Neodymium magnet, the third generation of the rare-earth permanent magnet, is the most powerful and advanced permanent magnet

today. Neodymium is named as"Magnet King" for its high remanence, high energy. Moreover, it has the high performance and high-cost

ration, because of the rich rare earth resources in China and the ever-changing production process and technological progress. It

can be easily formed into various sizes and different shapes, such as segment, ring, block, etc.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

Model Number:

-

N35-N52 (M.H.SH.UH.EH.AH)

-

Product Name:

-

Neodymium Magnet

-

Material:

-

Permanent Neodymium Magnet

-

Certification:

-

ISO9001,ROHS

-

Coating:

-

Ni-Cu-Ni, Ni, Customized

-

Size:

-

Customized Magnet Size

-

Color:

-

Bright Silver, Customized

-

Shape:

-

Accept Customs

-

Density:

-

7.5-7.6 g Per Cubic Centimetre

-

Sample:

-

Free Sample

-

Packing:

-

Magnetic Isolation Package

Quick Details

-

Tolerance:

-

±0.5%

-

Grade:

-

Neodymium Magnets, N35-N52- NSH/customized

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

OEM

-

Model Number:

-

N35-N52 (M.H.SH.UH.EH.AH)

-

Product Name:

-

Neodymium Magnet

-

Material:

-

Permanent Neodymium Magnet

-

Certification:

-

ISO9001,ROHS

-

Coating:

-

Ni-Cu-Ni, Ni, Customized

-

Size:

-

Customized Magnet Size

-

Color:

-

Bright Silver, Customized

-

Shape:

-

Accept Customs

-

Density:

-

7.5-7.6 g Per Cubic Centimetre

-

Sample:

-

Free Sample

-

Packing:

