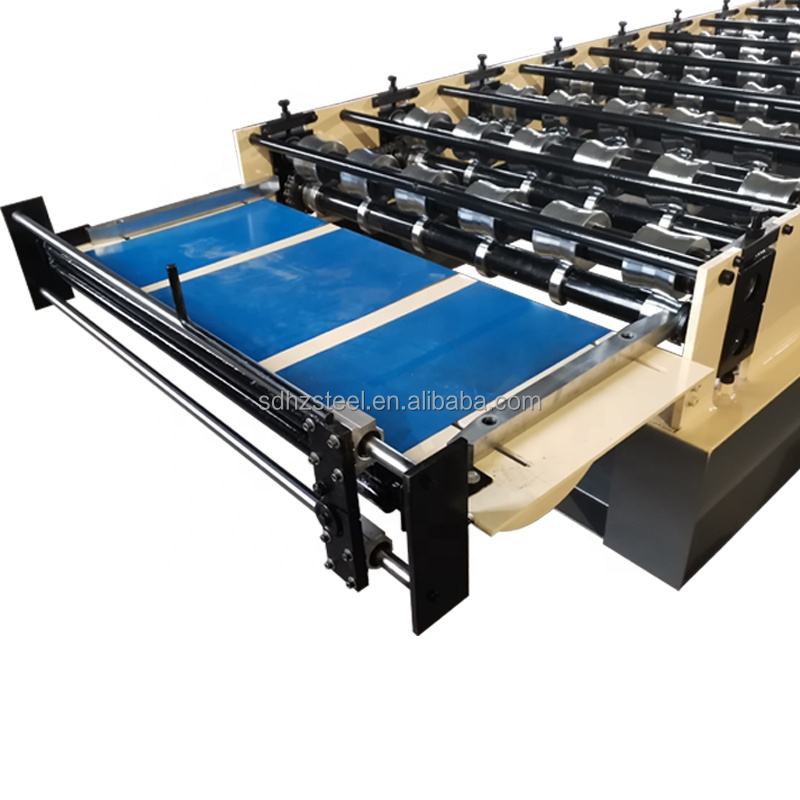

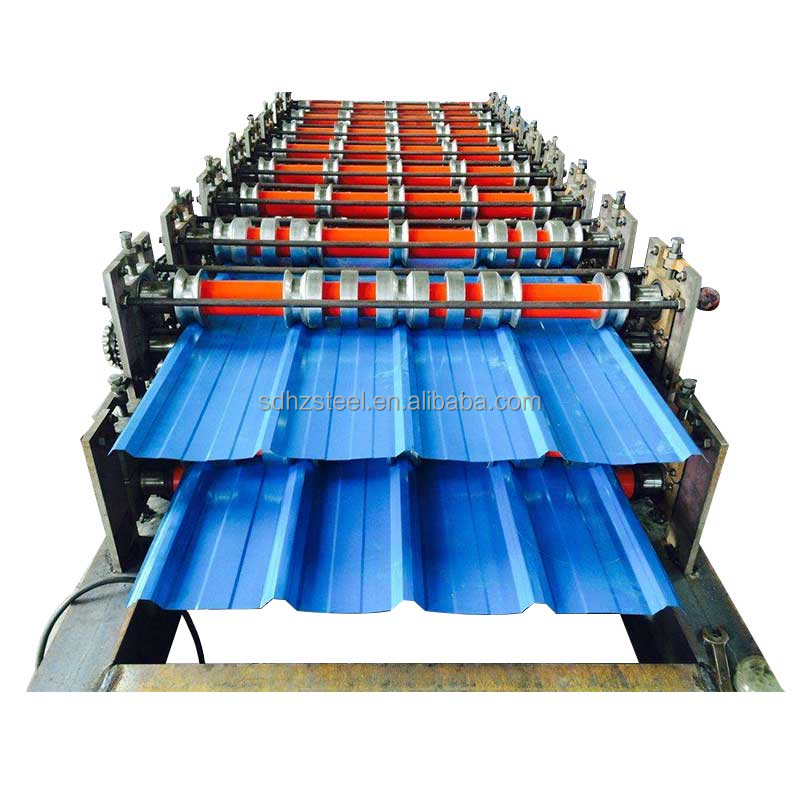

Main forming part

>Rollers: design by senior engineers with Auto-cad software, manufactured with 45# high grade steel by CNC machine tools and

coated with hard chrome

>Shaft: 70mm manufactured with 45# high grade steel by CNC machine tools

>Supporting frame: steel wallboard to guide the forming station bearing basement

>The finished products will change if using different material and thickness

>Driving of machine:by one inch chain

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

HZ

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

800*1200*1300mm

-

Weight:

