regularly and quantitatively, and adjust the lubrication time according to the working condition;

|

CNC VMC 850 vertical milling machining centre

|

VMC850

|

|

Worktable size

|

1000*500mm

|

|

Max.loading capacity of worktable

|

600kg

|

|

Worktable travel X*Y*Z

|

800*500*500mm

|

|

Distance between spindle nose to table

|

105-655mm

|

|

Distance between spindle centre to column surface

|

550mm

|

|

Rapid moving speed X/Y/Z

|

20/20/18m/min

|

|

Cutting feeding speed X/Y/Z

|

1-10000mm/min

|

|

Spindle taper

|

BT40

|

|

Max.spindle speed

|

8000rpm

|

|

Spindle motor power

|

7.5kw

|

|

Position accuracy

|

0.01mm

|

|

Re-position accuracy

|

0.003mm

|

|

Automatic Tool magazine pieces

|

16 pcs

|

|

Max.tools weight

|

8 kg

|

|

Max.tools size

|

80*300mm

|

|

Time of tool changing

|

2.5 s

|

|

Overall size

|

3000*2500*2750mm

|

|

Machine weight

|

5300 kg

|

Details Images

Product packaging

Packing & Delivery

Hot Searches