- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yongda

-

Power (kW):

-

120

-

Weight (KG):

-

300

-

Core Components:

-

IGBT module

-

Machine Type:

-

Pipe and Tube Bending Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

ISO 9001:2000

-

Input current:

-

6-200A

-

Core parts:

-

IGBT modules

-

Voltage:

-

320V-420V customized

-

nature of us:

-

manufacturer since 1996

-

Warrant:

-

12 months

-

Cooling method:

-

Water cooling machine

-

Model Number:

-

WZP-200

Quick Details

-

Max. Bending Angle (Deg):

-

90

-

Bending Precision (Deg):

-

0.3

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yongda

-

Power (kW):

-

120

-

Weight (KG):

-

300

-

Core Components:

-

IGBT module

-

Machine Type:

-

Pipe and Tube Bending Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

ISO 9001:2000

-

Input current:

-

6-200A

-

Core parts:

-

IGBT modules

-

Voltage:

-

320V-420V customized

-

nature of us:

-

manufacturer since 1996

-

Warrant:

-

12 months

-

Cooling method:

-

Water cooling machine

-

Model Number:

-

WZP-200

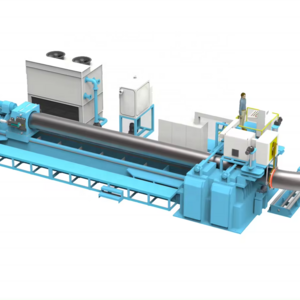

Hot induction pipe bending machine for sale

Technial parameters of hot induction pipe bending machine for sale

|

Model |

WZP-200

|

|

Work power |

3 phase 380V+/-10%, 50-60HZ |

|

Input voltage |

320V-420V can be changed, depend on your country's electric power |

|

Input current |

6-200A |

|

Input power |

6-120KW(power adjusted stepless) |

|

Oscillation frequency |

15-30 KHZ or 2-10KHZ (customized)

|

|

Cooling water pressure |

0.3 MPA |

|

Size of geneartor: Transformer |

850*600*1330 780*540*520mm |

|

Weight of generator ; transformer |

131kgs; 89kgs |

|

Water cooling protection point |

Below 50 degree celsius |

Features of hot induction pipe bending machine

1, my company transistor (IGBT) high frequency power-saving than vacuum tube up to 40-60%, saving 60%, external support facilities to reduce investment by 75%.

2, a unique cooling circulation system, ensure that the equipment 24 hours of continuous work.

3, small size, light weight, easy to move, no million-volt high-voltage danger, safe operation.

4, high reliability, easy to maintain and improve the over voltage, over current, overheating, lack of, water and other self-protection.

5, use large scale integrated circuit digital automatic control, with manual, automatic, semi-automatic, and the lack of heat insulation of cold sub-time control functions.

6, automatic frequency tracking, stepless power adjustment, easy to use, 10 minutes to learn to use.

7, the company has a complete sales service system and the treatment of professional engineers, to ensure that you have no worry about technology or service.

Composition of machine: One generator and one transformer

Accosseries: induction coils, foot switch,installing and operating instructions

Control system of induction pipe bending machine

Over voltage, over current, overheating, lack of water and other alarm indicator, and automatic control and protection .

More applications

Product qualtiy certifications: ISO9001-2000

Product qualtiy certifications: ISO9001-2000

Packing for hot induction pipe bending machine:

Two wooden cases (plywood) Inside,will be filled with plastic foam,for waterproof and shockproof.

Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air.

1. Reply your inquiry within 24 working hours

2. Experienced engineer instruct and sales communicate with you in fluent English.

3. According to work pieces specifications, heating requirements, propose best solutions,also reference your ideas.

4. Machine details and working video link for your reference

5. Competitive price ,compare with the same industry

6. Production: strict quality standard, to produce machine and induction coils.

7. Debugging machine and only good machine will be sent.

8. Tracking goods shipping and provide bill of lading,invoice,packing list and other documents what you need

9. Provide install and technology instruction by sending drawings, email, or telephone,video.

10.If you need, will arrange one engineer to your place,instruct install machine and training operators.

11.Excess warranty period(12 months warranty), you can buy the spare parts from us with special discount price.

12.Provide long-terms technical support