-

Magnetic Isolation Package

Why Choose Us

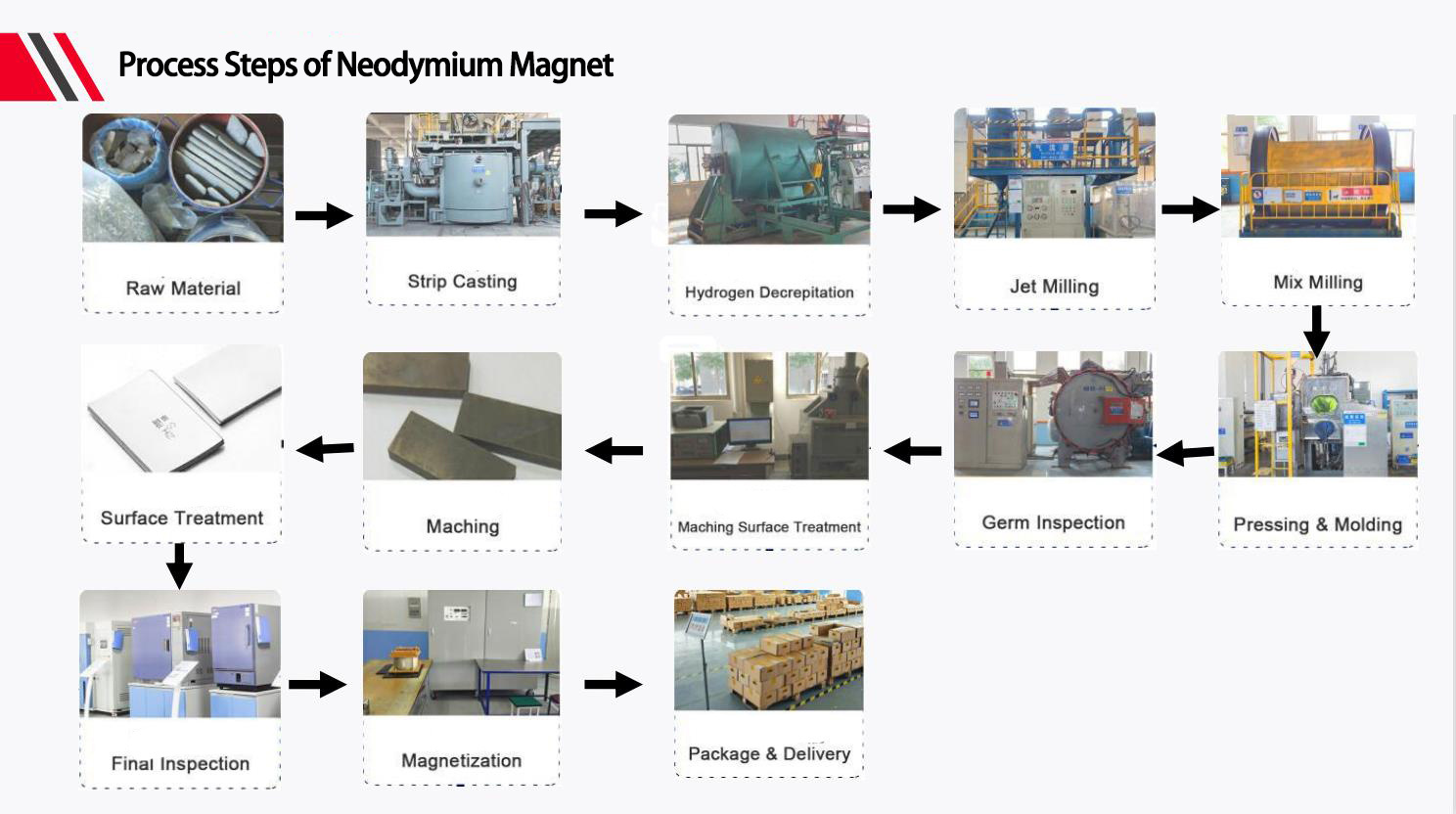

1. FLOW CHART

From the raw material to finished product, all the processes are completed in our factory, and are under our strict control.

2. QUALITY CONTROL

1> Magnet will be inspected strictly during the production of every process.

2> Every magnet will have a certificate before delivery.

3> Magnetic Flux report and Demagnetization Curve can be offered according to request.

3> Magnetic Flux report and Demagnetization Curve can be offered according to request.

3. CORE ADVANTAGE

1> Cutting-Edge TechnologySelf-Developed Key Equipment, Unique Manufacturing Process, Energetic R&D Team.

2> Full Scale Production Capacity 15000 tons, Specialized Factories.

3> The Integrated Industry Supply Chain.

4> Outstanding Product.

2> Full Scale Production Capacity 15000 tons, Specialized Factories.

3> The Integrated Industry Supply Chain.

4> Outstanding Product.

Demagnetization Curve:

4. Excellent Work Environment

We have many large, clean and tidy workshops and production lines. Ensure that the product will not be contaminated during production!

5.Certification, exhibition and business cooperation

1. Our products have dozens of patent certifications. It meets the quality requirements of Europe, America and other countries and has obtained relevant certification.

2. We often participate in various international exhibitions and activities, and have cooperative relations with CRRC, Siemens, Panasonic, Bosch and other domestic and foreign enterprises.

Products Description

Rare Earth Neodymium Magnets

Grades of Neodymium Magnet

Neodymium magnets are all graded by the material they are made of. As a very general rule, the higher the grade (the number following the 'N'), the stronger the magnet. The highest grade of neodymium magnet currently available is N52. Any letter following the grade refers to the temperature rating of the magnet. If there are no letters following the grade, then the magnet is standard temperature neodymium. The temperature ratings are standard (no designation) - M - H - SH - UH - EH.

