for metal surface deburring, and polishing after laser process.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2100

-

Working width:

-

30-800(RW-800)

-

Processing thickness:

-

0.5-100mm

-

feeding speed:

-

0-5m/min(frequency control)

-

Brush roller(W) qty and size:

-

01300*300mm 4pcs

-

Self-rotating speed:

-

0-1200r/min(frequency control)

-

Revolution speed:

-

0-25r/min(frequency control)

-

Revolution motor:

-

0.75kw

-

Self rotation motor:

-

2.2kw*2

-

Vacuum power:

-

7.5kw

-

Total power:

-

25.89

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YOWING

-

Power (kW):

-

36.42

-

Weight (KG):

-

2100

-

Working width:

-

30-800(RW-800)

-

Processing thickness:

-

0.5-100mm

-

feeding speed:

-

0-5m/min(frequency control)

-

Brush roller(W) qty and size:

-

01300*300mm 4pcs

-

Self-rotating speed:

-

0-1200r/min(frequency control)

-

Revolution speed:

-

0-25r/min(frequency control)

-

Revolution motor:

-

0.75kw

-

Self rotation motor:

-

2.2kw*2

-

Vacuum power:

-

7.5kw

-

Total power:

-

25.89

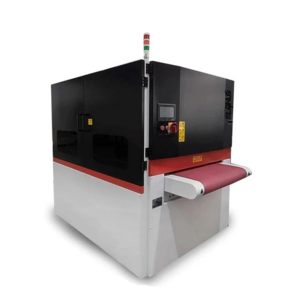

High Precision Metal Deburring Sanding Polishing Machine with Polishing edge rounding after CNC lathe cutting

Deburring

is a process that removes burrs, or small protuberances, from the surface of a sheet metal part. Burrs are typically formed during the cutting or machining process and can have sharp edges that can cause problems during handling or use of the part. Deburring is important for several reasons:

Safety:

Burrs can cause cuts or other injuries if someone handles the part without proper protection. Deburring removes these sharp edges, making the part safer to handle.

Quality: Burrs can affect the fit and function of the part. For example, a burr on a mating surface could prevent the parts from fitting together properly. Deburring ensures that the parts will fit and function as intended.

Appearance: Burrs can affect the appearance of the part and make it look unfinished or poorly made. Deburring helps to improve the overall appearance of the part.

There are several methods for deburring sheet metal parts, including hand deburring, mechanical deburring, and abrasive blasting.The appropriate method will depend on the size and shape of the part, as well as the materials and tolerances involved.

Specification

|

Model

|

RW-630

|

RW-800

|

RW-1100

|

RW-1300

|

|||

|

Working width

|

30-630mm

|

30-800mm

|

30-1100mm

|

30-1300mm

|

|||

|

Working thickness

|

0.5-100mm

|

7.5kw

|

11kw

|

|

|||

|

Feeding speed

|

0-5m/min (frequency control)

|

7.5kw

|

11kw

|

|

|||

|

Rotary brush size and qty

|

φ300*300mm 4 pcs

|

0.37kw*5

|

6 pcs

|

8 pcs

|

|||

|

Self rotating speed

|

0-1200r/min (frequency control)

|

|

|

|

|||

|

Self rotating motor

|

1.5kw*2

|

2.2kw*2

|

2.2kw*1+2.2kw*2

|

2.2kw*4

|

|||

|

Revolution speed and motor

|

0.75KW*1 0-25r/min (frequency control)

|

1.5KW

|

3.0kw

|

|

|||

|

R roller motor

|

11kw

|

11kw

|

15kw

|

22kw

|

|||

|

R roller rotating speed

|

0-16m/min

|

|

7 kg/cm2

|

|

|||

|

W Brush roller lifting motor

|

0.37kw

|

|

|

|

|||

|

Working table lifting motor

|

0.37kw

|

|

|

|

|||

|

Feeding motor

|

1.5kw

|

1.5kw

|

1.5kw

|

1.5kw

|

|||

|

Vacuum motor

|

7.5kw

|

7.5kw

|

7.5kw

|

11kw

|

|||

|

Total power

|

25.89

|

25.89kw

|

32.09kw

|

39.27kw

|

|||

|

Machine size

|

2800*1500*2250mm

|

2800*2000*2250mm

|

2800*2000*2250mm

|

2800*2000*2250mm

|

|||

|

Machine weight

|

2000kg

|

2300kg

|

2600kg

|

3000kg

|

|||

Product Description

Machine Details

RW series inside view

Metal Deburring machine is used

Oxide Layer Removal

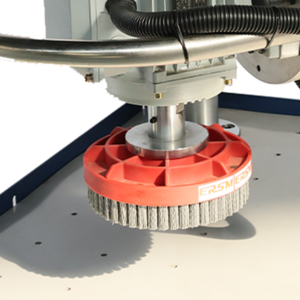

Oxide skin occurs on metal and stainless and aluminium sheet after laser cutting and drilling and welding.This roller is to remove for subsequent coating.

Rotary Brush W roller

3M pollishing roller could help realize high polishing effect.