-

2000 kg

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Roll forming machine

-

Usage:

-

Making tile

-

Raw material:

-

Steel Coil Ppgi Gi

-

Roller material:

-

45#steel Chrome Plated

-

Keywords:

-

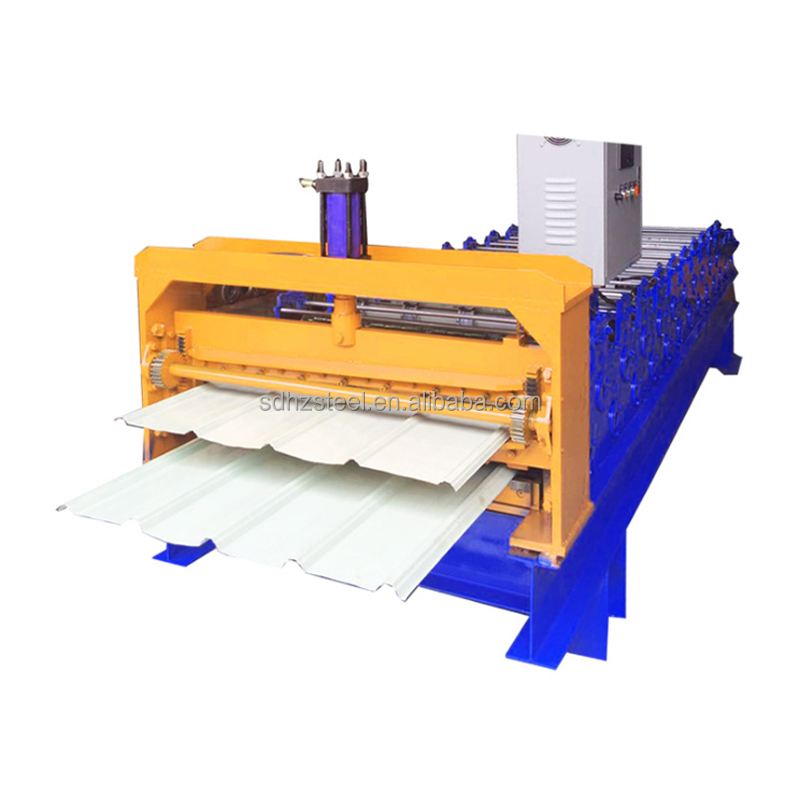

Corrugated Sheet Roof Roll Forming Machine

-

Control system:

-

PLC(imported Brand)

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Name:

-

IBR Roofing Sheet Making Machine

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

HZ

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

800*1200*1300mm

-

Weight:

-

2000 kg

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Roll forming machine

-

Usage:

-

Making tile

-

Raw material:

-

Steel Coil Ppgi Gi

-

Roller material:

-

45#steel Chrome Plated

-

Keywords:

-

Corrugated Sheet Roof Roll Forming Machine

-

Control system:

-

PLC(imported Brand)

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Name:

-

IBR Roofing Sheet Making Machine

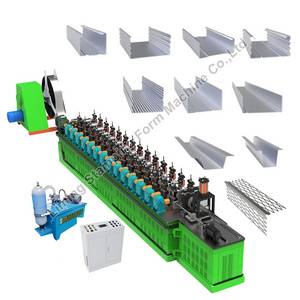

roof ridge tiles building materials machinery metal roof ridge roll forming machine

roofing tile making machine / roll forming machine / glazed tiles roll forming machine

corrugated sheet roll forming machine roofing sheet making machine

Aluminum roofing tile sheet panel roll forming making machine

The hydraulic system parts are all adopts the famous production .

lt can be widely used in village, hotel, exhibition,vocation vallage,family construction and outdoor decorate.

This type of roof sheet has advantage inclouding beautiful,classical appearance and grace taste.

lt uses galvanized steel or aluminum as the material plate.The production speed can be adjustable.