|

Type

|

Permanent Powerful Neodymium Magnets

|

|

|

|

|||

|

Material

|

Sintered Neodymium Magnets

|

|

|

|

|||

|

Coating

|

Ni, Zn, Epoxy, Parylene, Gold, Passivated, etc

|

|

|

|

|||

|

Shape

|

Block, Bar, Cube, Disc, Ring, Cylinder, Ball, Arc, Trapezoid, etc

|

|

|

|

|||

|

Density

|

7.5-7.6 g/cm³

|

|

|

|

|||

|

Delivery date

|

7-10 days for common samples, 20-25 days for mass produciton

|

|

|

|

|||

|

Magnetic Grade

&

Working Temperature

|

Magnetic Grade

|

|

Working Temperature

|

|

|||

|

|

N35-N45

|

|

80 ℃(176 ℉)

|

|

|||

|

|

N48-N52

|

|

60 ℃(160 ℉)

|

|

|||

|

|

35M-50M

|

|

100 ℃(212 ℉)

|

|

|||

|

|

33H-48H

|

|

120℃(248 ℉)

|

|

|||

|

|

33SH-45SH

|

|

150 ℃(302 ℉)

|

|

|||

|

|

30UH-40UH

|

|

180 ℃(356 ℉)

|

|

|||

|

|

28EH-38RH

|

|

200℃(392 ℉)

|

|

|||

|

|

28AH-33AH

|

|

220 ℃(428 ℉)

|

|

|||

We accept customized services:

1) Shape and Dimension Requirements;

2) Material and coating requirements;

3) Processing according to design drawings;

4)Requirements for Magnetization Direction;

5) Magnet Grade Requirements;

6) Surface treatment requirements(plating requirements)

Coating

1.Neodymium magnets are a composition of mostly Neodymium, Iron and Boron.

If left exposed to the elements, the iron in the magnet will rust.

2.That's why all neodymium magnets in our shop are covered with a protective coating,

which is so thin that it doesn't have any impact on the adhesive force of the magnet.

3.There are many different coating and plating options for neodymium magnets.

The most common coating for neodymium magnets is a nickel plating. While commonly referred to as simply “nickel plating,” this nickel option is actually a three layer plating that comprises of a nickel layer, a copper layer, and a nickel coating. Some other options for coating are zinc, tin, copper, epoxy,silver and gold.

Magnetization Direction

Common direction of magnetization showed in picture bellow:

1> Disc, cylinder and Ring shape magnet can be magnetized Axially or Diametrically.

2> Rectangle shape magnets can be magnetized through Thickness, Length or Width.

3> Arc shape magnets can be magnetized Diametrically, through Width or Thickness.

3> Arc shape magnets can be magnetized Diametrically, through Width or Thickness.

Special direction of magnetization can be customized as required.

Application

The sintered neodymium-iron-boron (NdFeB) permanent magnet

is widely used in permanent magnet servo motor, permanent magnet elevator tractor, wind driven generator, permanent magnet linear motor, permanent magnet step motor, permanent magnet micromotor, permanent magnet oil field motor, permanent magnet transducer, permanent magnet loudspeaker, electronic component, medical equipment,

artificial intelligence

and so on.

Packing & Delivery

1.White inner box.

2.Suitable carton size.

3.Anti-magnetized packaging.

4.We will suggest the best solution of shipment for your reference according to order quantityes.

Our Company

Zhonghang New Material Technology Co., Ltd

was established in 2010. It is a modern national high-tech enterprise specializing in the research and development, production,processing and sales of sintered NdFeB. The company’s production capacity is 4,000 tons, and there are more than 200 employees, including 17 middle and senior R&D technicians. The company has passed the certification of IATF16949 automobile industry quality management system, intellectual property management system, ISO14001 environmental management system, ISO45001 occupational health and safety management system, and is the “hidden champion” enterprise in Zhejiang Province…

FAQ

Q1: Could I get samples?

A: Sure.We usually provide ready sample for free but you need to pay shipping costs or freight collect.

Q2: How about your delivery date?

A: 3-7 days for samples and 15-20 days for mass production.

Q3: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q4: What is the usual payment method?

A: T/T, Paypal, L/C, VISA, e-Checking,Western Union.

Q5: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Hot Searches