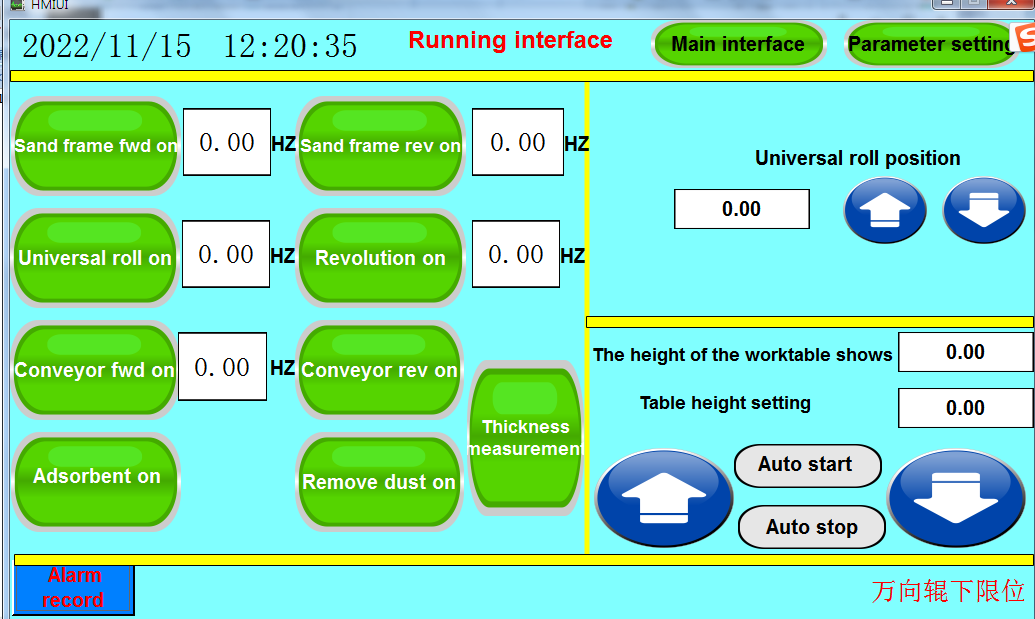

Touch screen fully automatic.

touch screen with humanized operation interface and direct data is easy to operate and adjusted.

Delta and famous electric parts

Good quality electric parts ensure stable working and long lifespan.

Vacuum Absorbtion Table .

It is flat belt conveyor with holes to ensure small pcs are sucked and kept stable when working.

Application of Scope

* Removal of burrs on laser, water-jet, punched, and cut metal parts.

* Provide the finest finish in the industry

* Deburr, edge break, & finishing of metal in one pass

* Mixing of metals, including titanium, aluminum, carbon & stainless steel, copper, etc.

* Provide the finest finish in the industry

* Deburr, edge break, & finishing of metal in one pass

* Mixing of metals, including titanium, aluminum, carbon & stainless steel, copper, etc.

Related Products

RW Series

Drum Roller+ Rotary Brush

√

Deburring √Edge rounding

√Laser oxide removal √Finishing

Extra Head R for √Deburring

√Laser oxide removal √Finishing

Extra Head R for √Deburring

RMD Series

Drum Roller + Disc Rollers

√Deburring√Slag Removal

√Edge Rounding

√Edge Rounding

√Finishing

MDB Series

Disc Rollers+Brush Roller

√Slag Removal √Laser Oxide Removal √

Edge rounding

√Finishing

Extra Head B for √Fine Polishing

Extra Head B for √Fine Polishing

Company Profie

"YOWING MACHINERY,Located in China woodworking machinery important town: Lunjiao, Focusing on the development of full range of furniture and wooden door machinery equipment,providing furniture and wood door companies with solutions for whole factory planning and automatical production lines,presenting our customers with excellent quality,efficient and stable products and high-quality service.

Yowing machinery, under all colleagues hardworking,our machines sold very well domestic and abroad,our services has been to almost 20 countries including asia, Russia, Brasil and Mexico,ETC.In 2018,We built up a service office in Binh Duong, Vietnam, and created a professional service team, to make sure can prove immediate service for our domestic and abroad customers.

2019,Yowing machinery, in order to help solve sanding difficulties, we start import and sell Origin of Italy Profile sand, provide more proper sanding materials for wood sanding, and metal sanding.2020, we will continue searching high quality overseas sanding materials, matching chinese machines and equipments, give one more option to our customers!"

Packing & Delivery

FAQ

1.How can i get the price?

-We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

2.What is your lead time?

-It depends on the order quantity and the season you place the order.

Usually we can ship within 7-15 days for small quantity,and about 30 days for large quantity.

3.What is your payment term?

-T/T,Western Union,MoneyGram,and Paypal.This is negotiable.

4.What is the shipping method?

-It could be shipped by sea,by air or by express(EMS,UPS,DHL,TNT,FEDEX and ect).Please confirm with us before placing orders.

5

.How do you make our business long-term and good relationship?

-1. We keep good quality and competitive price to ensure our customers benefit ;

-2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Hot Searches