Aluminum roofing tile sheet panel roll forming making machine

The hydraulic system parts are all adopts the famous production .

lt can be widely used in village, hotel, exhibition,vocation vallage,family construction and outdoor decorate.

This type of roof sheet has advantage inclouding beautiful,classical appearance and grace taste.

lt uses galvanized steel or aluminum as the material plate.The production speed can be adjustable.

|

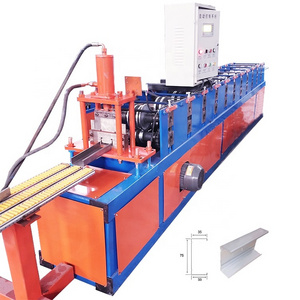

Name of commodity

|

roll forming machine / tile making machine

|

|

Main motor power

|

3kw, 3 phase

|

|

Hydraulic motor

|

3kw

|

|

power Hydraulic

|

10-12MPa

|

|

Pressure Voltage

|

380V /3phase/ 50 HZ (or as your requirement)

|

|

Control System

|

PLC Delta Inverter

|

|

Main Frame

|

300mm H-Beam

|

|

Backboard Thickness

|

14mm

|

|

Chain Size

|

20mm

|

|

Feeding Material

|

color steel coils

|

|

Feeding Thickness

|

0.3-1.2mm

|

|

Productivity

|

8-12m/min

|

|

Roll Station

|

11

|

|

Roller Diameter

|

70mm

|

|

Roller material

|

45# steel

|

|

Cutter material

|

Cr12 , quenched

|

|

Cr-Plating Size

|

0.05mm

|

|

Overall Size

|

3000×800×1000mm

|

|

Components

|

Manual Uncoiler-------------------1 set Guiding Platform------------------1 set Coil Strip Leveler------------------1 set Main

machine of Roll Forming------1 set Electric-Motor---------------------1 set Cutting Device--------------------1 set Hydraulic Station------------------1 set PLC Control-----------------------1 set Supporter Table-------------------1 set |

|

Workflow

|

Manual decoiling----feeding and guiding----roll forming----cut to length----run out table

|

|

Payment terms

|

T/T(30% T/T pay in advance, the remaining 70% pay before ship)

|

|

Delivery time

|

30 working days later after receiving the deposit

|

FAQ:

1. Q: Are you a manufacturer?

A:Yes, we are manufacture since 1996 with four branch factories.

2. Q: How should I do if I would like to order my machine?

A: Send me your design drawing if you have. Or tell me your design idea. I arrange my engineer to drawing it for your

confirmation.

3. Q: What details of the machine you should get from me?

A: I will confirm all details with you, such as the voltage in your city.

4. Q: I am new in this field. How could i understand the machine very well?

A: We can send manual and vedios and online help.

5. Q: I receive a lot of quotations, they are big range, How could i choose?

A: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for

contacting with me.

6. Q: Can you give me one suggestion for ordering the machine?

A: No problem. Do not trust your eyes when you see beautiful pictures of machines or factories. More when you contact.

7. Q: I have not whatsapp and skype, how could I contact with you?

A: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

8. Q: What do you think what is the most important for roll forming machine?

A: Drawing ! Drawing ! Drawing.

9. Q: Can you use other brand of spare parts for me if i want?

A: No problem if you want to pay the money.

A:Yes, we are manufacture since 1996 with four branch factories.

2. Q: How should I do if I would like to order my machine?

A: Send me your design drawing if you have. Or tell me your design idea. I arrange my engineer to drawing it for your

confirmation.

3. Q: What details of the machine you should get from me?

A: I will confirm all details with you, such as the voltage in your city.

4. Q: I am new in this field. How could i understand the machine very well?

A: We can send manual and vedios and online help.

5. Q: I receive a lot of quotations, they are big range, How could i choose?

A: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for

contacting with me.

6. Q: Can you give me one suggestion for ordering the machine?

A: No problem. Do not trust your eyes when you see beautiful pictures of machines or factories. More when you contact.

7. Q: I have not whatsapp and skype, how could I contact with you?

A: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

8. Q: What do you think what is the most important for roll forming machine?

A: Drawing ! Drawing ! Drawing.

9. Q: Can you use other brand of spare parts for me if i want?

A: No problem if you want to pay the money.

Hot Searches